Wire connection method for rotary electric machine, method for manufacturing rotary electric machine, wire connection structure for rotary electric machine, and rotary electric machine

A technology of rotating electrical machines and wiring methods, applied in the shape/style/structure of winding conductors, manufacturing motor generators, electromechanical devices, etc., can solve problems such as output reduction, reactive power loss, copper loss, etc., to suppress circulating current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0051] First, refer to Figure 1 to Figure 10 The first embodiment is described.

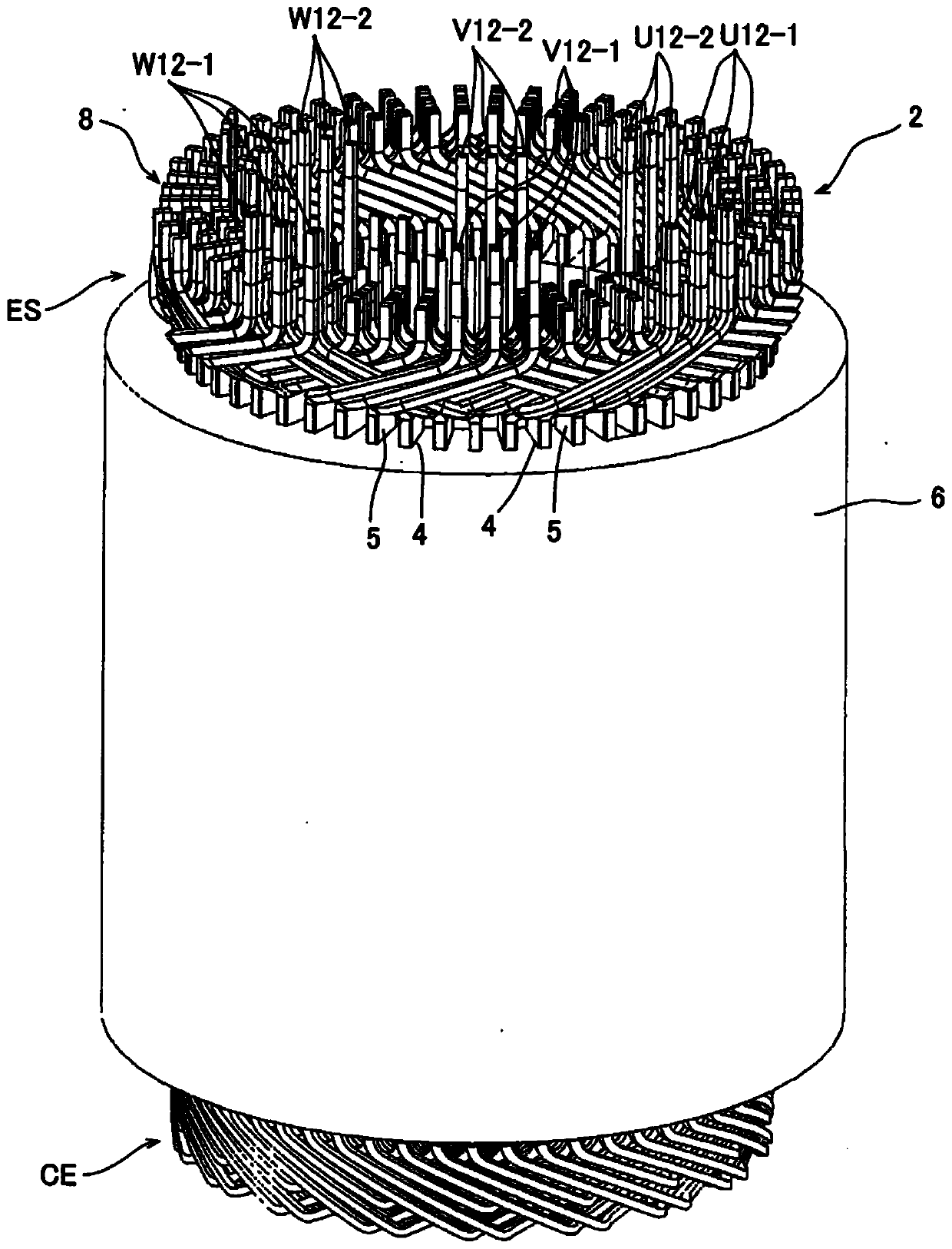

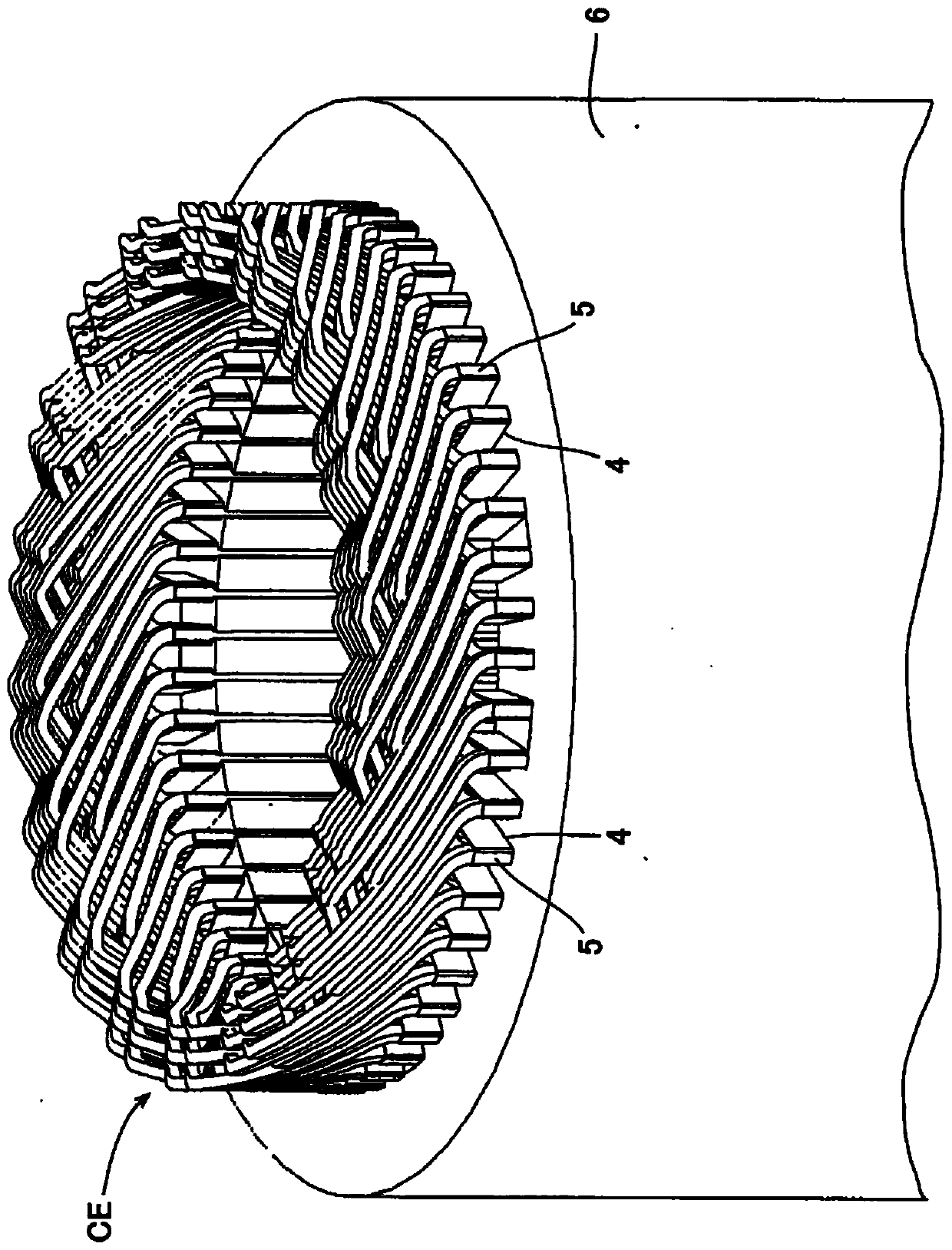

[0052] figure 1 and figure 2 The stator 2 having the wiring structure of the electric rotating machine according to the present embodiment is shown. figure 1 shows the entire stator 2, and figure 2 The coil end CE side of the stator 2 is shown.

[0053] The stator 2 includes a cylindrical core 6 having a plurality of circumferentially arranged slots 4 and coils 8 for three phases (U phase, V phase, W phase) by inserting U-shaped coil segments into the slots 4 and formed by connecting the ends of the coil segments in their insertion direction according to a predetermined pattern. The coil 8 has a six-layer structure.

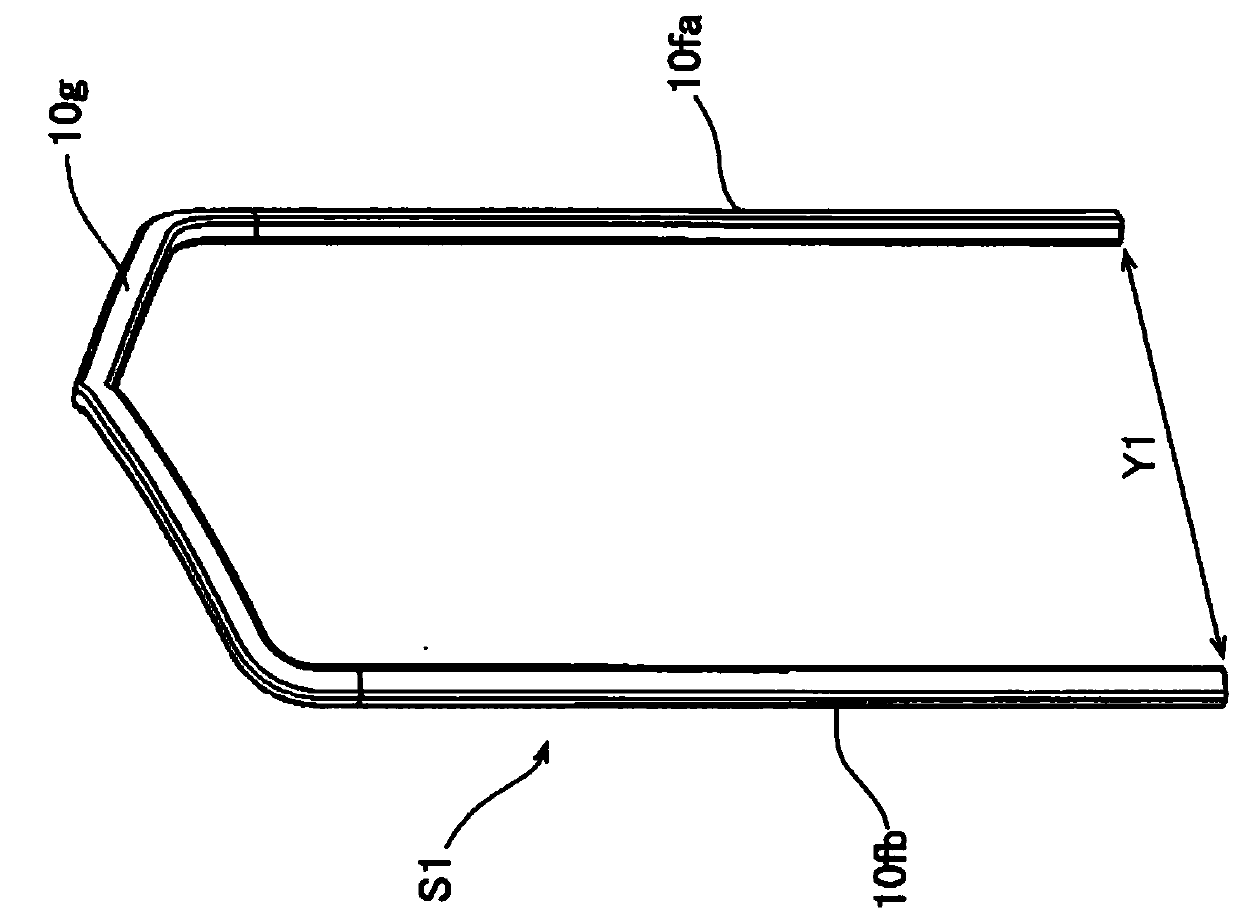

[0054] Each coil segment is inserted from the CE side of the coil end, and the end side of the insertion direction (i.e. figure 1 End portions of the illustrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com