Water-based epoxy hybrid acrylic self-crosslinking quick-drying coating used in high humidity environment and preparation method thereof

A quick-drying coating and high-humidity technology, applied to anti-corrosion coatings, coatings, etc., can solve the problems of easy sagging, poor adhesion, and emulsion film formation, etc., and achieve the best initial water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

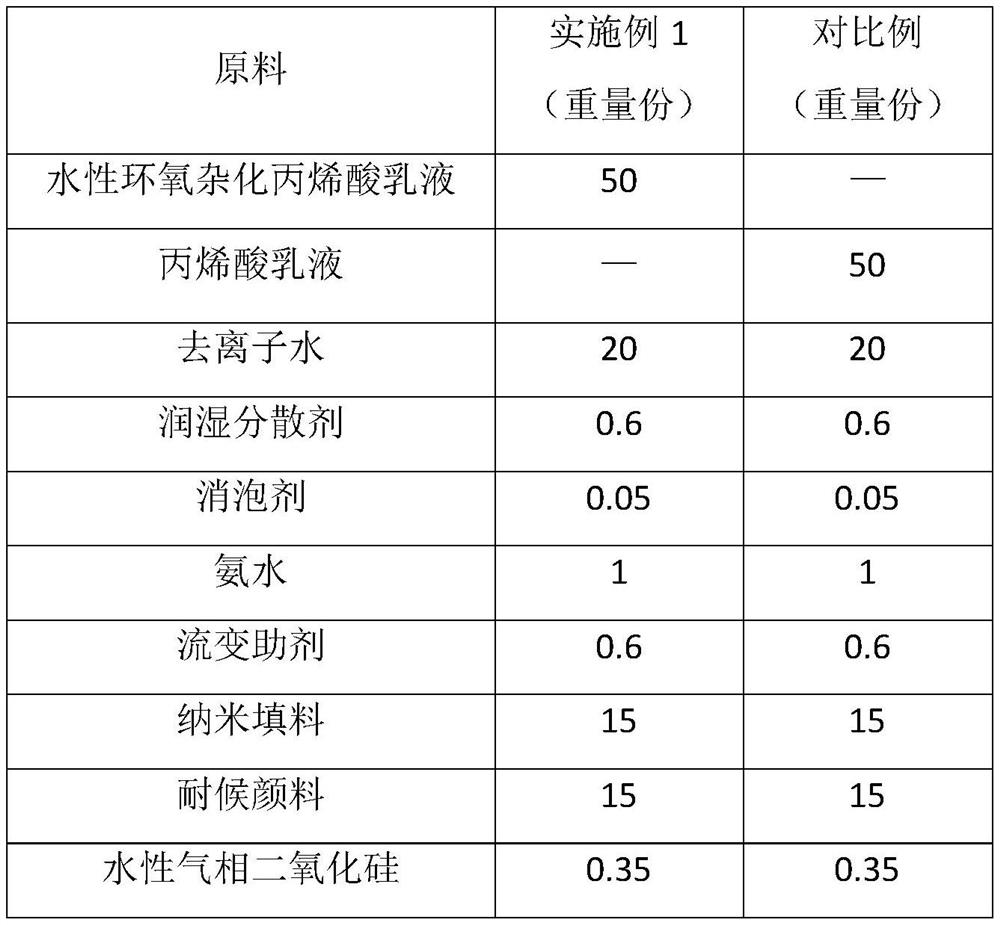

Embodiment 1

[0039] The water-based epoxy hybrid acrylic emulsion of the present embodiment is prepared through the following steps:

[0040] (1) Preparation of water-based epoxy hybrid acrylic emulsion

[0041] a. Preparation of epoxy acrylate resin EA:

[0042] Add 68% E-51, 12% acrylic acid, and 0.5% triethylbenzyl ammonium chloride into four three-necked flasks, and react at 80°C for 4 hours. When the acid value is less than 5, raise the temperature to 30-40°C, add 19.5% MMA, just mix well.

[0043] b. Preparation of pre-emulsion

[0044] Disperse 1wt% emulsifier and 10wt% distilled water evenly, then add 50wt% methyl methacrylate, 20wt% butyl acrylate, 10wt% styrene, 5wt% diacetone acrylamide, 3.8wt% epoxy acrylate resin and 0.2 Wt% alcohol ester twelve, stirred at room temperature until fully emulsified, then added 3 / 4 initiator aqueous solution to disperse evenly to obtain a pre-emulsion;

[0045] c. Synthesis

[0046] Mix and stir 0.75wt% emulsifier, 0.25wt% alcohol ester dode...

Embodiment 2

[0053] The difference between this embodiment and Example 1 is that it is used for the water-based epoxy hybrid acrylic self-crosslinking quick-drying coating in a high-humidity environment, including: by weight, 55 parts of water-based epoxy hybrid acrylic emulsion, 25 parts of ionized water, 0.7 parts of wetting and dispersing agent, 0.08 parts of defoamer, 0.5 parts of ammonia water, 0.7 parts of rheological additives, 20 parts of nano fillers, 20 parts of weather-resistant pigments and 0.4 parts of hydrophilic fumed silica.

Embodiment 3

[0055] The difference between this embodiment and Example 1 is that it is used for the water-based epoxy hybrid acrylic self-crosslinking quick-drying coating in a high-humidity environment, including: by weight, 45 parts of water-based epoxy hybrid acrylic emulsion, 15 parts of ionized water, 0.5 parts of wetting and dispersing agent, 0.05 parts of defoamer, 0.3 parts of ammonia water, 0.5 parts of rheological modifier, 10 parts of nano filler, 8 parts of weather-resistant pigment and 0.3 part of hydrophilic fumed silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com