Isolation air exchange mechanism based on medical protection device in infectious disease treatment process

A disease treatment and protective device technology, applied in protective devices against harmful chemicals, thermal insulation protective devices, protective clothing, etc. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, when the medical personnel need to ventilate the gas inside the protective clothing 17, they enter the isolation room 1 by opening the hatch 16, then close the hatch 16, and connect the ventilating port 19 with the ventilating joint 22 Rotate the docking to make the internal thread 26 and the external thread 27 threaded. At this time, the front end of the insertion rod 30 squeezes the internal thread 26 and pushes the internal thread 26 to the rear side. At this time, the internal thread 26 and the inner side of the ventilation port 19 are tightly After the bonding is released, the medical staff can discharge the air in the inner compartment of the protective clothing 17 through the passage formed by the ventilation joint 22 and the ventilation port 19, and then exhaust it through the exhaust port 24. When the hot air inside the protective clothing 17 is discharged, the medical staff can Personnel can remove the ventilation joint 22 on the air outlet pipe 2...

Embodiment 2

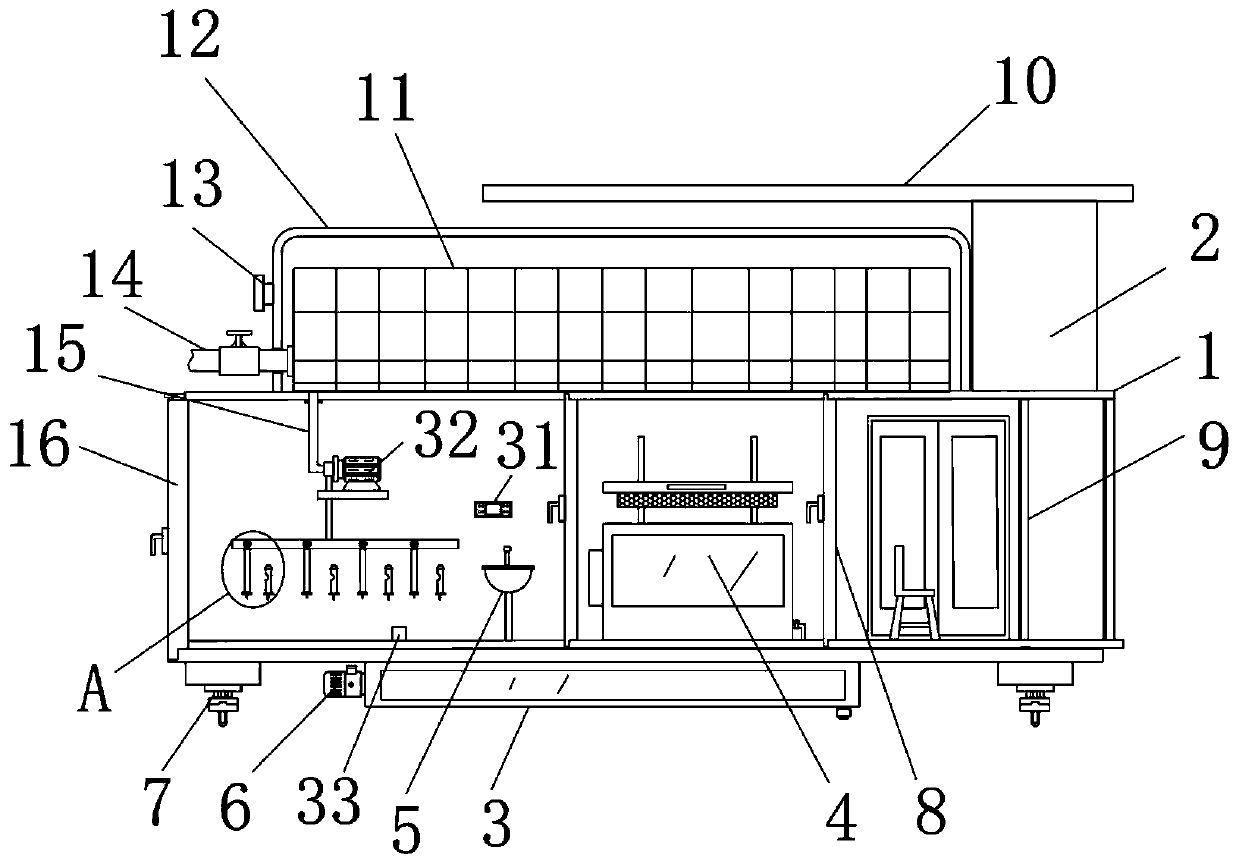

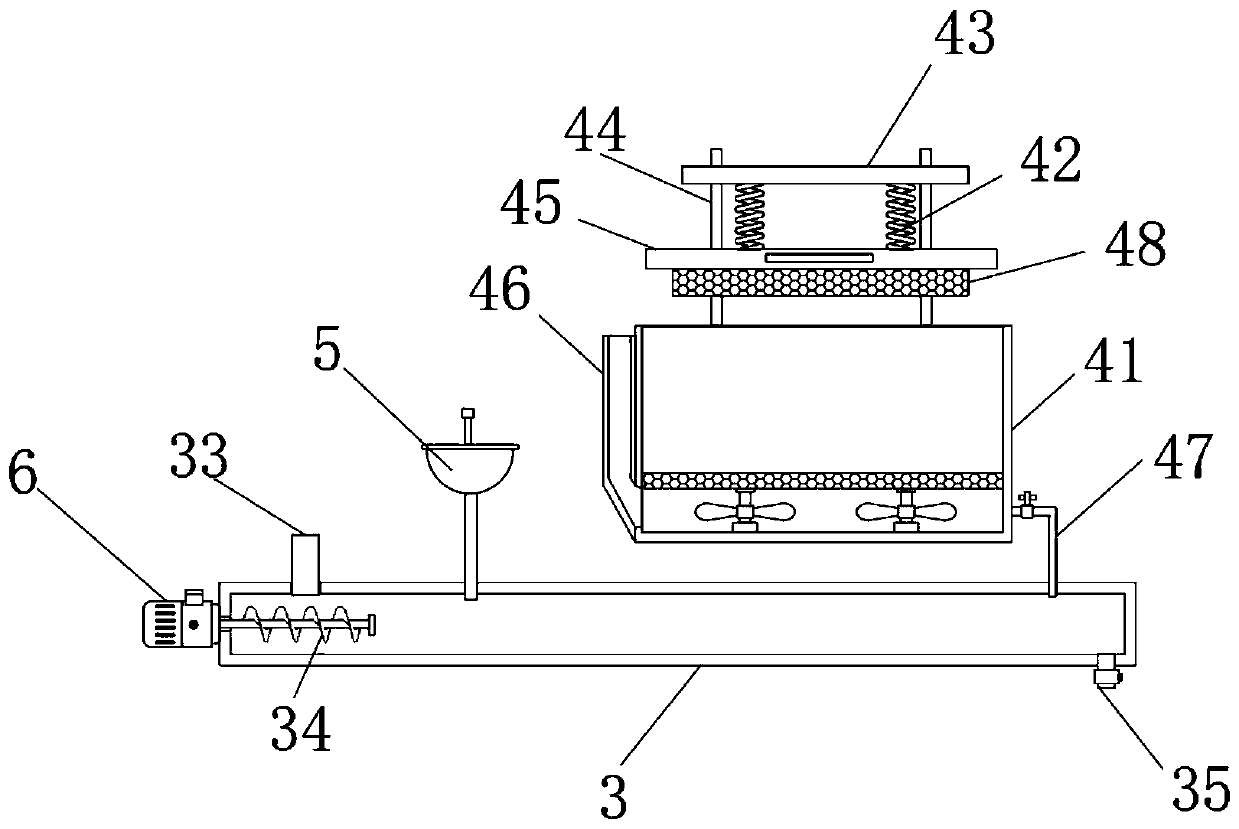

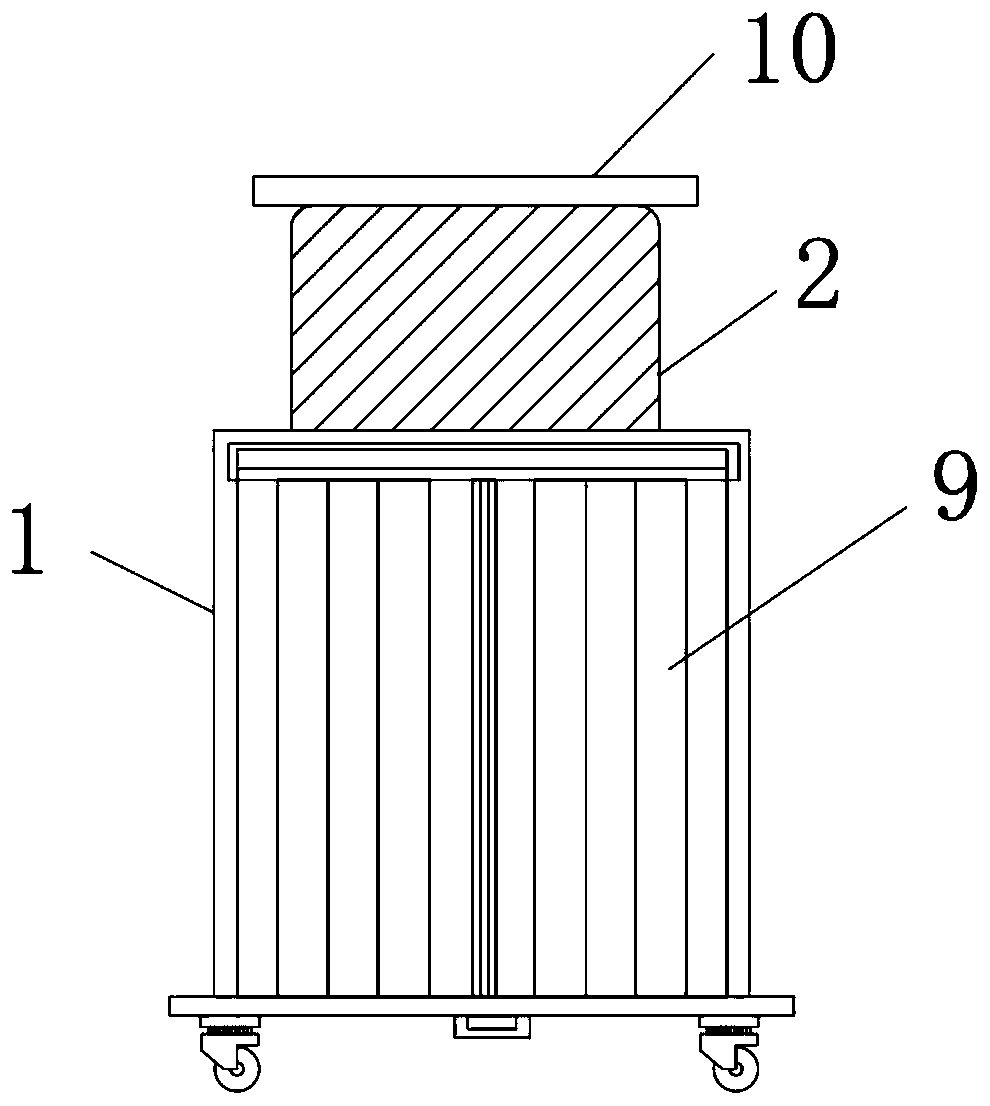

[0033] Embodiment two, see appendix figure 1 , attached figure 2 And attached Figure 6 , when the medical personnel need to replace the protective clothing 17, they take off their gloves at the sink 5 and clean their hands, and then remove the protective clothing 17 according to medical guidelines. After completing the removal work, open the first interval door 8, then push the disinfection cover 45 upwards, then place the changed protective clothing 17 inside the disinfection tank 41, then loosen the disinfection cover 45, and the elastic force produced by the return spring 42 after being squeezed will close the disinfection cover. Body 45 bounces back, and extruding net 48 has played the effect of compressing, and avoids that protective clothing 17 floats up, and will be added in the disinfection tank 41 through the liquid filling port 46 places for the disinfectant liquid of this kind of infectious disease afterwards, and can pass through control The panel 31 starts the...

Embodiment 3

[0035] Embodiment three, see appendix figure 1 And attached figure 2 The sewage used by the medical staff to wash their hands and clean the protective clothing 17 can flow into the waste water tank 3 for storage, and the medical staff can add the medicinal solution for disinfecting the infectious disease medical sewage through the dosing port 33 and then start the motor through the control panel 31 6. The motor 6 drives the stirring rod 34 to rotate to accelerate the fusion of the liquid medicine and the sewage, and the medical sewage is discharged by opening the second drain pipe 35 at least 6 hours after the liquid medicine is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com