Fixture for polishing of outer circular surface of jade bracelet

A technology of external circular surface and jade bracelet, which is applied in the direction of grinding frame, grinding bed, grinding sliding plate, etc., can solve the problems of different sizes and affect processing efficiency, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

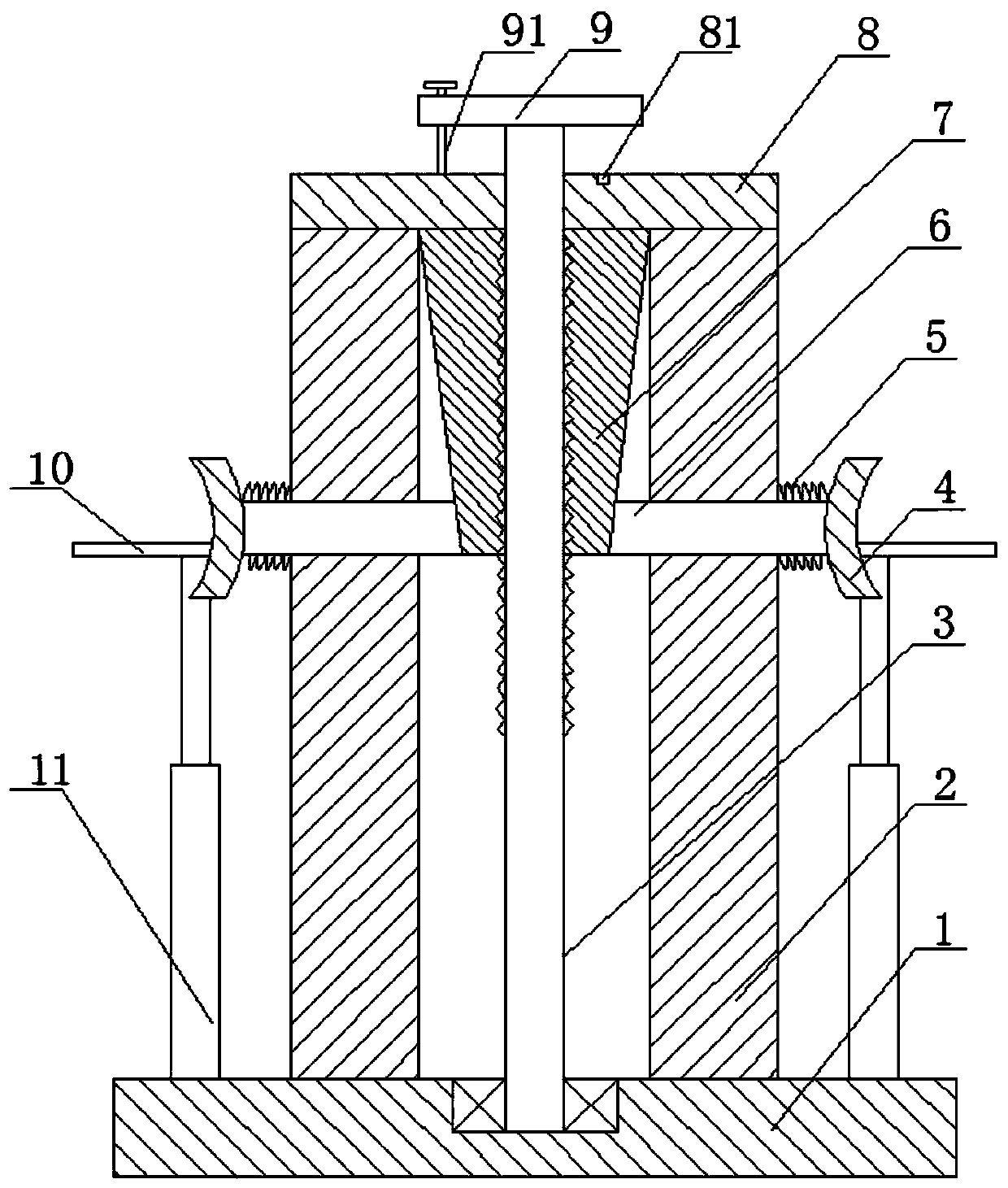

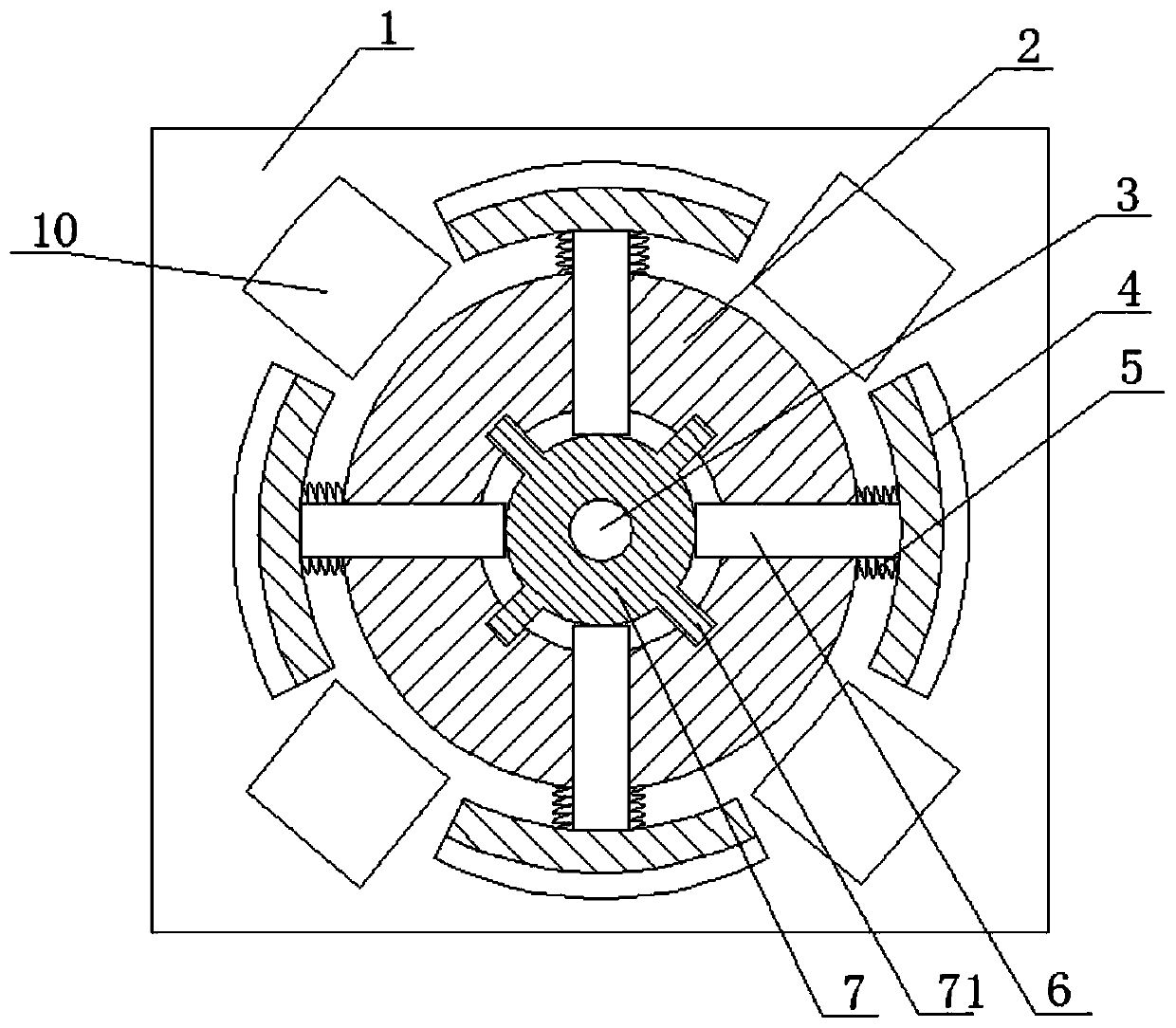

[0036] Embodiments of the present invention provide a jig for polishing the outer surface of a jade bracelet, such as Figure 1 to Figure 2 As shown, it includes: a support plate 1, which is detachably connected to the workbench; a cylinder body 2, which is vertically arranged on the top of the support plate 1; Inside the body 2; the slider 7 has a trapezoidal cross-section, and is set on the screw 3 with four limiting platforms 71, which are evenly distributed in the circumferential direction of the slider 7; 2 The direction of the center line is evenly distributed on the inner wall of the cylinder 2; four guide holes are evenly distributed on the circumference of the cylinder 2 and communicated with the cylinder 2, the centerline of the guide hole is perpendicular to the centerline of the cylinder 2; the support The structure is arranged in the guide hole, including: a support rod 6 pierced in the guide hole; an arc-shaped support part 4 is arranged at the end of the support...

Embodiment 2

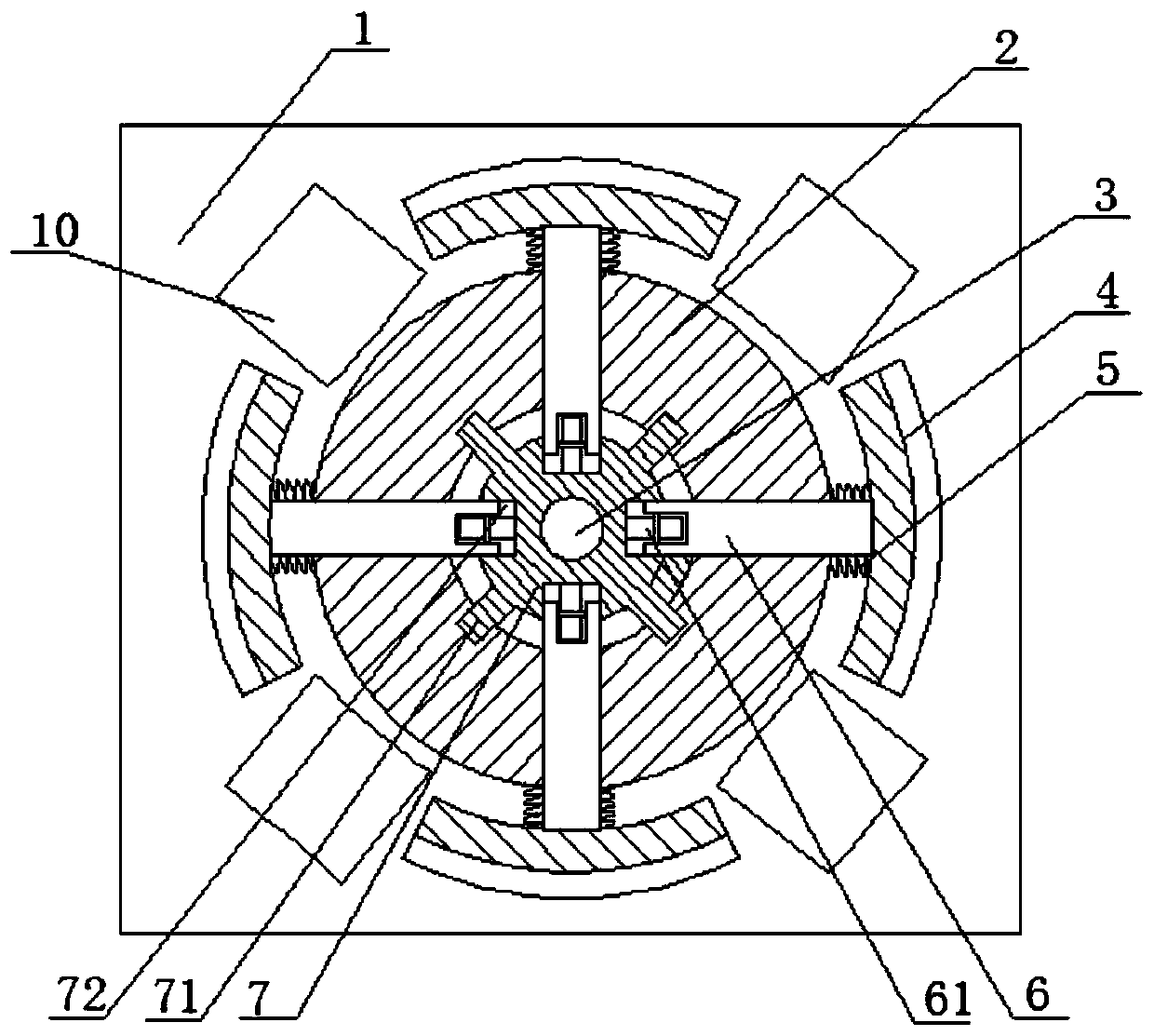

[0040] On the basis of Example 1, further, such as image 3 As shown, the end of the support rod 6 close to the slider 7 is provided with a roller 61 , and the roller 61 can roll in the guide groove 72 .

[0041] Further, a rubber layer is arranged in the receiving groove on the supporting part 4 .

[0042] Further, a limiting plate 8 is detachably connected to the top of the cylinder body 2 , and the limiting plate 8 is sleeved on the screw rod 3 .

[0043] Further, a handle 9 is provided on the top of the screw rod 3 , and a limiting structure for limiting rotation of the handle is provided between the handle 9 and the limiting plate 8 .

[0044] Further, the limiting structure includes a plurality of limiting holes I81 evenly distributed around the screw rod 3 on the limiting plate 8 and corresponding limiting holes II on the handle 9, and limiting holes II and I81 are perforated with limiting holes. pin 91.

[0045] Further, a plurality of vertically arranged telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com