Laser ultrasonic nondestructive detection system based on double-wave mixing

A laser ultrasonic and non-destructive testing technology, which is applied in the direction of measuring device, phase influence characteristic measurement, and material analysis through optical means, can solve the problem of small thermoelastic effect signal amplitude, etc., and achieve the goal of improving anti-interference ability and avoiding interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

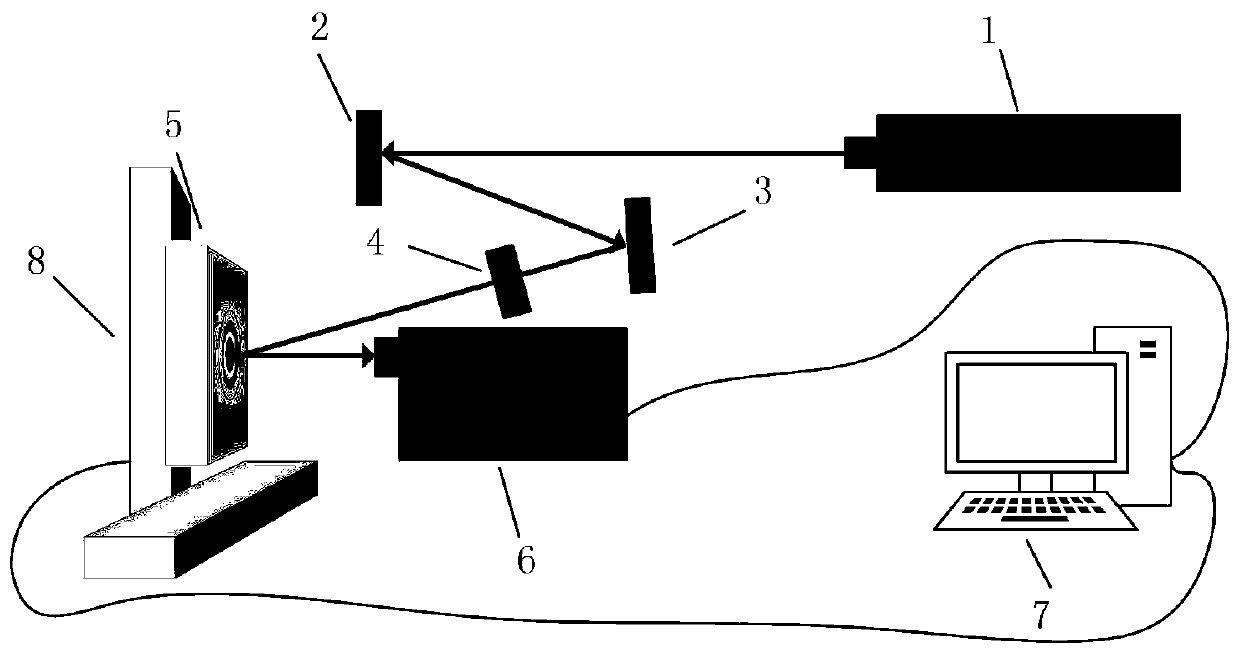

[0022] like figure 1 Shown is a schematic diagram of the system architecture. In this implementation example, the system includes a laser excitation module, a sample to be tested, a laser ultrasonic detection module, a host computer acquisition control module and a scanning mechanism;

[0023] The laser excitation module includes a pulsed laser 1 , a mirror 2 , a mirror 3 and a cylindrical mirror 4 . The pulsed laser 1 generates high-energy repetitive laser pulses and enters the cylindrical mirror 4 through the reflector 22 and the reflector 3, so that the point light source becomes a line light source and the intensity of the ultrasonic signal is increased.

[0024] The line light source is incident on the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com