Prefabricated pipe joint structure for pipe-jacking method tunnel hole opening and using method thereof

A pipe jacking method and pipe joint technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as poor connection and water-stop effects, structural collapse, and high construction risks, and achieve overall structural stress and waterproof performance Good, the effect of improving the accuracy and efficiency of opening holes and reducing the risk of opening construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

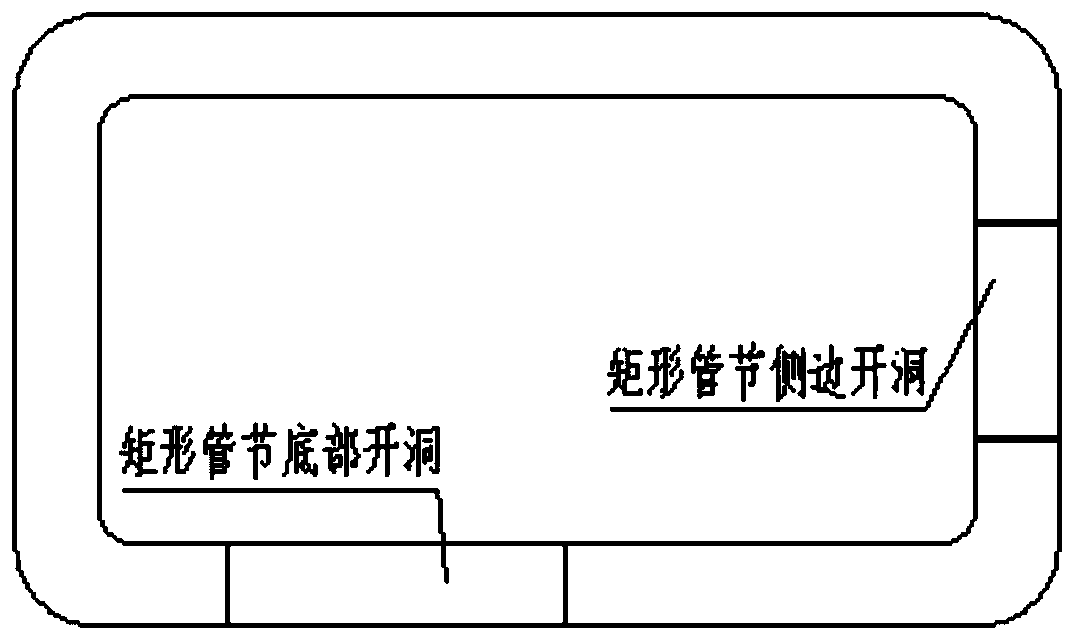

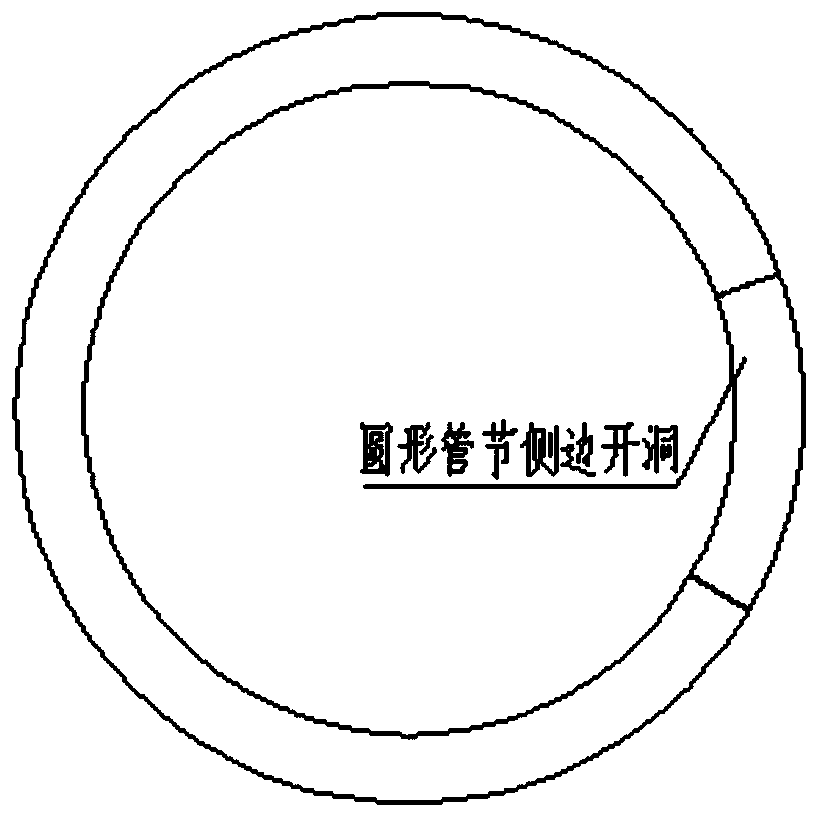

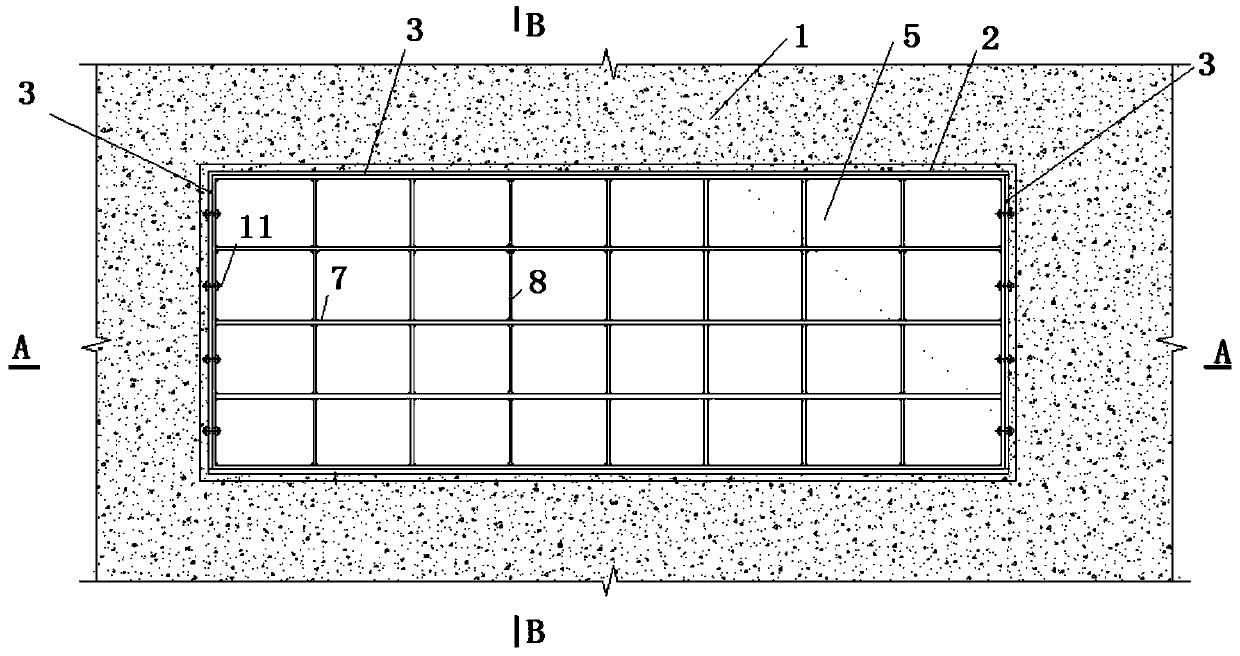

[0042] Such as Figure 3 to Figure 6 As shown, the prefabricated pipe joint structure used for tunnel opening by pipe jacking method includes pipe joint main body 1, and the side wall of pipe joint main body 1 is provided with holes 2.

[0043] Wherein, the hole 2 is provided with a pre-embedded steel grating 5, and the pre-embedded steel grating 5 is used to bear the load of the side wall of the pipe joint main body 1 where the hole 2 is located;

[0044] The side wall of the hole 2 is provided with a pre-embedded steel plate 3; the pre-embedded steel plate 3 is fixed with the stressed steel bar of the pipe joint main body 1 through the pre-embedded steel plate anchor bar 4;

[0045] The embedded steel grating 5 includes an outer frame 6 matching the hole 2, and a grid-like bearing part arranged in the outer frame 6;

[0046] The embedded steel grating 5 forms a detachable connection between the outer frame 6 and the embedded steel plate 3 by means of some bolt connections a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com