direct transmission assembly

A direct-type, assembly technology, applied in the field of compact racks, can solve the problems of high installation technology, low transmission efficiency, and many operating failures, and achieve the effect of low equipment technology requirements, good power transmission characteristics, and simple transmission methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

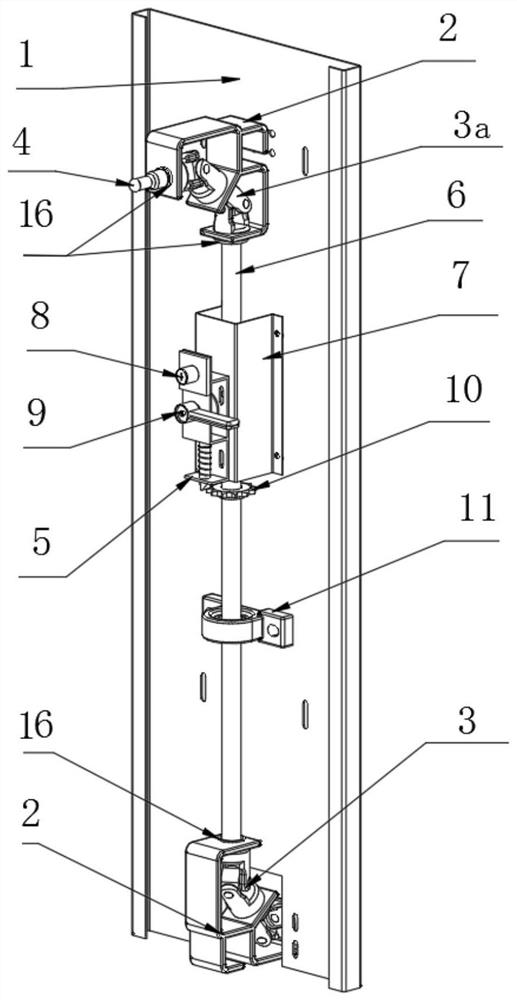

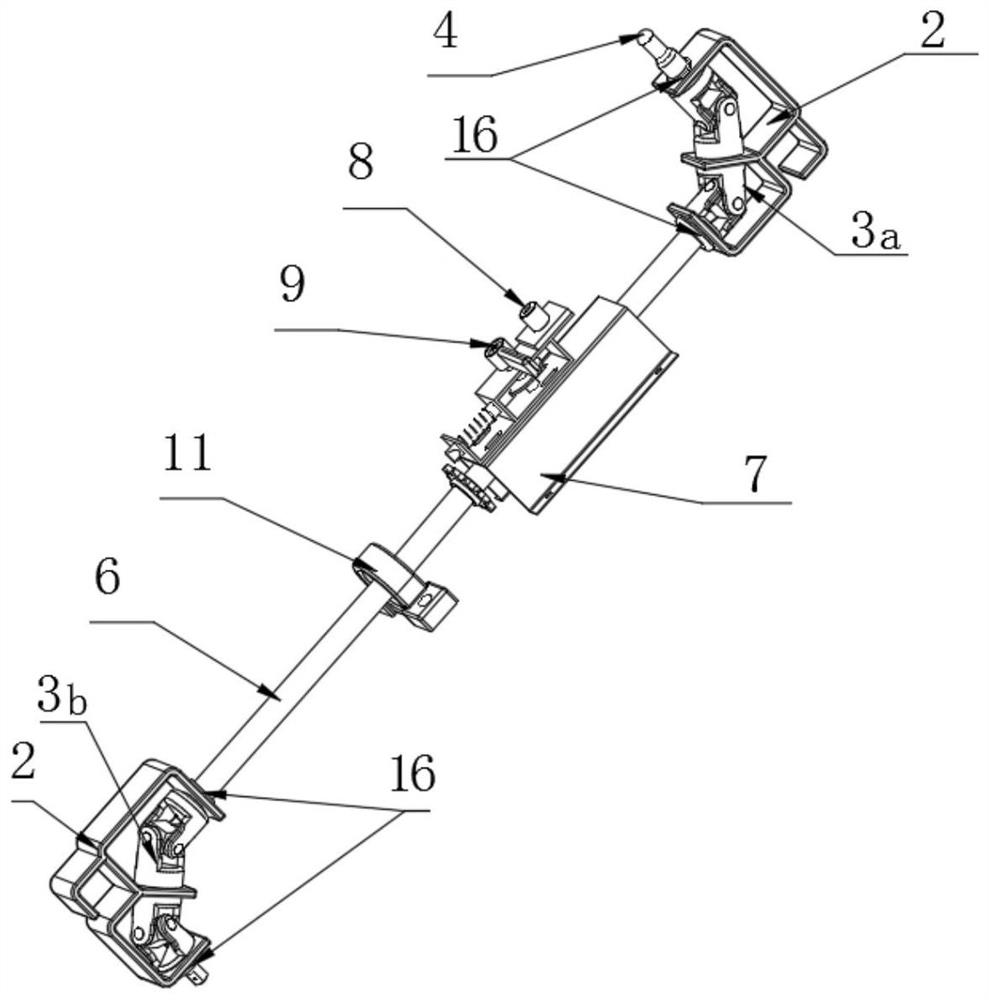

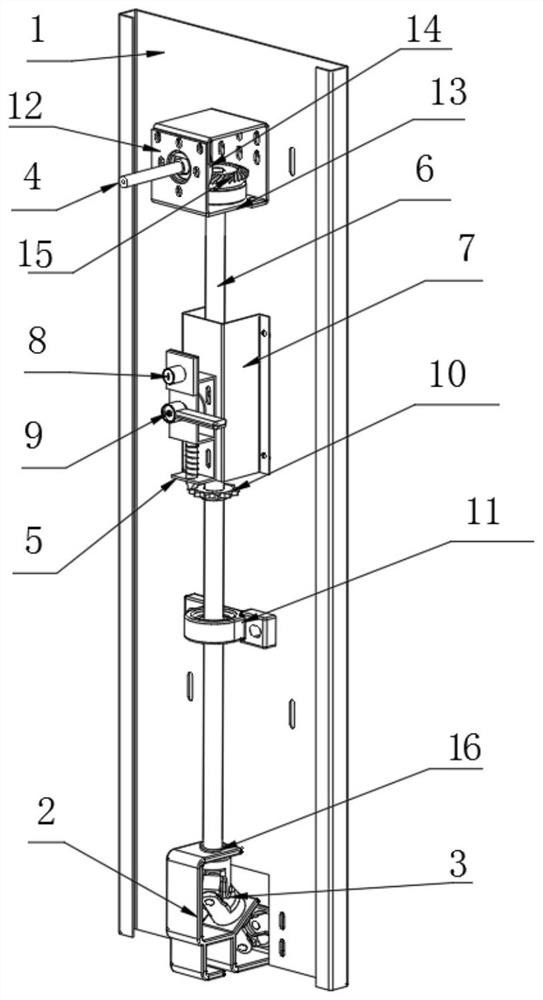

[0007] In order to further understand the technical solutions of the present invention, the present invention will be further described through the following embodiments in conjunction with the accompanying drawings. like Figure 1-2 shown. The direct-type high-efficiency and low-loss transmission assembly of the present invention includes an assembly plate 1, a transmission shaft 6, a rocker input shaft 4, a total lock 8, a brake lock 9, and the corresponding input universal joint coupling transmitter and output universal joint coupling. transmitter, etc. The cross double-section universal joint is arranged on the assembly plate through a right-angle integral 3-shaped mounting bracket and its corresponding bearing device. The gimbal-coupled transmitter includes a cross double-joint gimbal.

[0008] The input universal joint coupling transmitter and the output universal joint coupling transmitter are respectively composed of cross double-section universal joints 3 . The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com