Twisting device and twisting machine using twisting device

A technology of twisting device and twisting machine, which is applied in the direction of continuous winding spinning machine, spinning machine, textile and paper making, etc., can solve the problems of economic benefits and energy saving, and avoid high prices. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below by using a specific typical embodiment in combination with the contents of the aforementioned "Background", "Summary of the Invention" and "Brief Description of the Drawings".

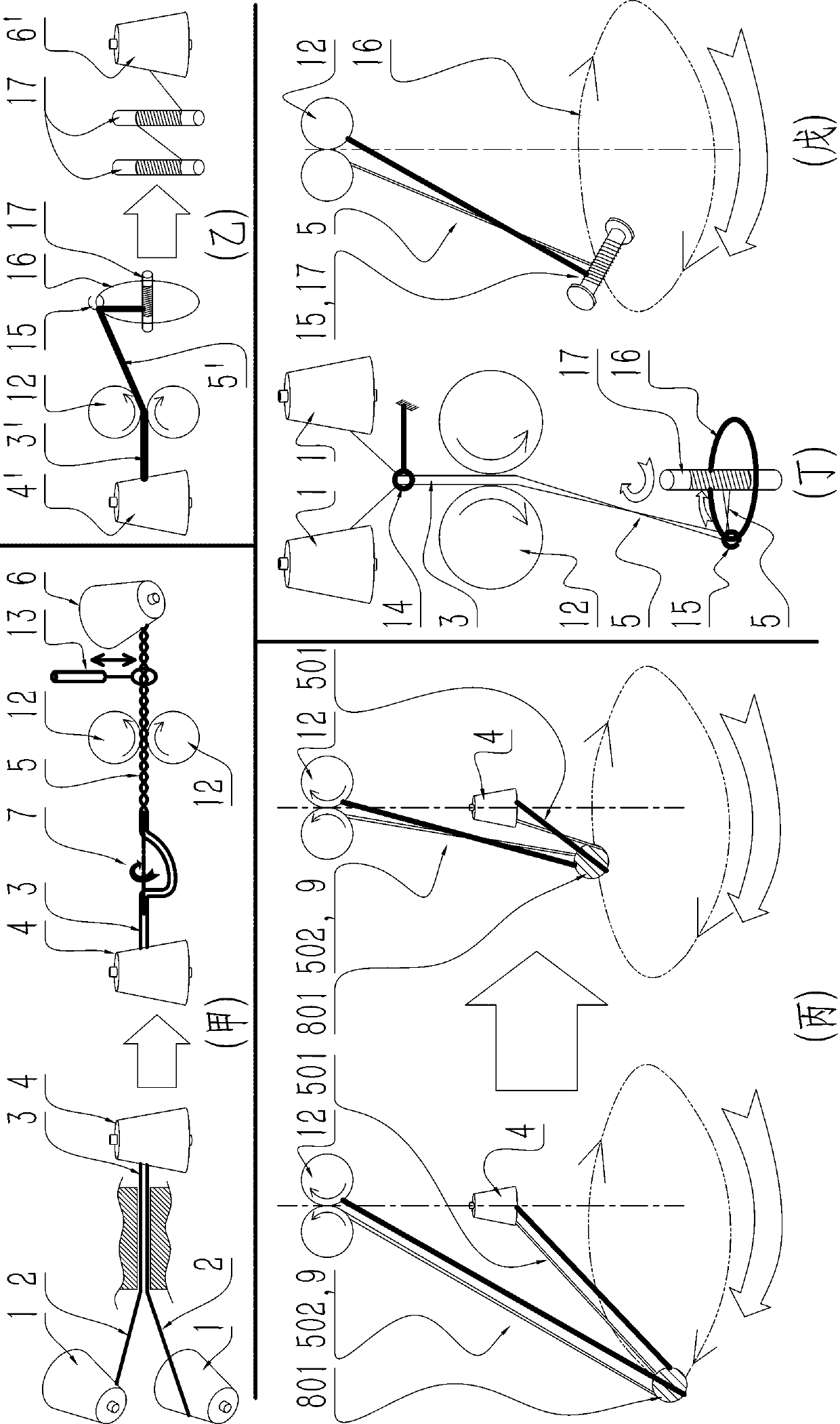

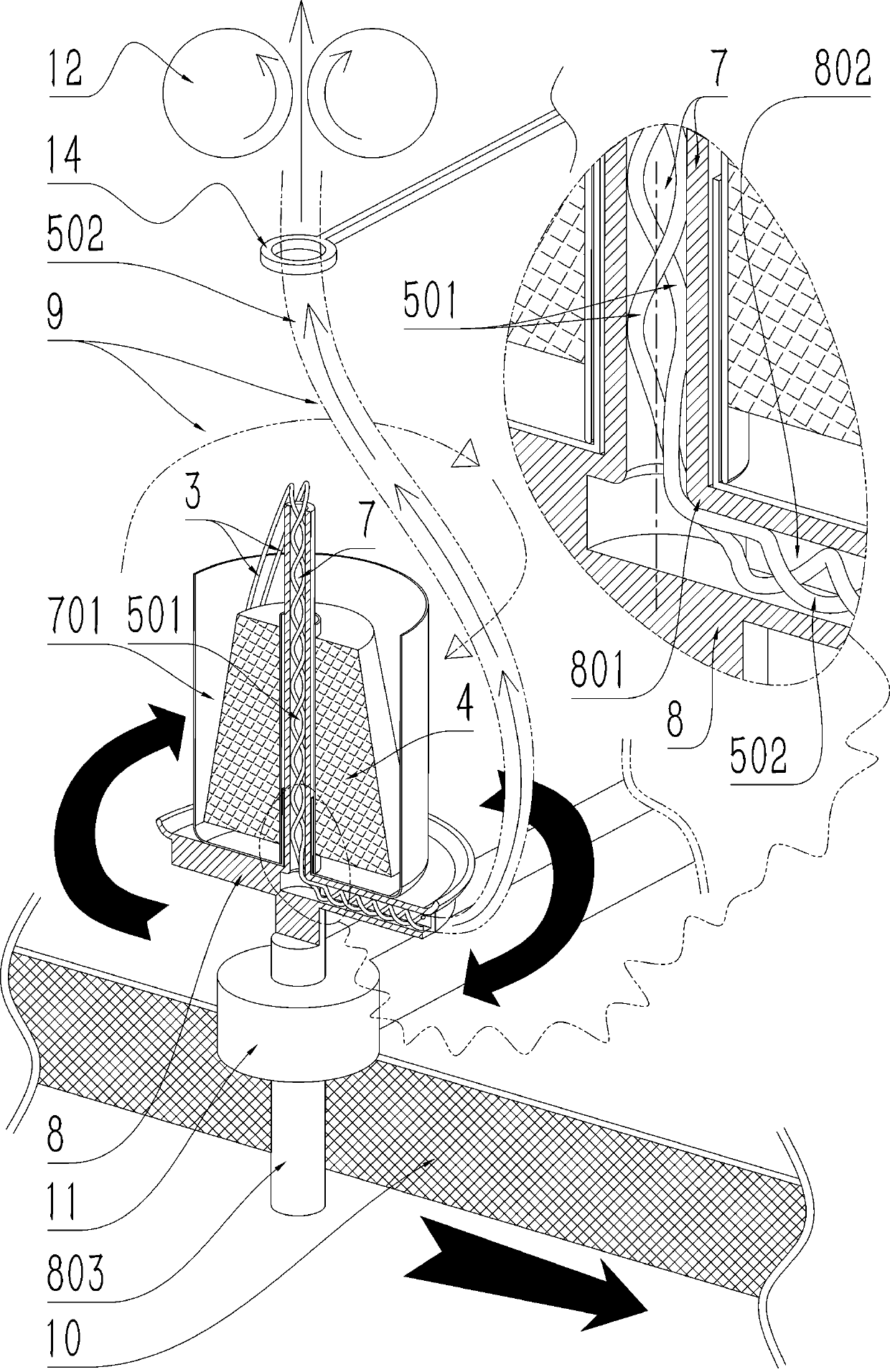

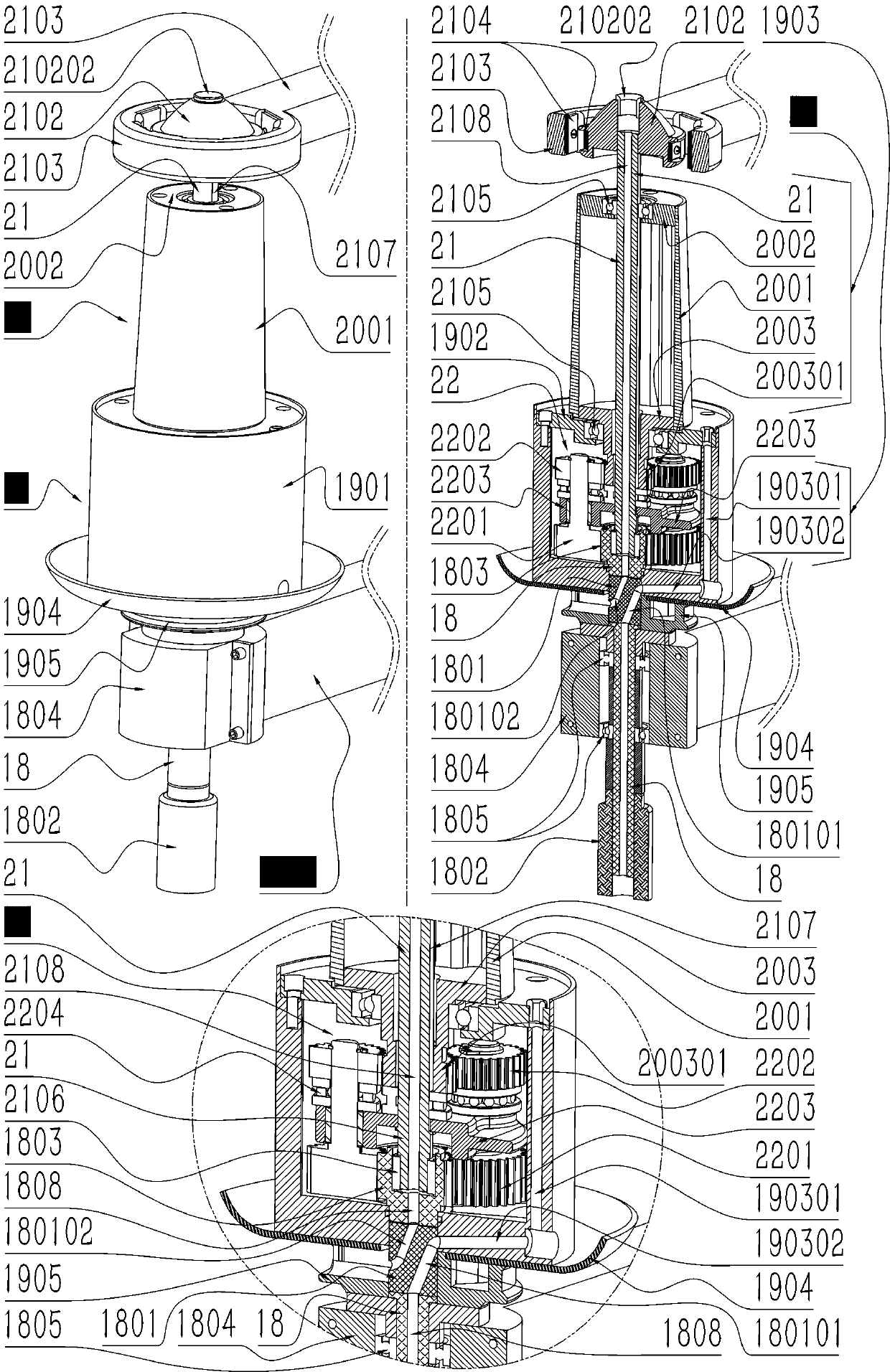

[0030] Specifically, a typical embodiment of a twisting device provided by the invention, such as Figure 4 shown and refer to figure 1 , like the traditional twisting device, it can also twist the multi-strand wire fed into it and then output it. like image 3 shown and refer to Figure 4 and Figure 5 The twisting device includes a twister for twisting the multi-strand wire and a support 1804 for installing the twister on the twister, image 3 In fact, only the twister and its support 1804 are displayed, Figure 5 What is shown is a step-by-step disassembly diagram of the twister and its support 1804 . Different from the traditional two-for-one twisting machine and the twisting device in the ring spinning frame, such as image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com