Unit circulation type pressure injection and extraction integrated gas extraction system and method

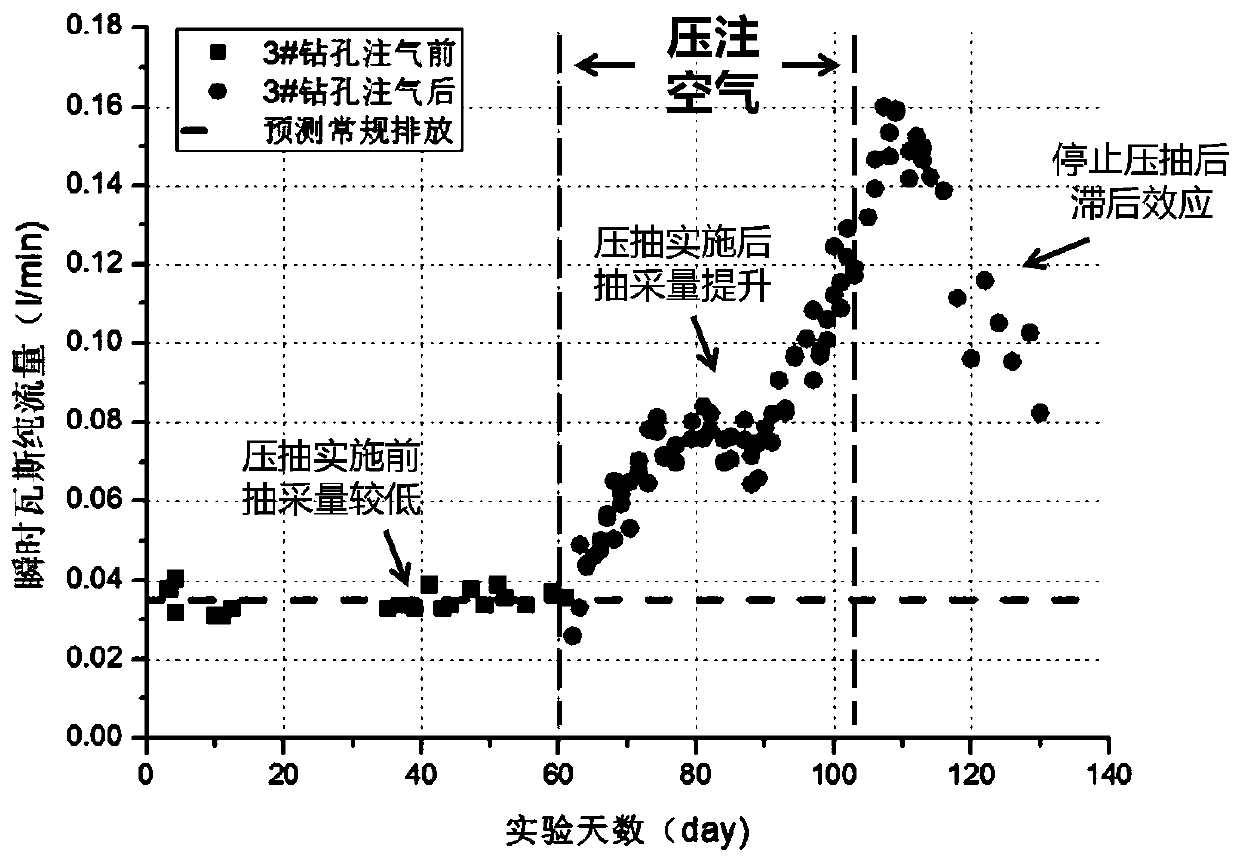

A gas drainage and circulation technology, which is applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve the problems of difficult service coal seams, gas drainage concentration reduction, and economic value decline, so as to ensure the uniformity of the drainage effect, Improve the extraction concentration and promote the extraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

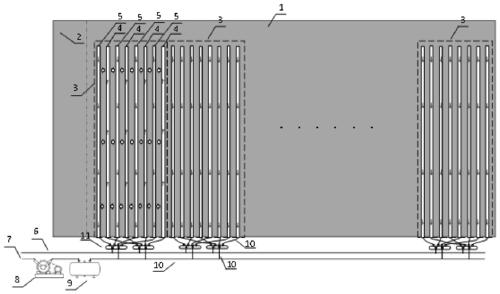

[0061] combine Figure 1 to Figure 7 As shown, the present embodiment provides a unit circulation pressure-extraction integrated gas drainage system, including: a gas booster device 8, a high-pressure gas storage control device 9, a pressure-extraction manifold 11 and several pressure-extraction manifolds distributed in the coal seam 1 pumping unit 3;

[0062] Each pumping unit 3 comprises: a first pumping subunit 4 and a second pumping subunit 5, the boreholes of the first pumping subunit 4 and the boreholes of the second pumping subunit 5 alternate layout.

[0063] Each pumping unit 3 is correspondingly equipped with two pumping manifolds 11, one of which is connected to the drilling holes of all the first pumping subunits 4 of the pumping unit 3, and the other manifold is 11 is connected to the boreholes of all the second pumping sub-units 5 of the corresponding pumping unit 3 . The pressure-extraction manifold 11 is respectively connected with the extraction main pipeli...

Embodiment 2

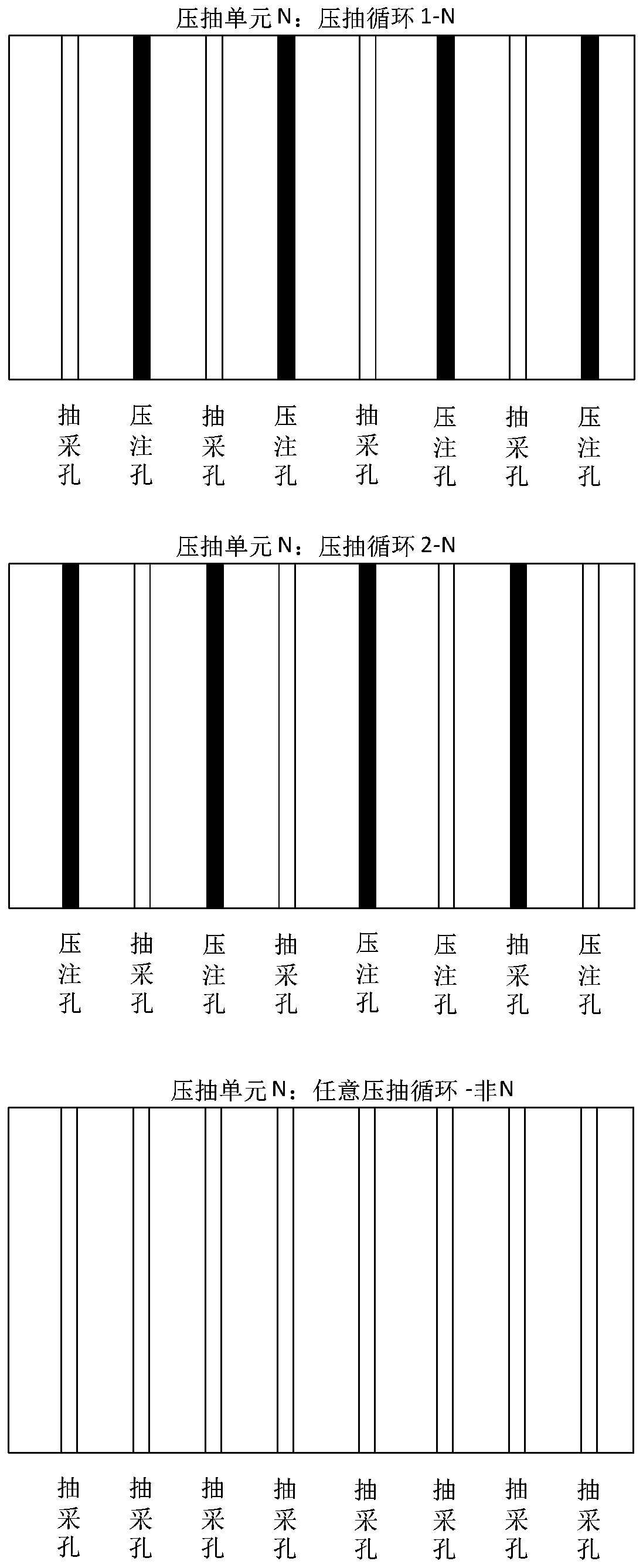

[0068] On the basis of the above-mentioned first embodiment, this embodiment also provides a unit circulation pressure-extraction integrated gas drainage method, including:

[0069] S1. Divide the coal seam into N pumping units 3 . The number of units N is calculated by the following formula:

[0070]

[0071] In the formula, M is the total number of drilling holes in a mining face, q max is the rated standard output flow rate of the booster device, q is the required flow rate per unit length (1m) of boreholes for effective pumping, and is measured by the laboratory, L is the average length of a single drainage borehole, and 1.2 is the redundancy factor.

[0072] S2. Calculate the up-to-standard extraction volume Q of each extraction unit according to the original gas content of the coal seam, the up-to-standard gas content in drainage and the condition parameters of the coal seam N达标 . The up-to-standard extraction volume Q of each pumping unit 3 N达标 Calculated by:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com