Device and method for detecting lens aberration of lithography machines

A detection device and lithography machine technology, which is applied in the direction of photolithography exposure device, micro-lithography exposure equipment, etc., can solve the problem that the defect in the local area of the lens is difficult to be found, the problem of the lens of the lithography machine equipment is found, and all parts are detected and other problems to achieve the effect of improving monitoring capabilities, shortening detection time, and simplifying detection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

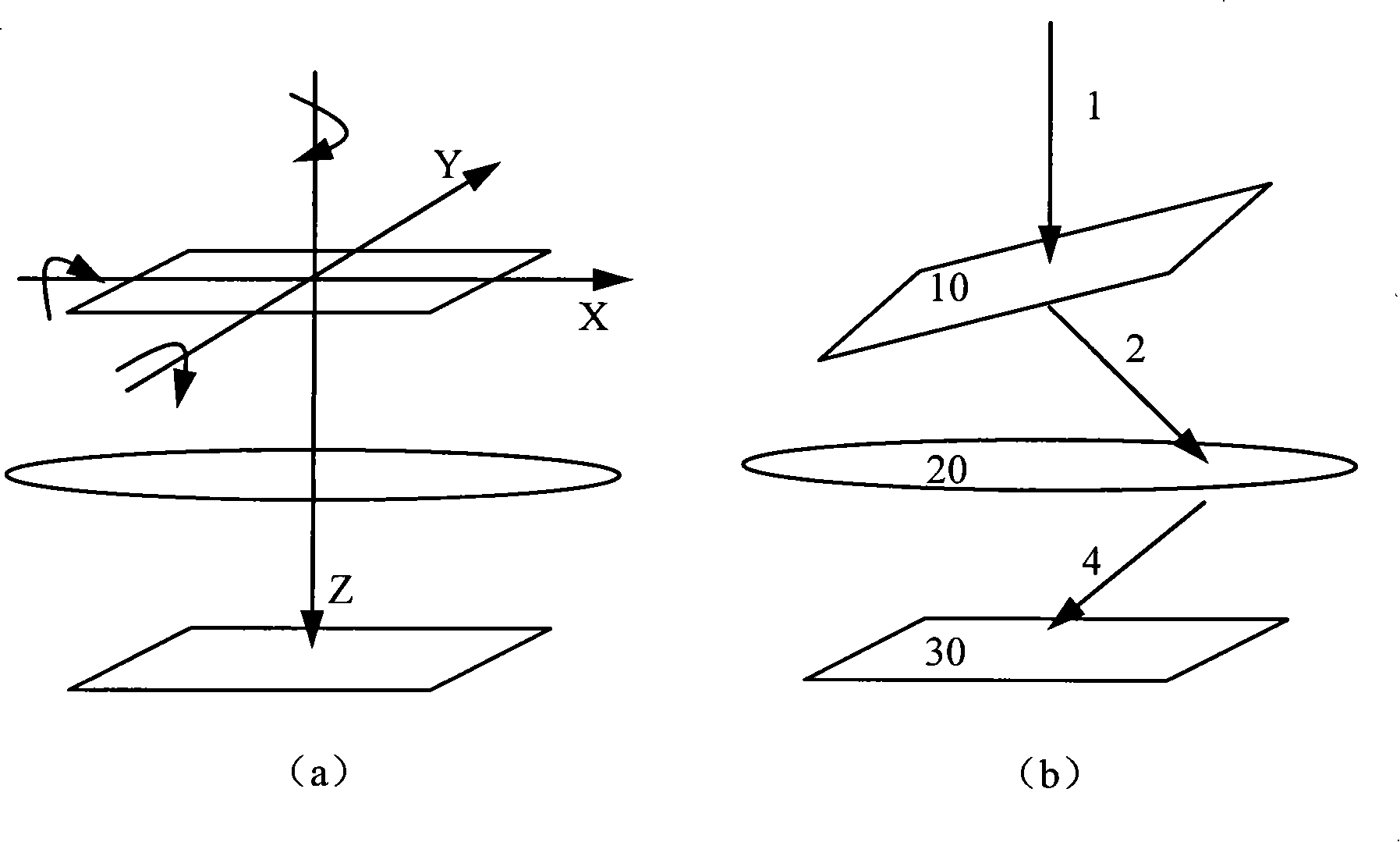

[0030] see image 3 (b), the detection device of the lens aberration of the lithography machine of the present invention comprises:

[0031] An incident light generating device (not shown), emitting incident light 1;

[0032] An imaging lens 20, the main lens of the photolithography machine is selected;

[0033] A transmission grating 10 and a silicon wafer platform 30, the grating 10 and the silicon wafer platform 30 are respectively placed on both sides of the optical path of the lens 20;

[0034] A detector (not shown), integrated on the silicon wafer platform 30 , measures the position, shape, size and focal length of the focal point formed on the silicon wafer platform 30 by the refracted light passing through the lens 20 .

[0035] see Figure 4 (b), this is another embodiment of the detection device for the lens aberration of the lithography machine of the present invention, which is the same as image 3 The difference is that the transmission grating 10 is replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com