Inner container structure of dish-washing machine

A dishwasher liner and liner technology, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, household cleaning devices, etc., can solve poor sealing effects, easy accumulation of dirt, Reduce the service life of the sealing frame and other issues to achieve the effects of increasing the service life, avoiding the erosion of the sealing structure, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

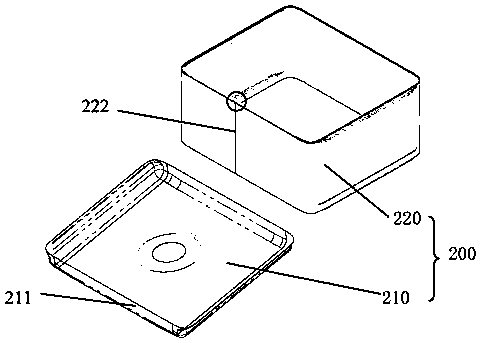

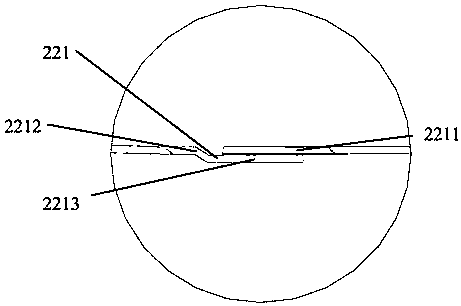

[0046] Such as figure 1 with figure 2 As shown, the present embodiment includes an inner tank bottom 210 and an inner tank side part 220, the inner tank bottom 210 and the inner tank side part 220 form an inner tank main body 200 with an upward opening, and the inner tank side part 220 is a plate The piece is rolled into a ring by bending. One end of the plate has a splicing part 221, and the other end is overlapped on the splicing part 221. The splicing positions 222 at both ends are located on the plane, which eliminates the influence of dimensional errors on the assembly structure and is convenient for determining the final The size of the splicing parts is welded, the weld seam is regular, and the welding plane treatment process is simple, which improves the production efficiency of the dishwasher.

[0047] Such as figure 2 As shown, the splicing part 221 is a bent structure formed by bending one end of the plate, and the end of the bent structure is kept parallel to t...

Embodiment 2

[0074] Such as Figure 8 As shown, the main body 200 of the dishwasher liner in this embodiment is composed of three splicing parts, including a first splicing part, a second splicing part and a third splicing part, and the second splicing part and the third splicing part are located at the first Both sides of a splicing part are parallel to the stretching direction of the dishwasher, and the splicing positions of the second splicing part / third splicing part and the first splicing part are located on a plane.

[0075] The first splicing part includes a bottom plate 204 of the main body of the liner and a front plate 201 and a rear plate 202 connected to the bottom plate 204 and perpendicular to the stretching direction of the dishwasher.

[0076] The second splicing part / third splicing part includes a side plate 203 parallel to the stretching direction of the dishwasher, and the second splicing part / third splicing part also includes a A bent extension part, the extension part...

Embodiment 3

[0093] Such as Figure 10 As shown, the difference between the structure of the liner main body 200 in this embodiment and the first embodiment is that at least one of the two ends at the splicing position 222 is provided with a notch. The notch is used to place the detergent adding device. Installation port 2011.

[0094] Such as Figure 10 As shown, this embodiment provides an inner container structure applied in a drawer dishwasher, including an inner container main body 200, which is formed by enclosing an inner container bottom 210 and an inner container side part 220, and the inner container The side part 220 includes a first splicing portion 2012 and a second splicing portion 2013, the first splicing portion 2012 and the second splicing portion 2013 are spliced to form a side wall, and the first splicing portion 2012 and / or the second splicing portion 2013 is provided with a gap After the first splicing part 2012 and the second splicing part 2013 are spliced, the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com