Mortar stirring and spraying system for squarer

A mortar mixing and spraying system technology, used in work accessories, fine work devices, stone processing equipment, etc., can solve problems such as inability to meet production requirements, inability to meet mortar concentration, and difficult to control cutting quality, reaching a large market. Value and promotion value, optimize cutting process, ensure the effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

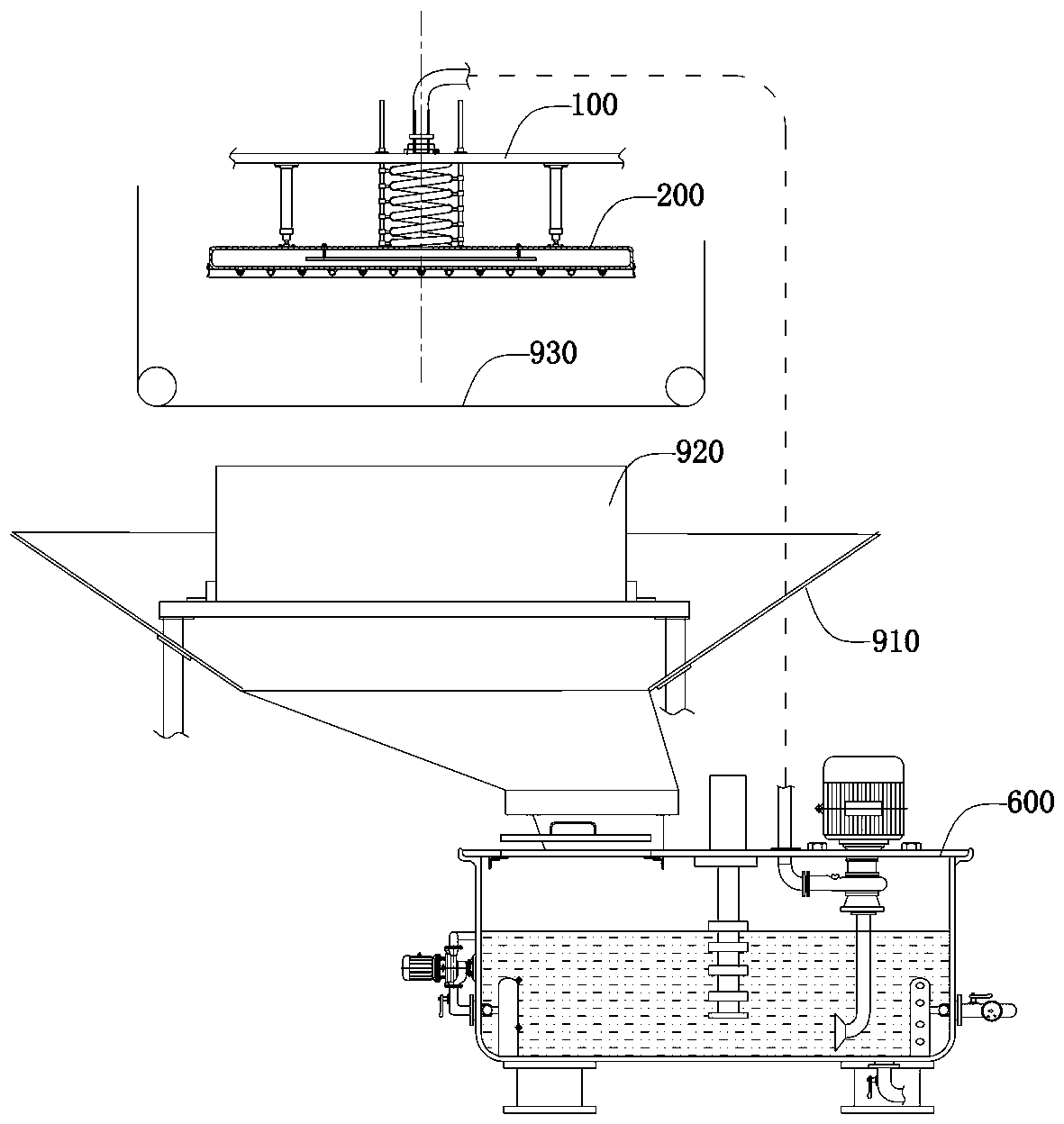

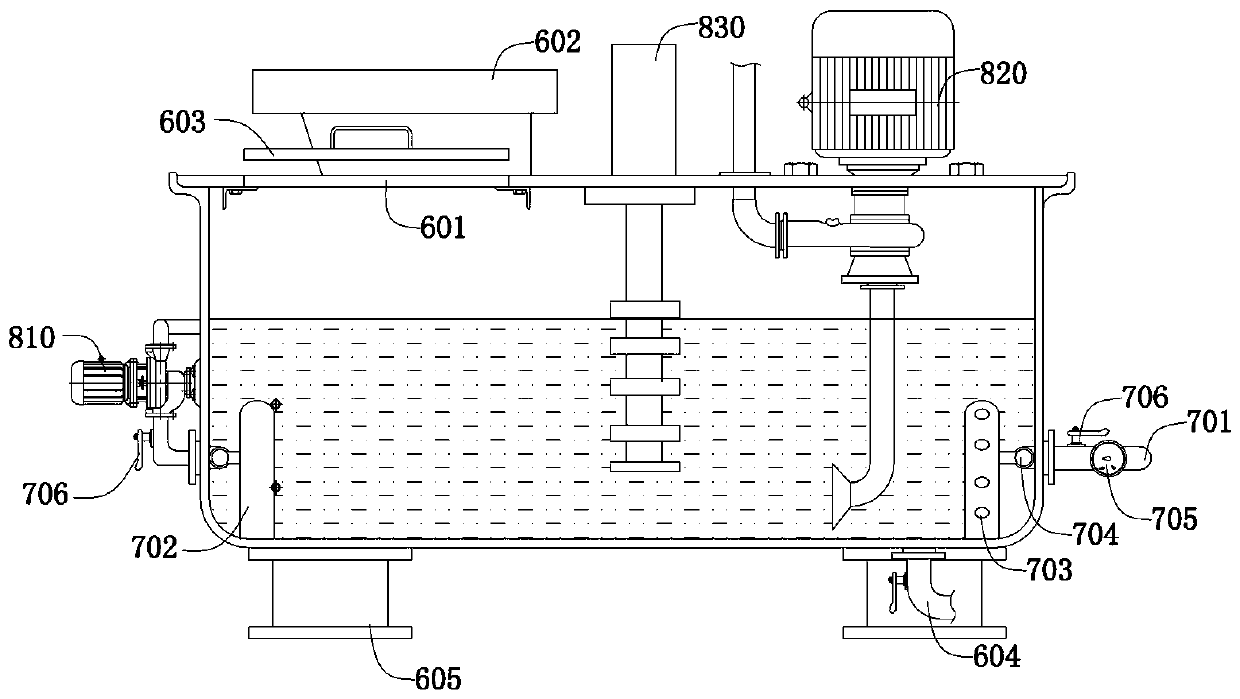

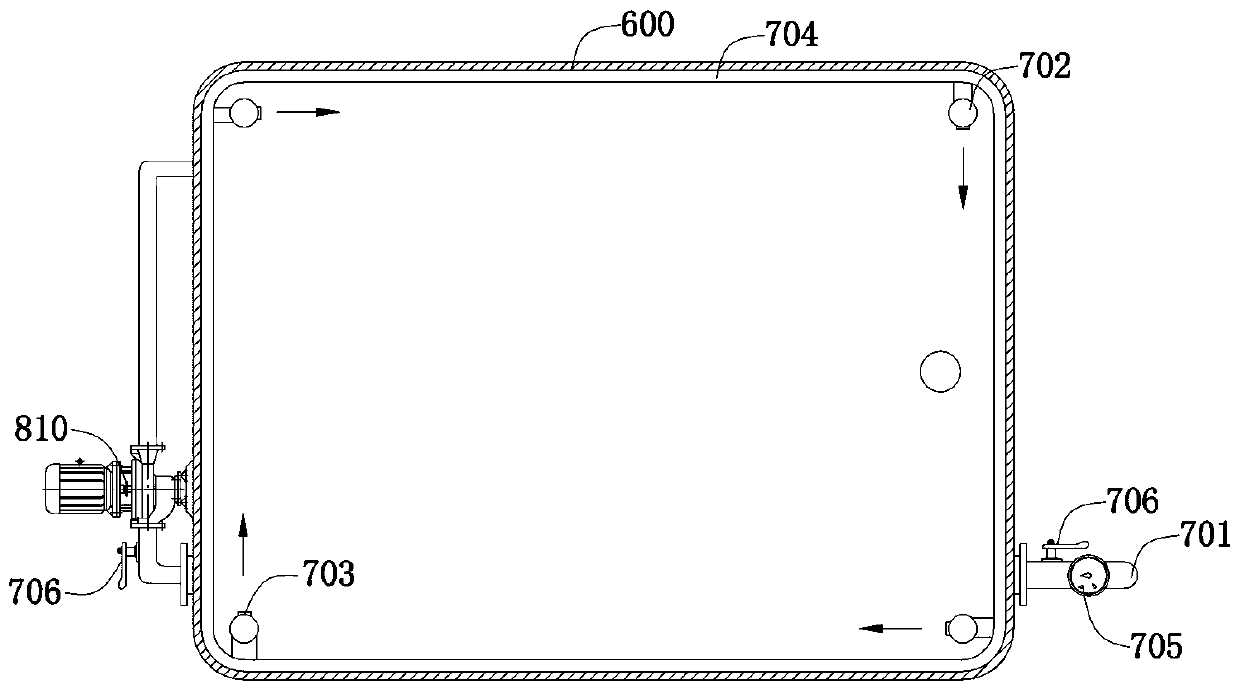

[0026] see Figure 1-Figure 6 , a mortar mixing and spraying system for a square cutter of the present invention, comprising a top bracket 100, a liquid supply tank 200, and a mortar mixing tank, the lower part of the liquid supply tank is provided with a lower edge plate 300, an air flow pipe 400 and an adjustable mortar The flow pipe 500 and the top bracket 100 are fixedly provided with a slurry supply pipe 101; between the liquid supply tank 200 and the top bracket 100, a lifting power push rod 102 and a telescopic tube 103 are arranged, and the telescopic tube 103 communicates with the liquid supply tank 200 and the supply tube. The slurry pipe 101, and the telescopic pipe 103 is in a spiral shape, and a guide slide bar 104 is arranged between the liquid supply tank 200 and the top support frame 100. The rod matches the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com