Prefabricated building cast-in-place pouring mold and pouring body and construction method thereof

A prefabricated and pouring mold technology, which is applied to the preparation of building components on site, construction, building construction, etc., can solve the problems of easy mold expansion and grout leakage, unqualified concrete quality, and difficult fixation, so as to reduce mold expansion and grout leakage, improve pouring quality, and easy fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

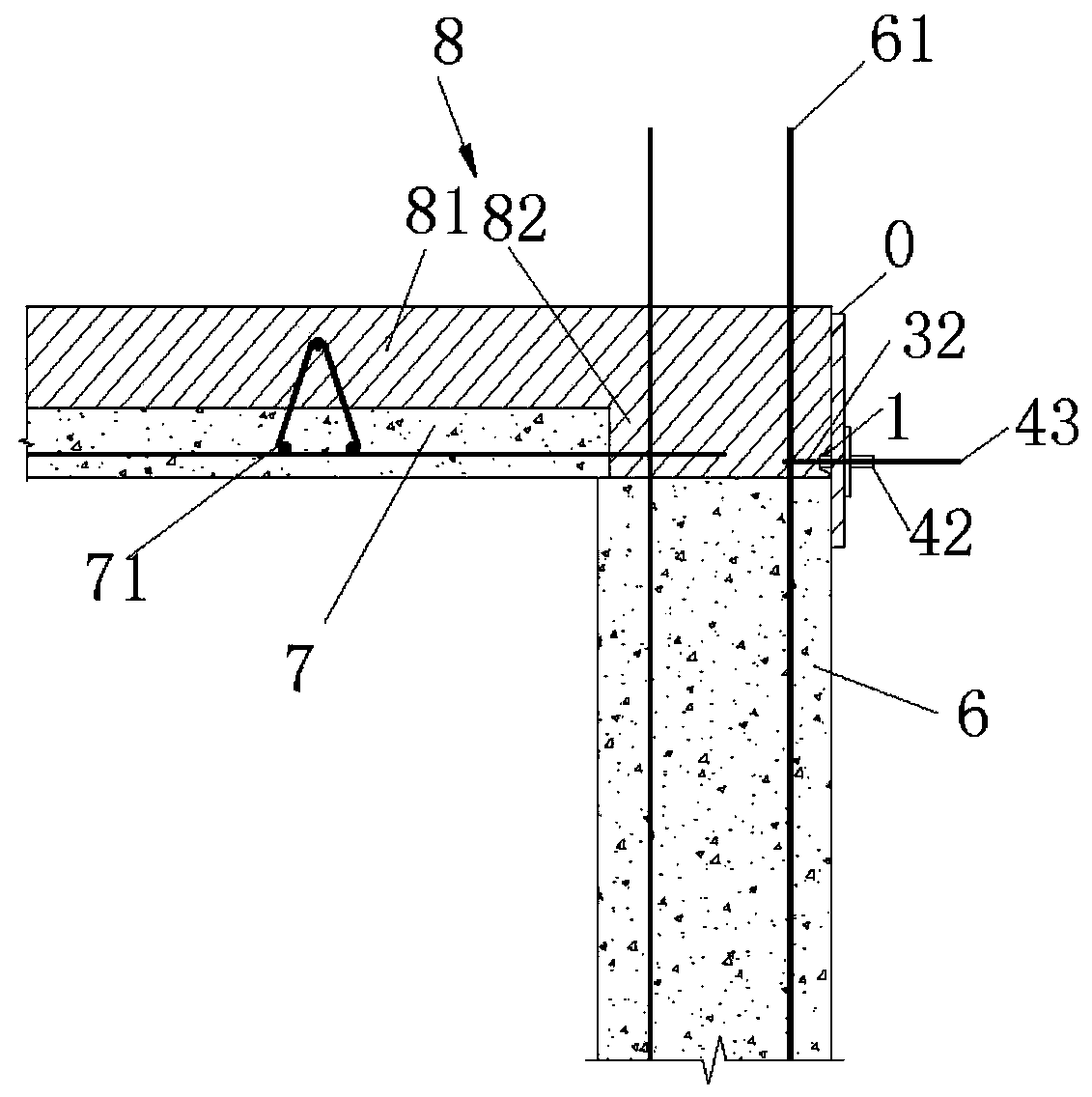

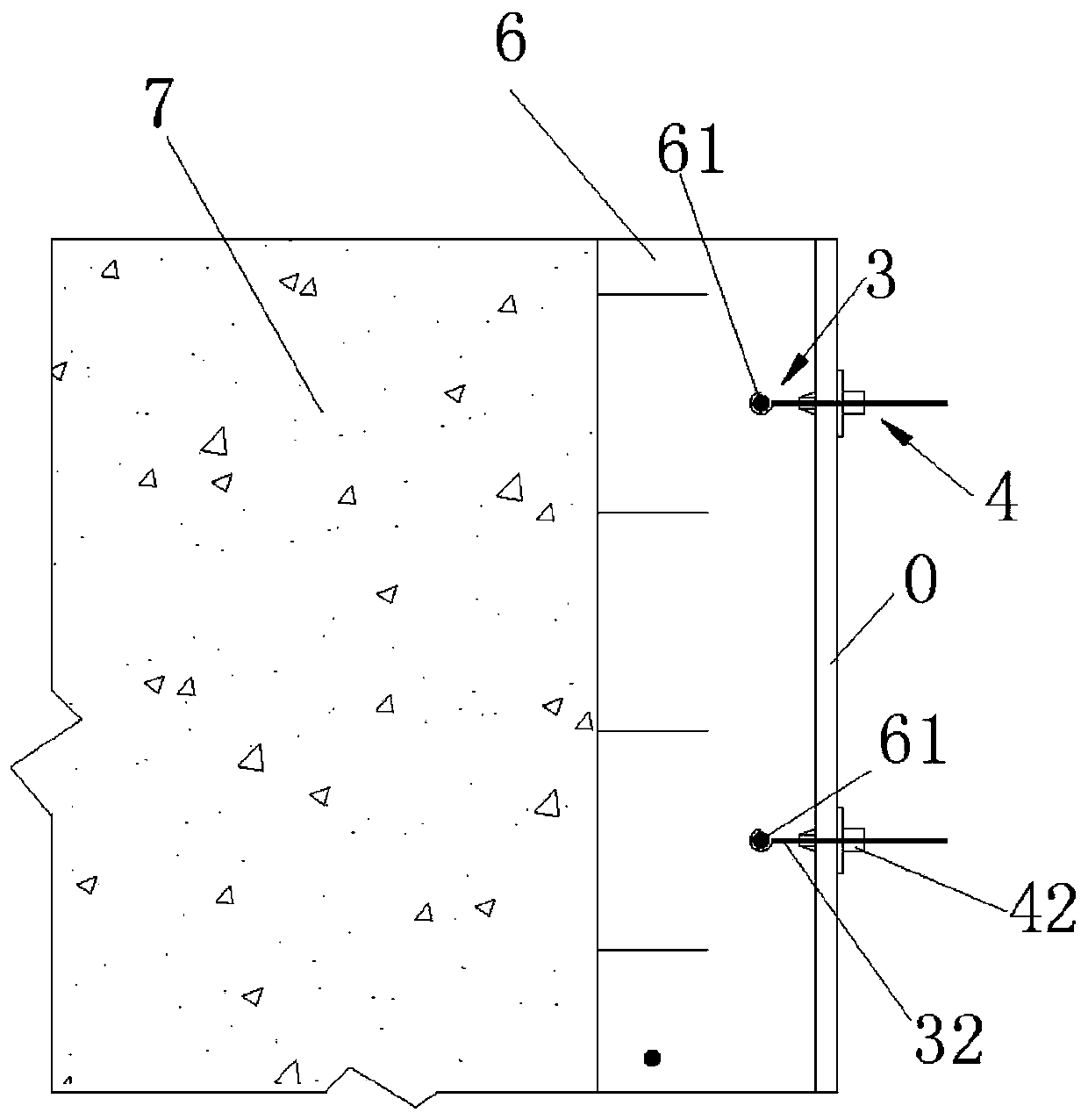

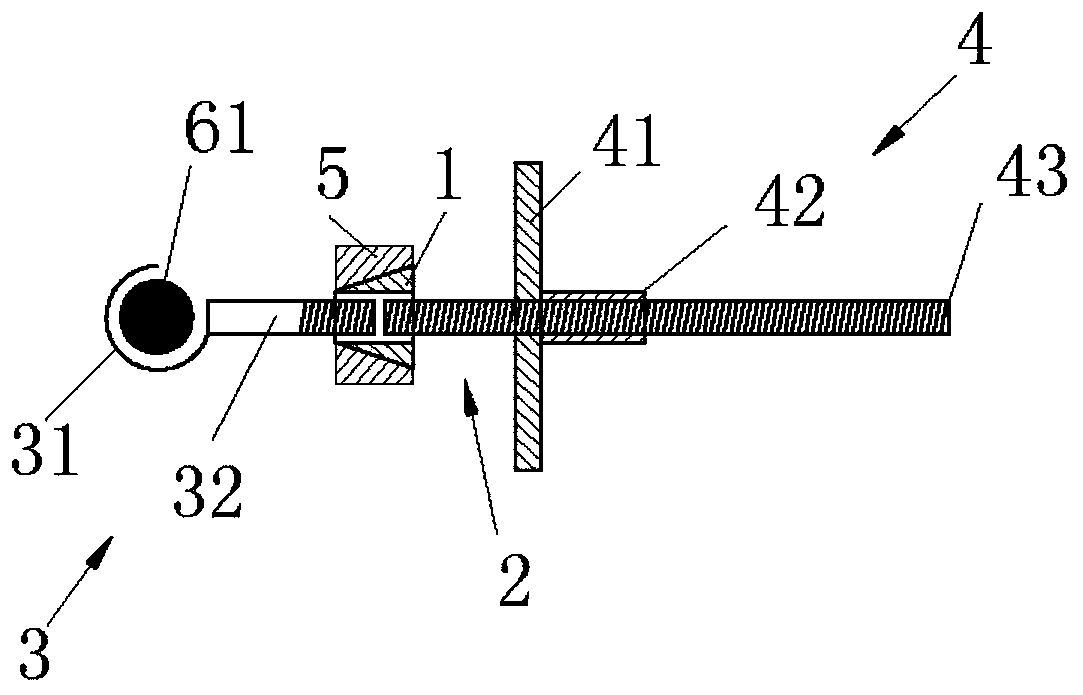

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] Such as Figure 1 to Figure 3 As shown, the prefabricated building cast-in-place casting mold of the present invention includes side mold 0 and side mold 0 reinforcing device, and the lower end of side mold 0 is used to be attached to the outer wall of the upper end of external wall PC member 6; The form 0 reinforcement device includes a detachable connector 1, a side form installation position 2, a hook assembly 3 for hooking the external external wall reinforcement 61 and a reinforcement assembly 4 for connecting the side form 0; the hook assembly 3 includes a hook 31 and the hook pull rod 32, the crotch 31 is welded on one end of the hook pull rod 32, the reinforcement assembly 4 includes a backing plate 41, a reinforcement nut 42 and an end screw 43, the reinforcement nut 42 is connected with the end screw 43, and the pad The plate 41 is sleeved on the en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap