control equipment for vehicles

A technology for controlling equipment and vehicles, applied in mechanical equipment, vehicle components, vehicle gearboxes, etc., can solve problems such as drivability degradation, and achieve the effects of simple transmission control, prevention of transmission stop, and reduction of torque transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

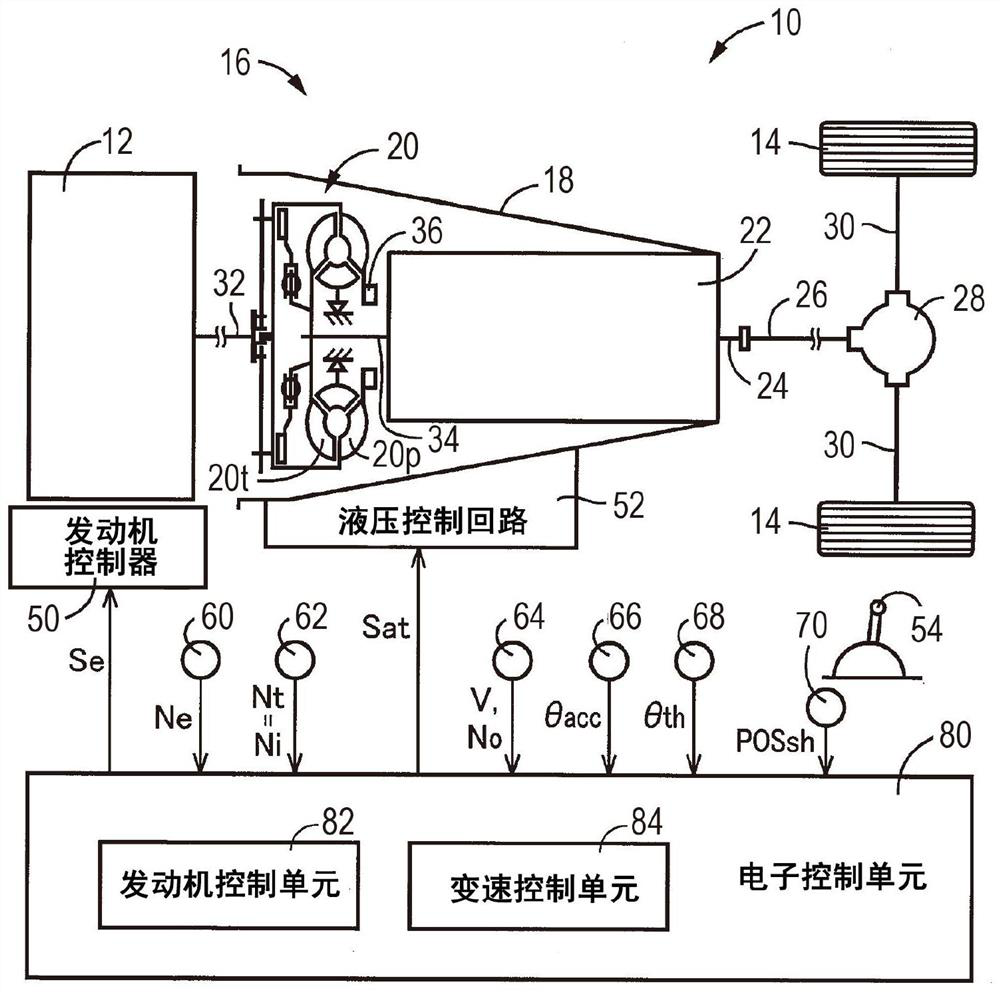

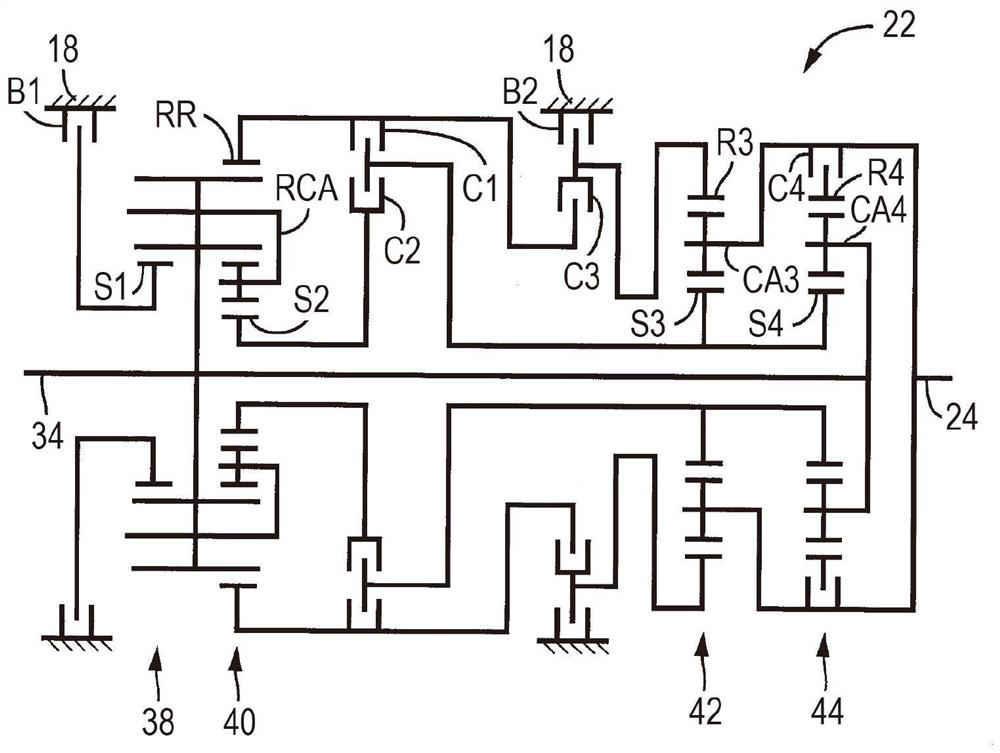

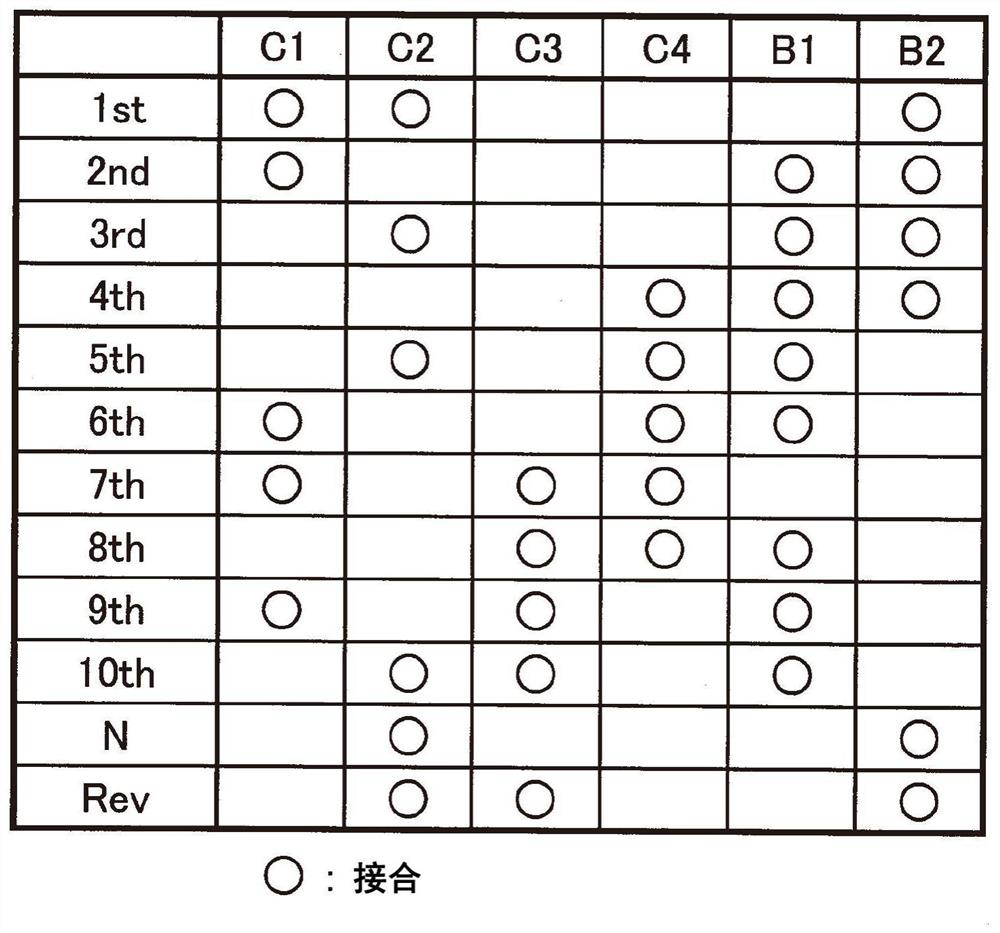

[0032] figure 1 is a diagram showing a schematic configuration of a vehicle 10 to which the present invention is applied, and is a diagram showing a main part of a control system for various controls in the vehicle 10 . Such as figure 1 As shown, the vehicle 10 includes an engine 12 as a power source, drive wheels 14 , and a power transmission device 16 provided in a power transmission path between the engine 12 and the drive wheels 14 . The power transmission device 16 includes a torque converter 20 and an automatic transmission 22 disposed inside a housing 18 that is a non-rotating component connected to the vehicle body. The power transmission device 16 includes a propeller shaft 26, a differential gear 28, a pair of drive shafts 30, and other parts. The prop shaft 26 is coupled to a transmission output shaft 24 which is the output rotating member of the automatic transmission 22 . A differential gear 28 is coupled to prop shaft 26 . A pair of drive shafts 30 are couple...

no. 2 example

[0076] In the first embodiment described above, in the shift control of the automatic transmission 22, the torque reduction control is executed. Torque reduction control may be performed only in shift control that may cause a large judder shock. In other words, the shift of the automatic transmission 22 that performs the torque reduction control is a predetermined shift that requires reducing the shock at the time of judder due to elimination of backlash in the automatic transmission 22 . For example, the predetermined shift is a shift control to change the automatic transmission 22 from the N position to the R position.

[0077] Figure 10 is a main part showing the control operation of the electronic control unit 80 (that is, in the shift control of the automatic transmission 22 for reducing the chattering while preventing the shift stop due to the delay of the engaging-side engaging device becoming engaged. The flow chart of the control operation of the impact). For exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com