Full-automatic glue dispenser

A dispensing machine, fully automatic technology, applied in the direction of coating, coating liquid on the surface, etc., can solve the problems of reducing the working efficiency of the dispensing machine and consuming large human resources, so as to improve the contact fixing effect and reduce manpower Consumption of resources, effect of improving clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

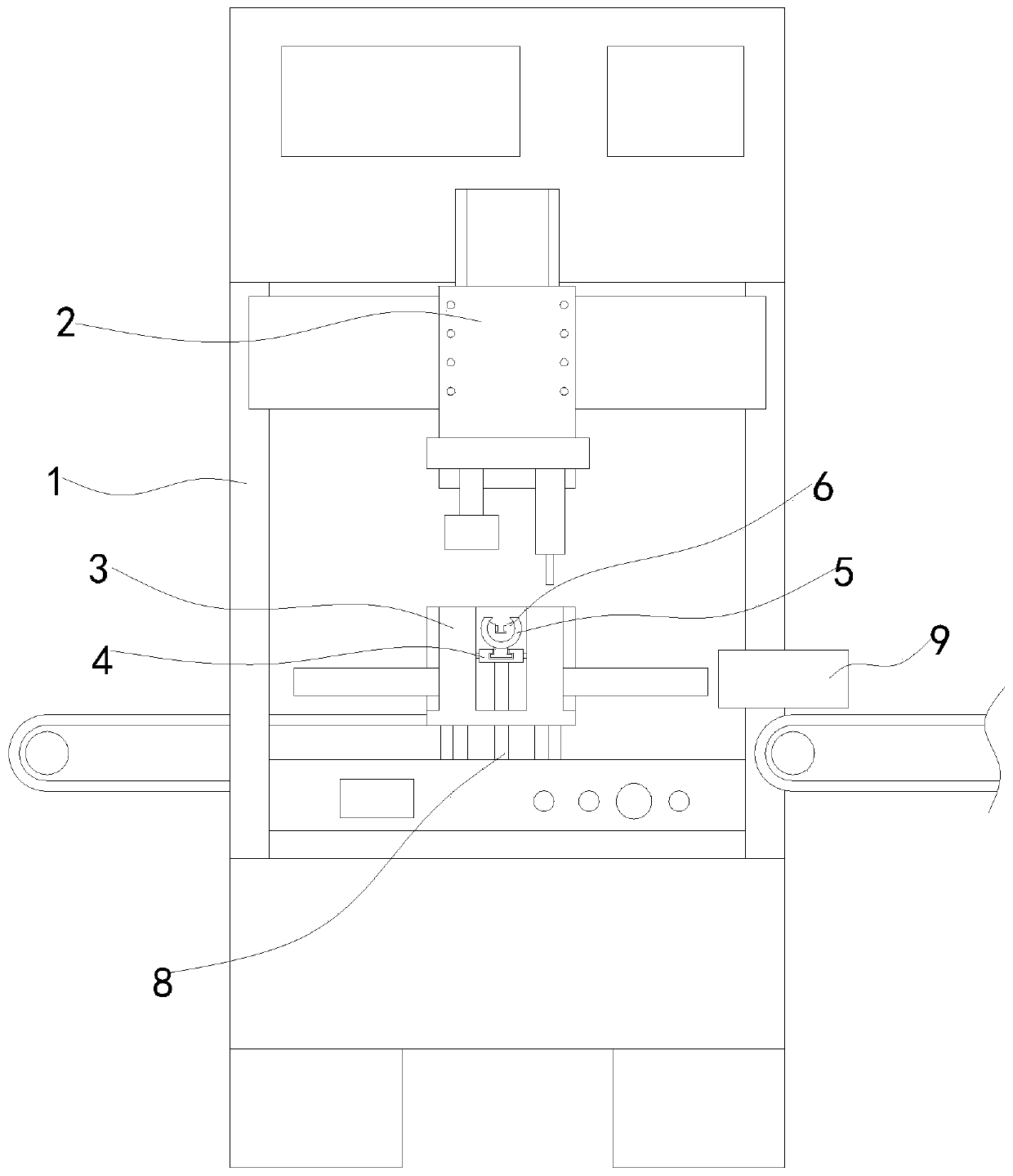

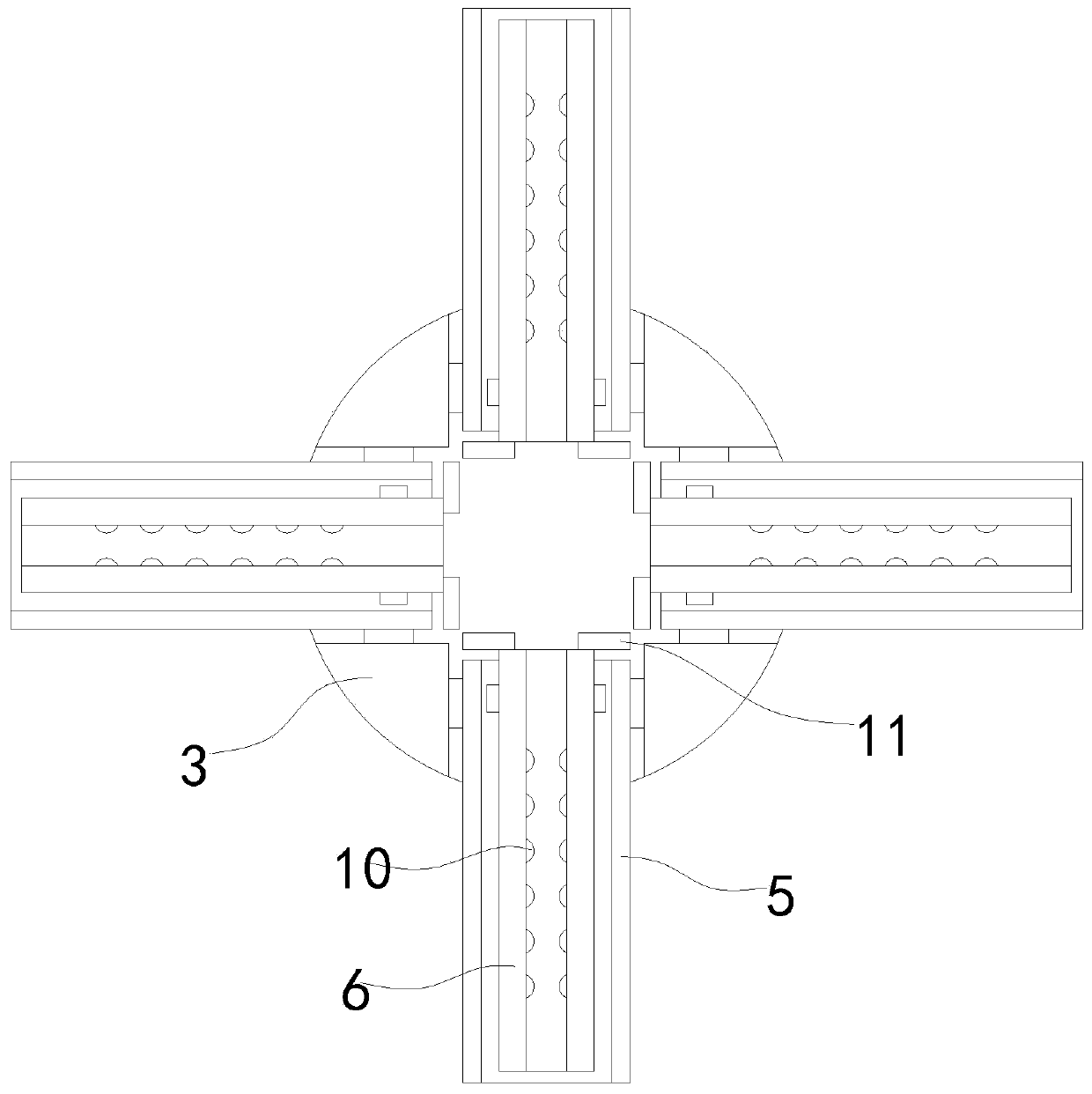

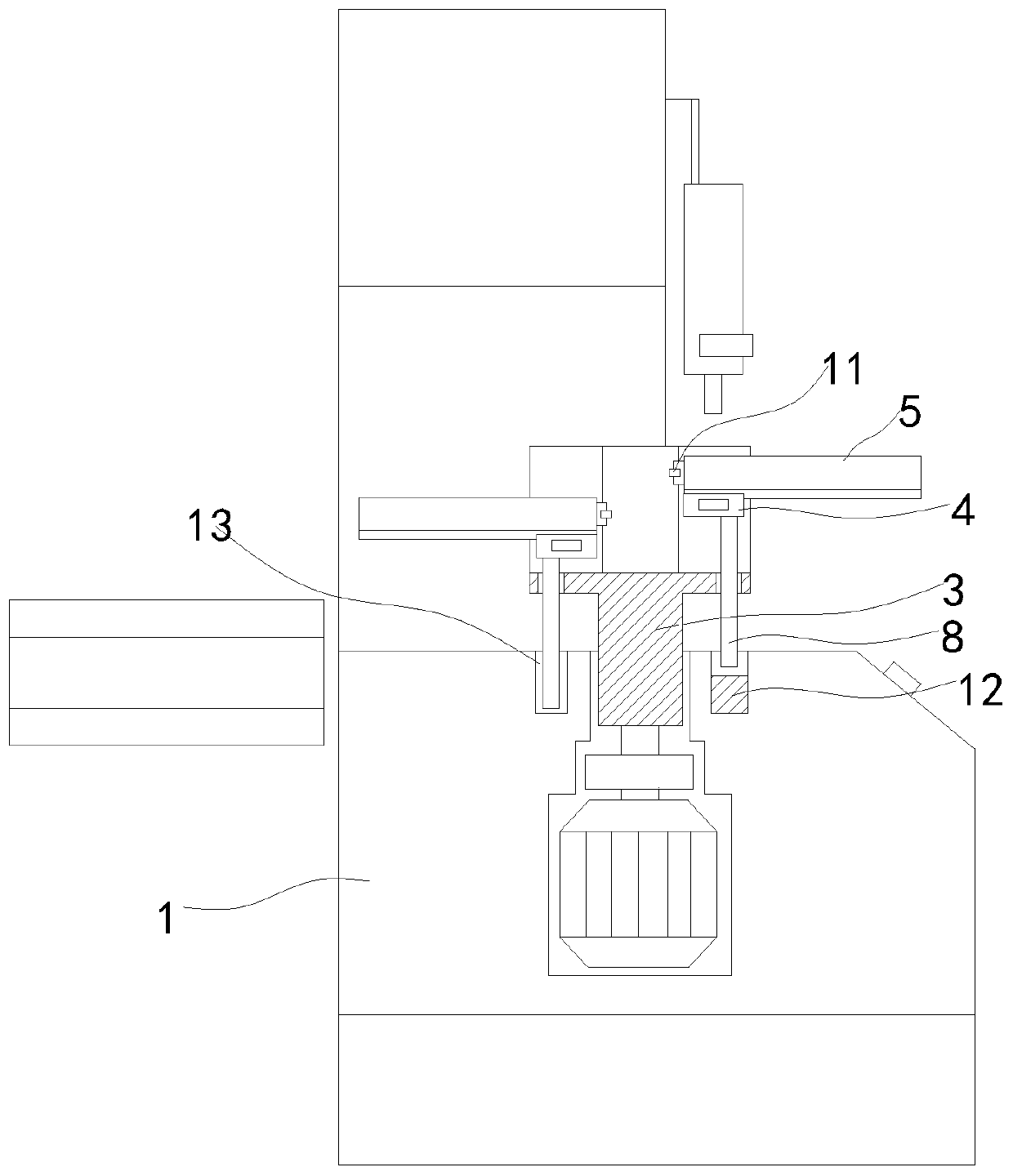

[0026] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a fully automatic dispensing machine.

[0027] A fully automatic dispensing machine, comprising a device main body 1, a workpiece rotating table 3 is movably installed at the lower end of the device main body 1, an inner moving rod 5 is movably installed inside the workpiece rotating table 3, and a baffle plate 9 is fixedly installed on the right side of the device main body 1 , The workpiece guide plate 7 is fixedly installed at the rear end of the baffle plate 9 .

[0028] In the specific implementation, the workpiece holder 6 is movably installed inside the moving rod 5, the clamping block 10 is movably installed inside the workpiece holder 6, and the dispensing device 2 is movably installed on the upper end of the device main body 1, so that the required While the workpiece being processed is put into the workpiece holder 6 and fixed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com