Submerged nozzle and use method thereof

An immersion and nozzle technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of reducing slag in conventional slab continuous casting, eliminating dead zones, and immersion nozzles cannot be realized at the same time. The effect of reducing the dead zone of the mold, reducing the occurrence of slag and eliminating the dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

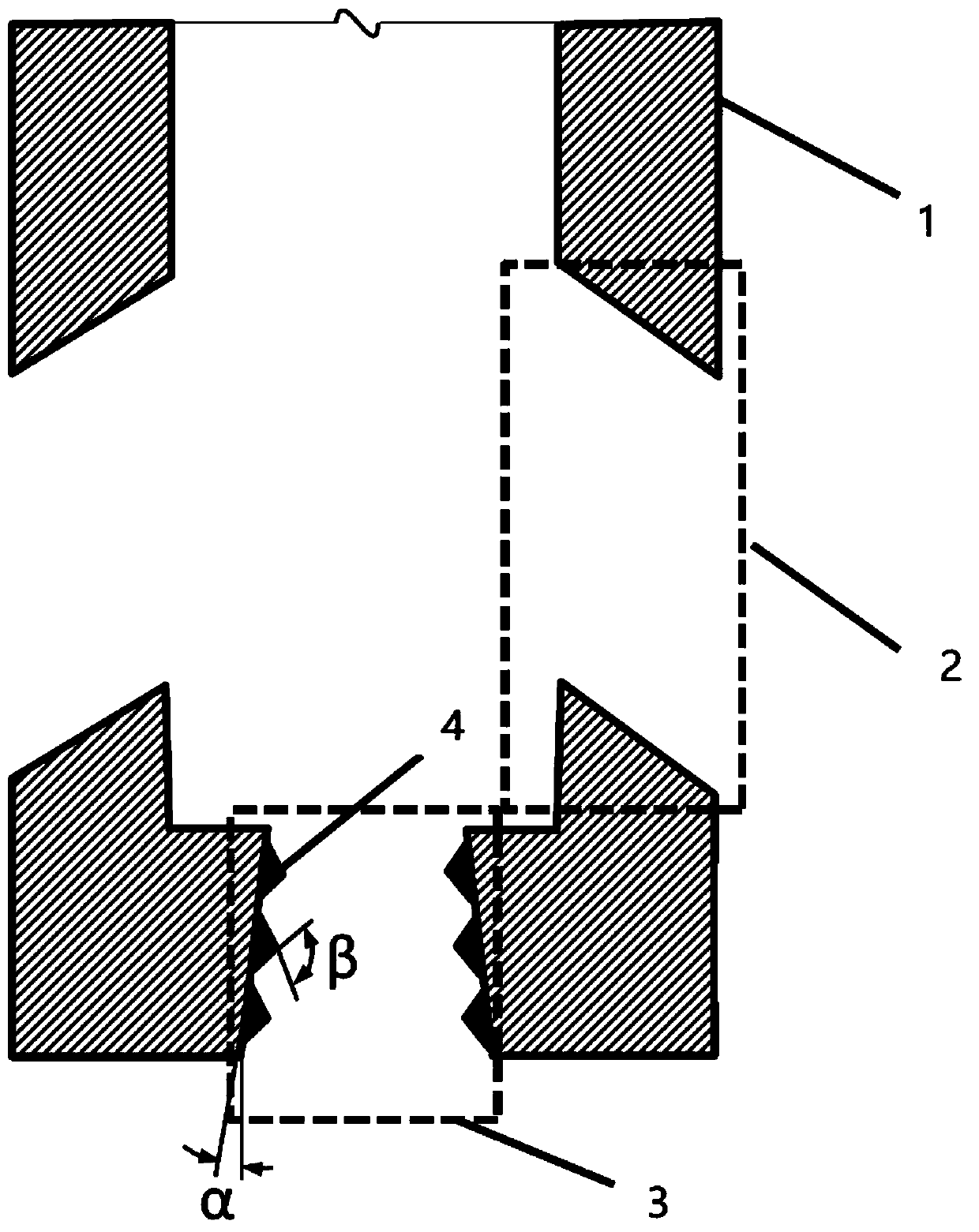

[0017] see figure 1 , the embodiment of the present invention provides a submerged nozzle comprising: nozzle body 1 .

[0018] A nozzle outlet hole 2 is opened on the side wall of the nozzle body 1 .

[0019] A bottom hole 3 is opened at the bottom of the nozzle body 1 .

[0020] Several circles of bosses 4 are fixedly arranged in the bottom hole 3 .

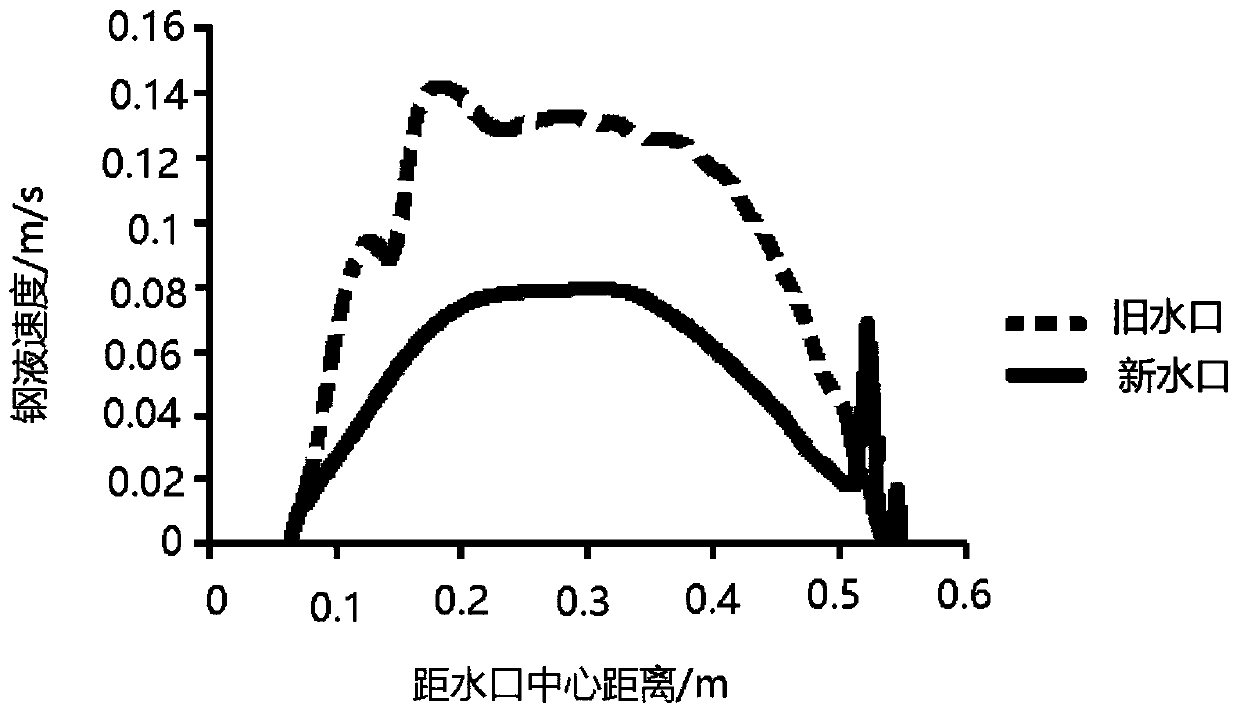

[0021] Specific embodiments of the present application Since the side wall of the nozzle body is provided with a nozzle outlet hole, and the bottom of the nozzle body is provided with a bottom hole, so the bottom hole has a diversion effect, which can reduce the flow rate of molten steel at the outlet of the bottom hole, and the crystallizer liquid The surface velocity is significantly reduced, which is beneficial to reduce the occurrence of slag entrainment. Due to the diversion effect of the bottom hole, fresh molten steel enters the bottom of the nozzle body, which can effectively reduce the dead zone of the crystallizer an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com