Device for intelligently monitoring state of shearer picks based on linear Hall multi-probe structure

An intelligent monitoring and shearer technology, which is applied to mining equipment, cutting machinery, mining equipment, etc., can solve the problems of not being able to detect broken teeth and damage of shearer picks in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

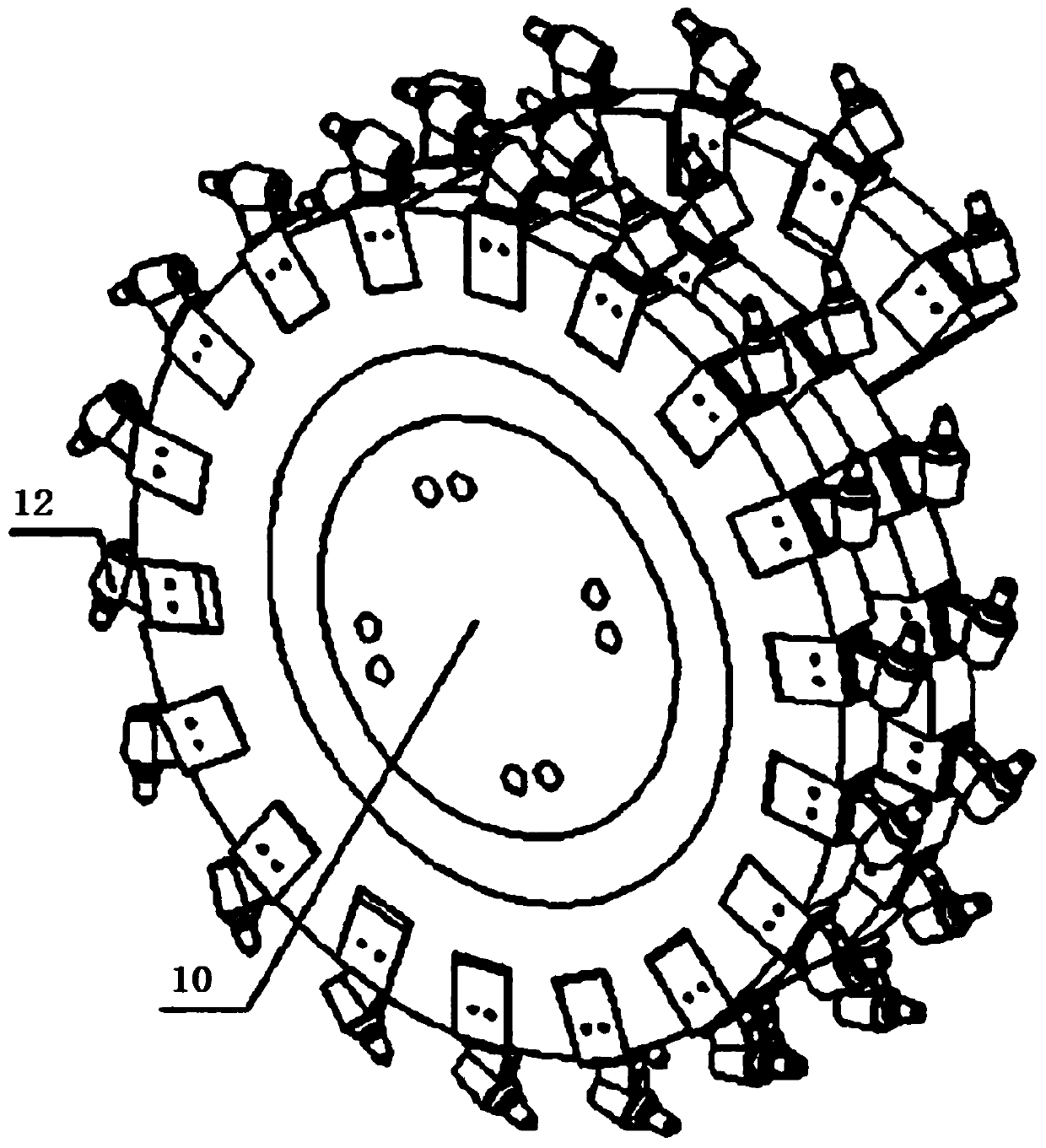

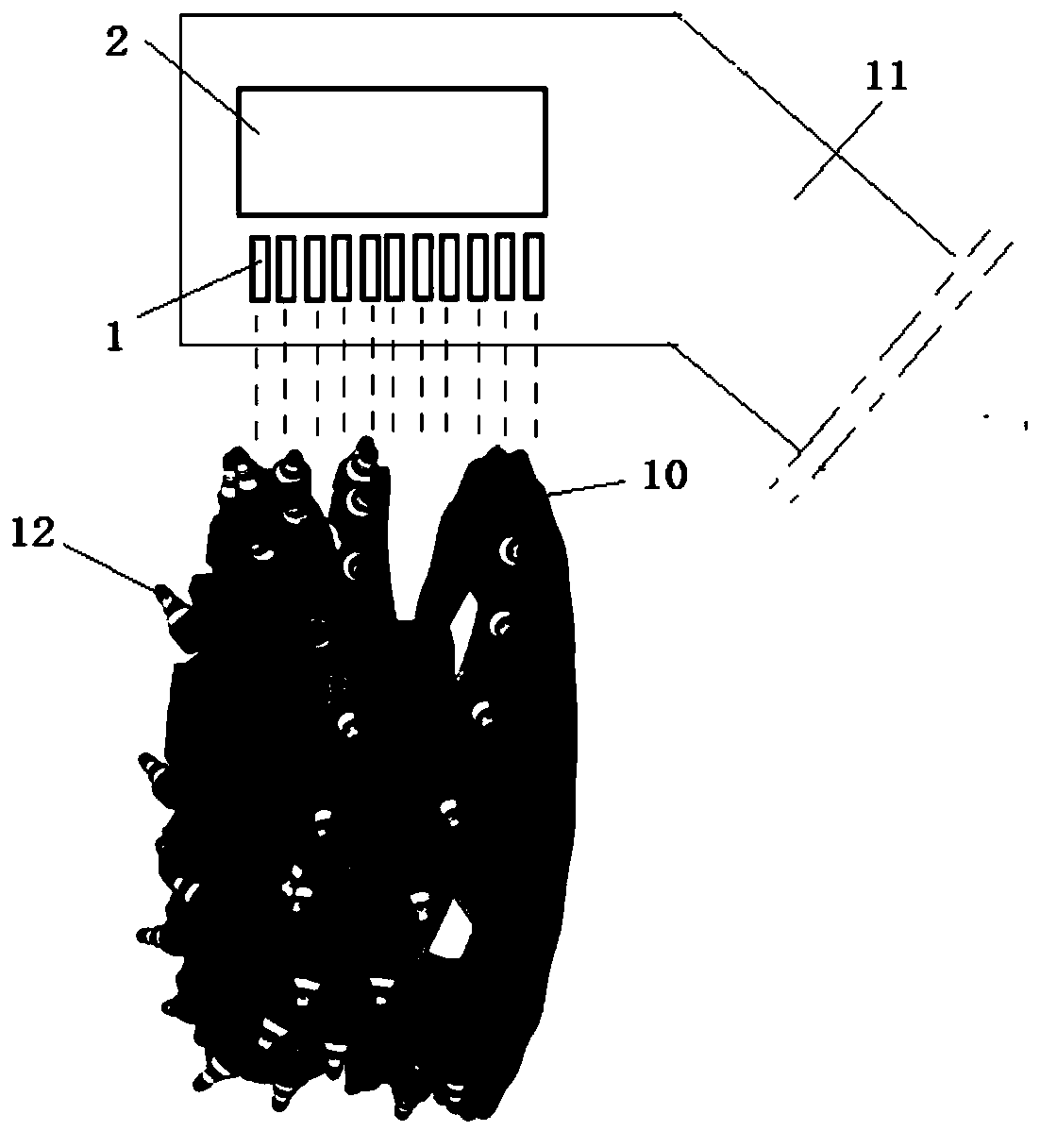

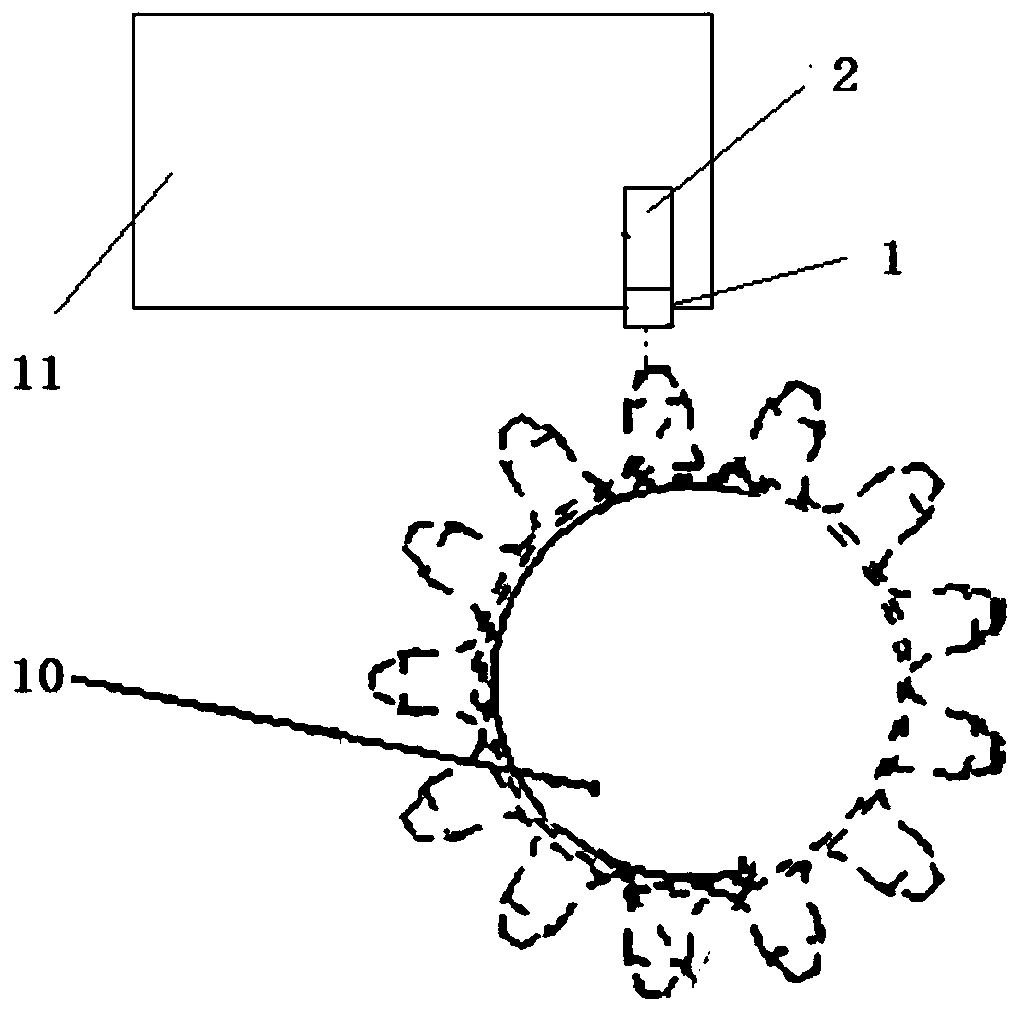

[0008] Specific implementation mode one: refer to Figure 1 to Figure 9 Specifically illustrate this embodiment, the intelligent monitoring coal shearer pick state device based on the linear Hall multi-probe described in this embodiment consists of multiple Hall elements 1, permanent magnets 2, multiple signal amplifier circuits 3, multiple A / D conversion circuit 4, controller circuit 5 and wireless signal sending device 6;

[0009] The plurality of Hall elements 1 are arranged in parallel in a row, the permanent magnets 2 are arranged at the rear ends of all Hall elements 1, and the signal output end of each Hall element 1 is connected to the signal input end of a signal amplifier circuit 3, each The signal output end of each signal amplifying circuit 3 is connected to the signal input end of an A / D conversion circuit 4, and the signal output end of each A / D conversion circuit 4 is connected to a signal input end of the controller circuit 5, and the signal output end of the ...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment is further described on the basis of Embodiment 1. In this embodiment, the A / D conversion circuit 4 is a high-speed A / D sampling chip (model is AD7705 / 06). After amplifying and processing the signal output by the Hall element, a series of signals are obtained after processing by a high-speed A / D sampling chip. By comparing the collected signals, the state of the pick can be judged.

specific Embodiment approach 3

[0018] Specific implementation mode three: the following combination Figure 4 This embodiment will be specifically described. This embodiment is further described on the basis of Embodiment 1, and it also includes a parking signal output device 20, the signal input end of the parking signal output device 20 is connected to the signal output end of the controller circuit 5, and the signal output end of the controller circuit 5 The signal output end is connected to the power supply controller of the coal shearer. With such arrangement, the present invention will directly stop the working state of the shearer pick when the tooth breakage and damage of the pick are detected, and adopt intelligent braking measures to avoid production accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com