High-precision leaked liquid detection and recovery early warning device

An early warning device, high-precision technology, applied in the measurement device, by detecting the presence of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problem of easy damage, coolant flooding, adjacent modules Damage and other problems, to achieve the effect of reducing the detection misjudgment rate, strong anti-interference ability, and high reliability early warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

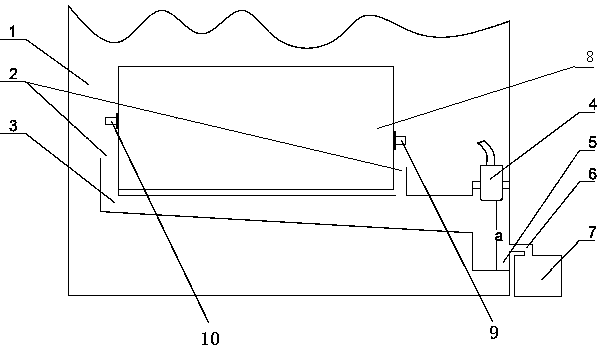

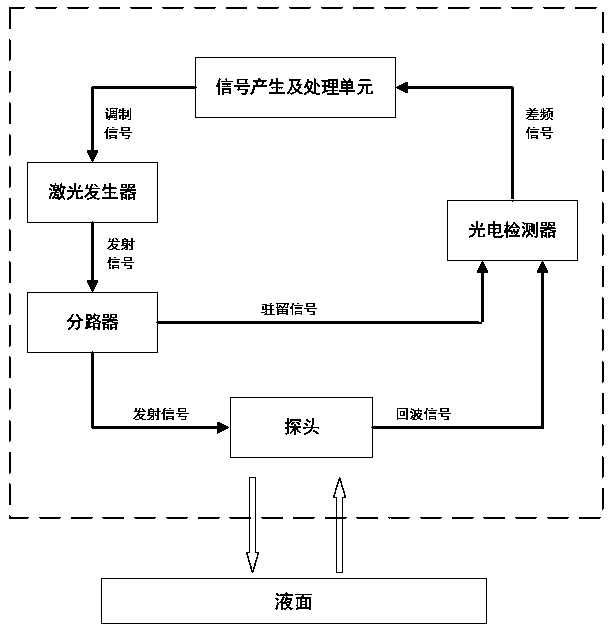

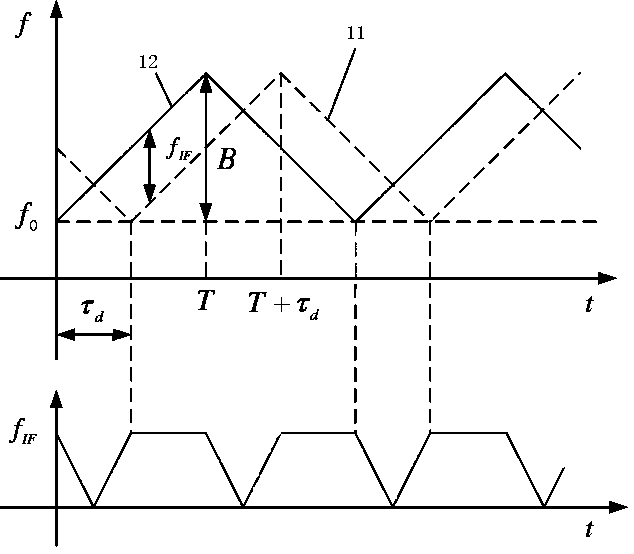

[0032] A high-precision liquid leakage detection and recovery early warning device described in this embodiment, such as figure 1 As shown, it includes a leakage confluence port 2, a leakage confluence channel 3, a chirp laser ranging sensor 4, a leakage collection tank 5, a leakage recovery joint 6, a leakage recovery storage tank 7, and the leakage confluence 2 It communicates with the leakage confluence channel 3, the leakage collection tank 5 communicates with the leakage confluence channel 3, and a linear frequency modulation laser ranging sensor 4 is fixed above the leakage collection tank 5, and the leakage The recovery storage tank 7 communicates with the leaked liquid collection tank 5 through the leaked liquid recovery joint 6, figure 1 It also includes an equipment case, a cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com