Water pump bearing with double-row balls

A technology of water pump shaft and double row ball, applied in the direction of shaft and bearing, bearing, bearing components, etc., can solve the problems of unfavorable product promotion and use, increase product use cost, unfavorable maintenance and replacement, etc., to ensure smooth operation and guaranteed use effect. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

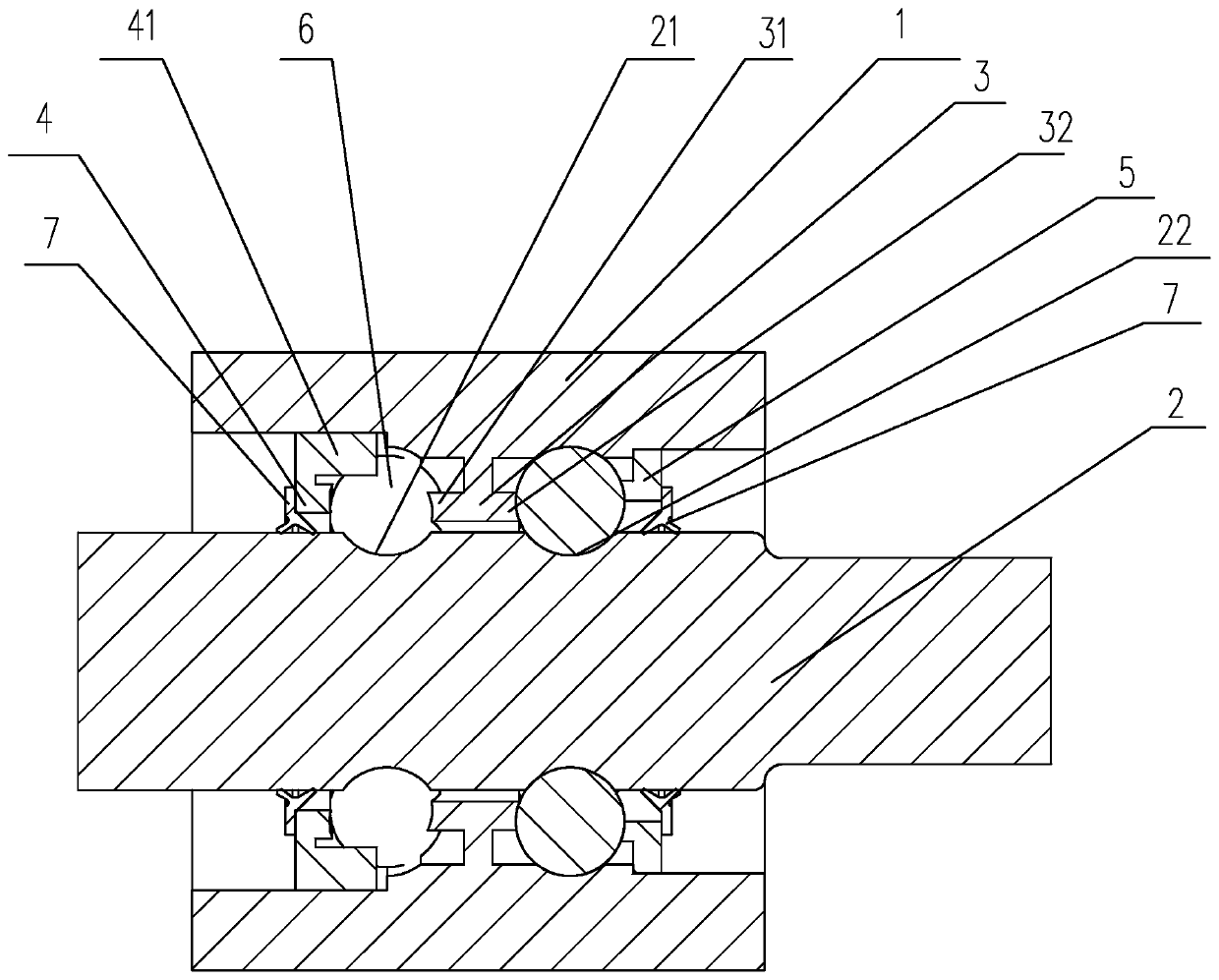

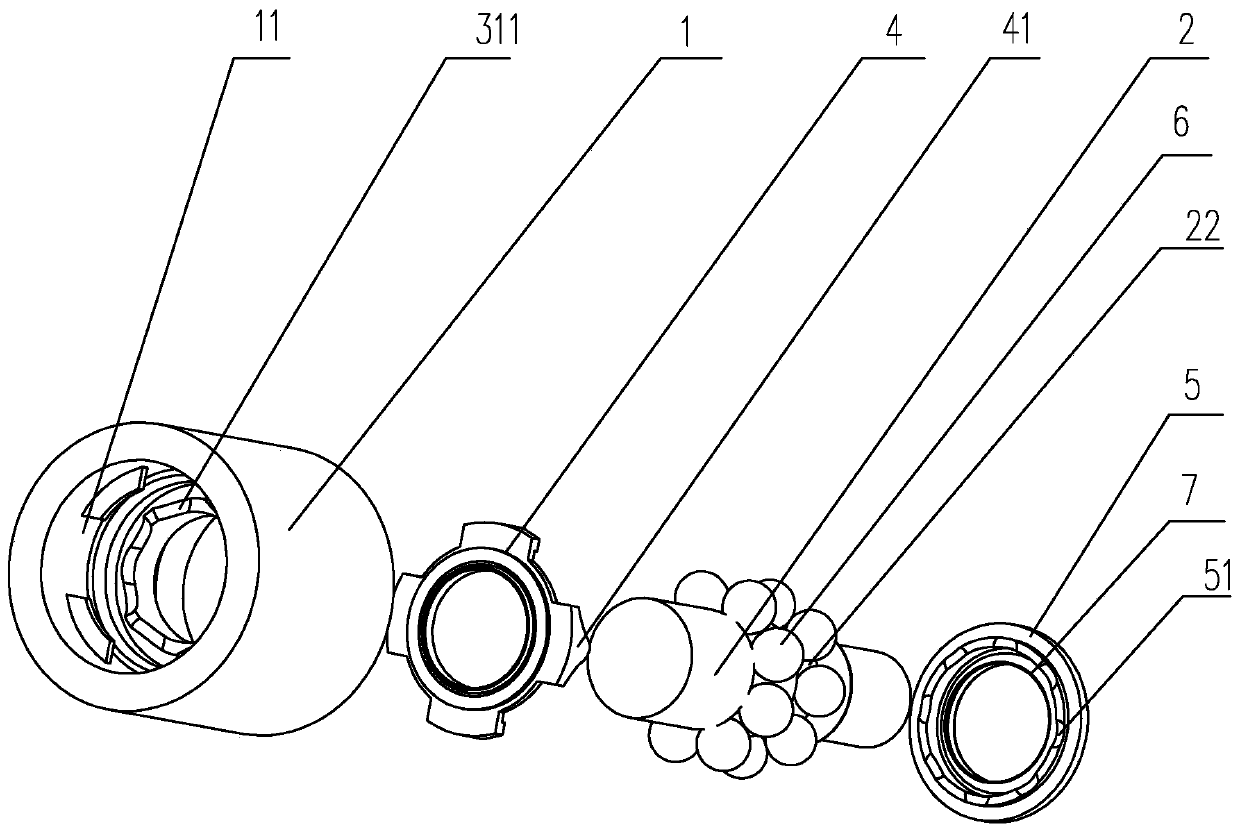

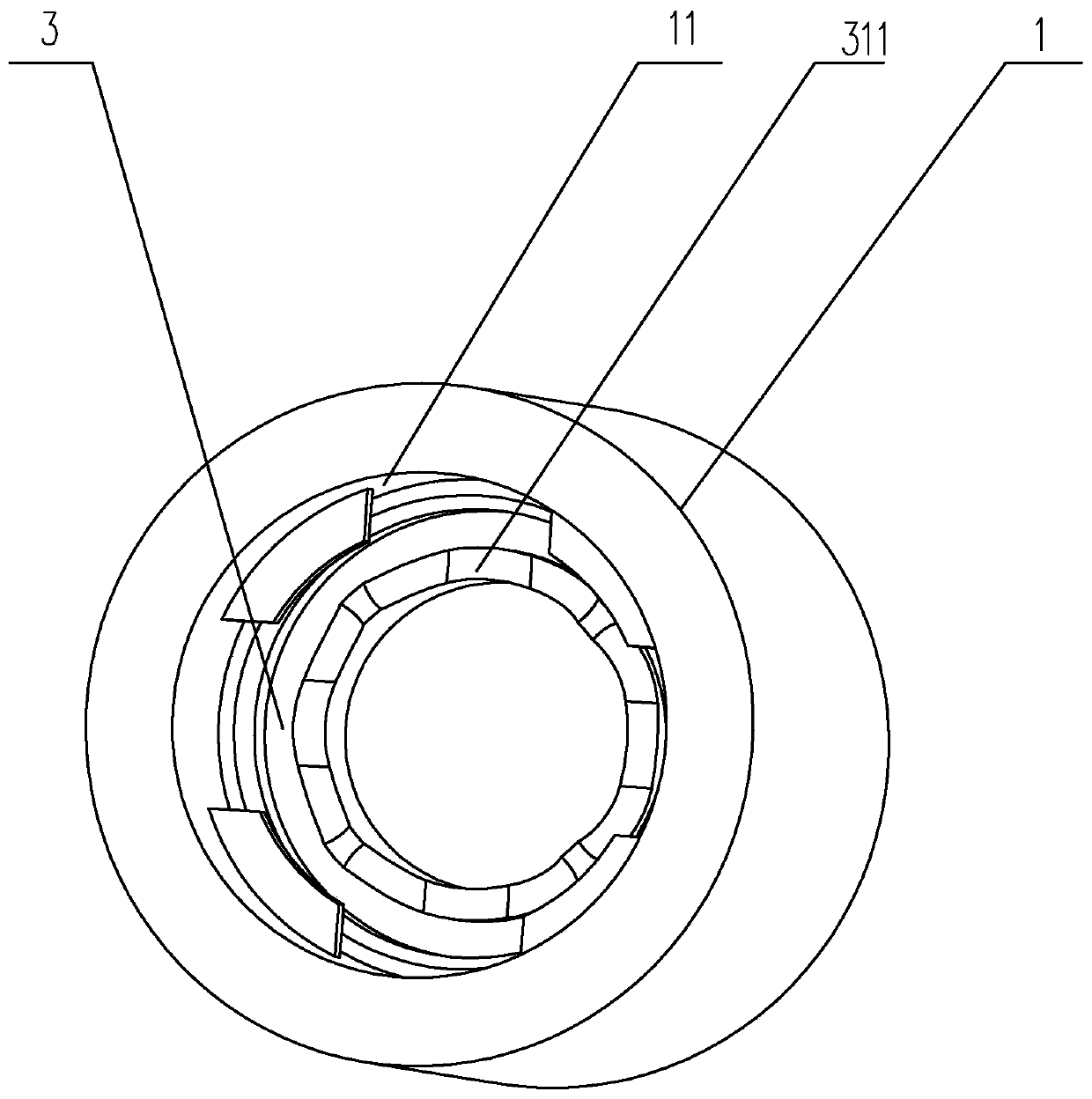

[0017] Embodiments of the shaft-connected bearing of the double-row ball water pump of the present invention are for example Figure 1-2 Shown: including the outer ring 1 and the mandrel 2, a first raceway groove 21 and a second raceway groove 22 are formed between the outer ring 1 and the mandrel 2, and the first raceway groove 21 is close to the mandrel 2 The pulley end is set, the second raceway groove 22 is set close to the impeller end, the first raceway groove 21 and the second raceway groove 22 are provided with rolling steel balls 6, and the inner wall of the outer ring 1 is on the A positioning frame 3 is arranged between the first raceway groove 21 and the second raceway groove 22. The cross section of the positioning frame 3 is T-shaped. The positioning frame 3 includes a base and first positioning protrusions arranged on both sides of the base edge 31 and a second positioning flange 32, the first positioning flange 31 is arranged close to the first raceway groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com