Five-machine-head pure hydraulic hoop bending machine

A hoop bending machine and machine head technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of high failure rate, poor manual locking effect, complex structure, etc., to reduce the failure rate, and the drive system is simple and simple , Compact and concise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

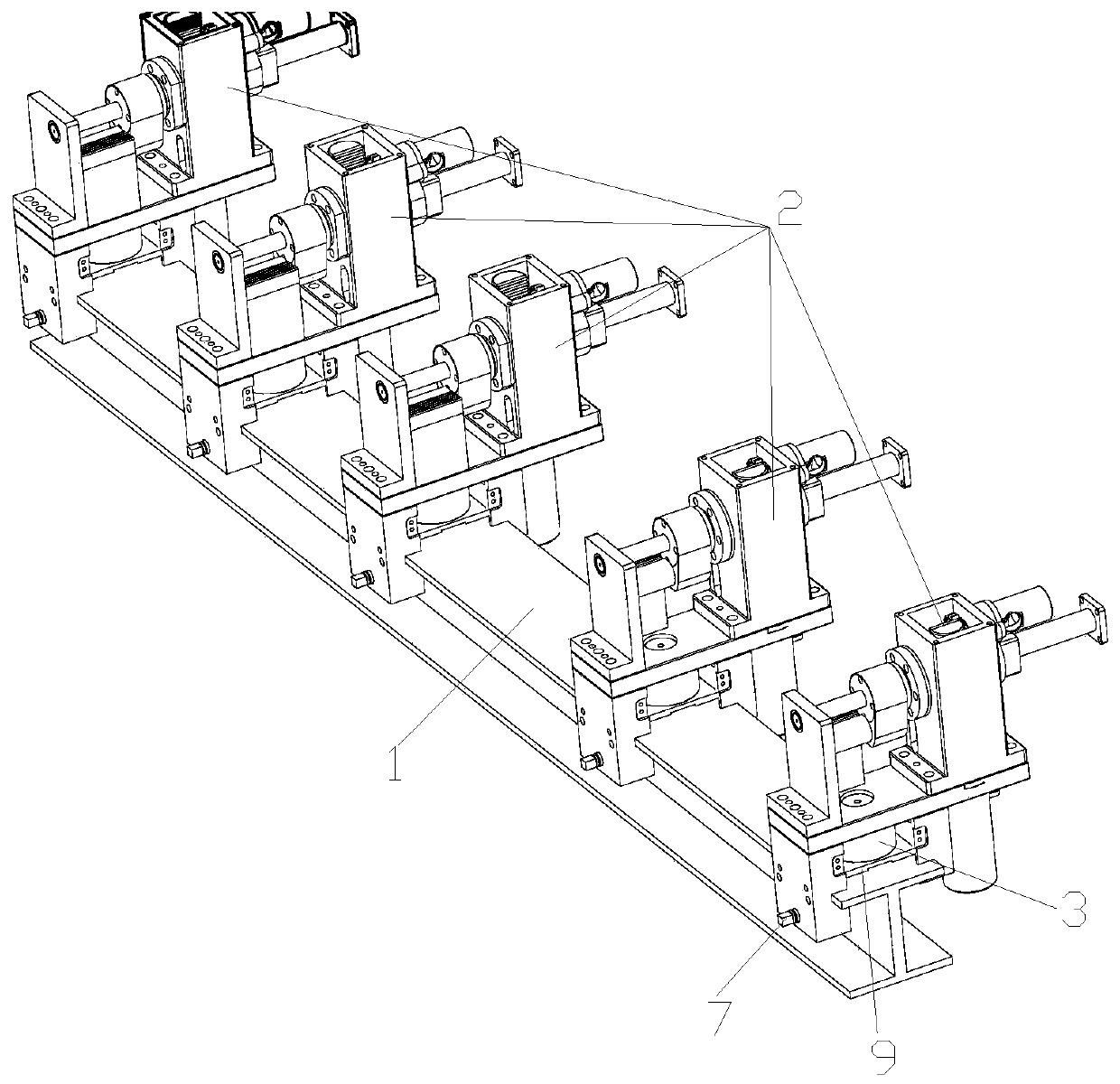

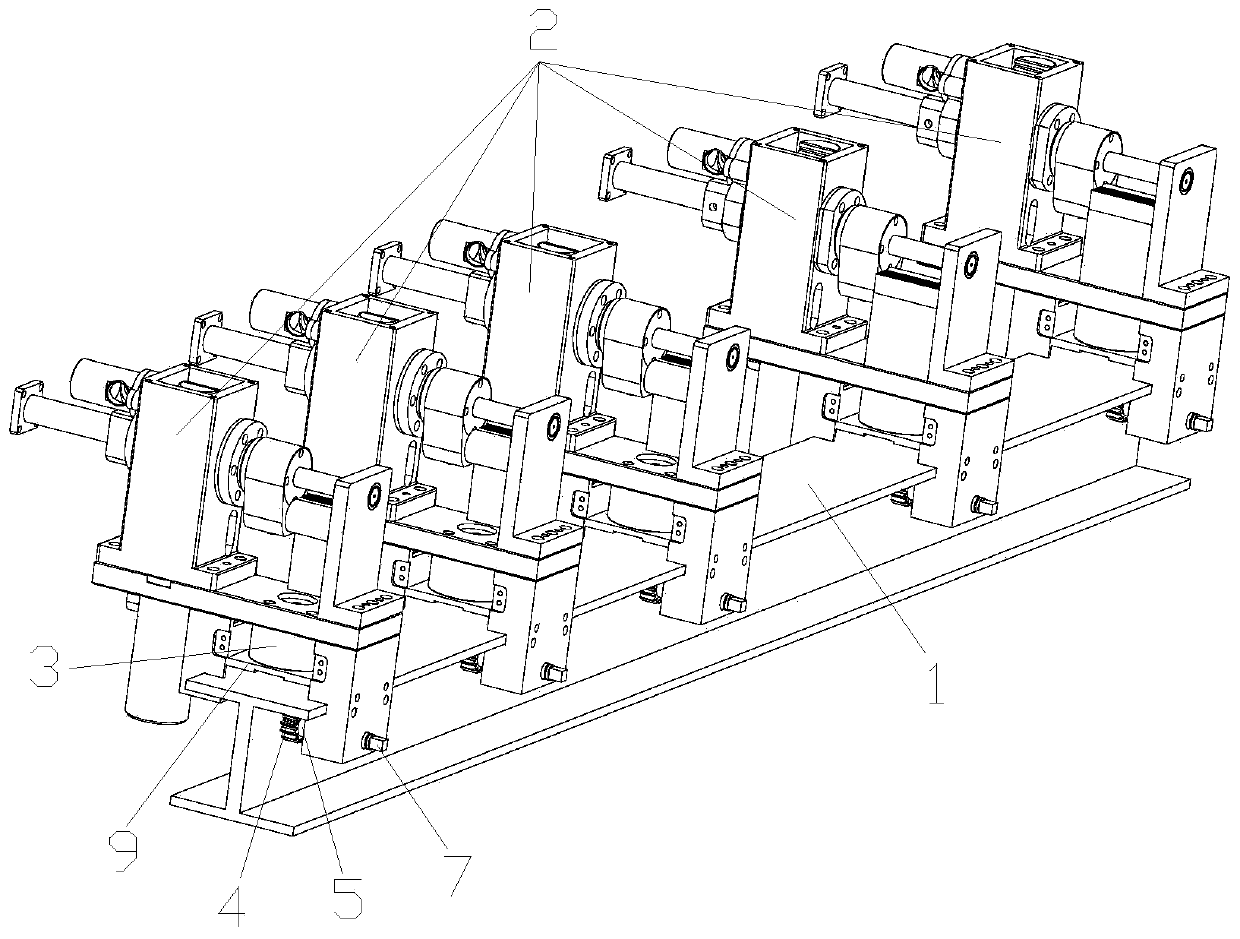

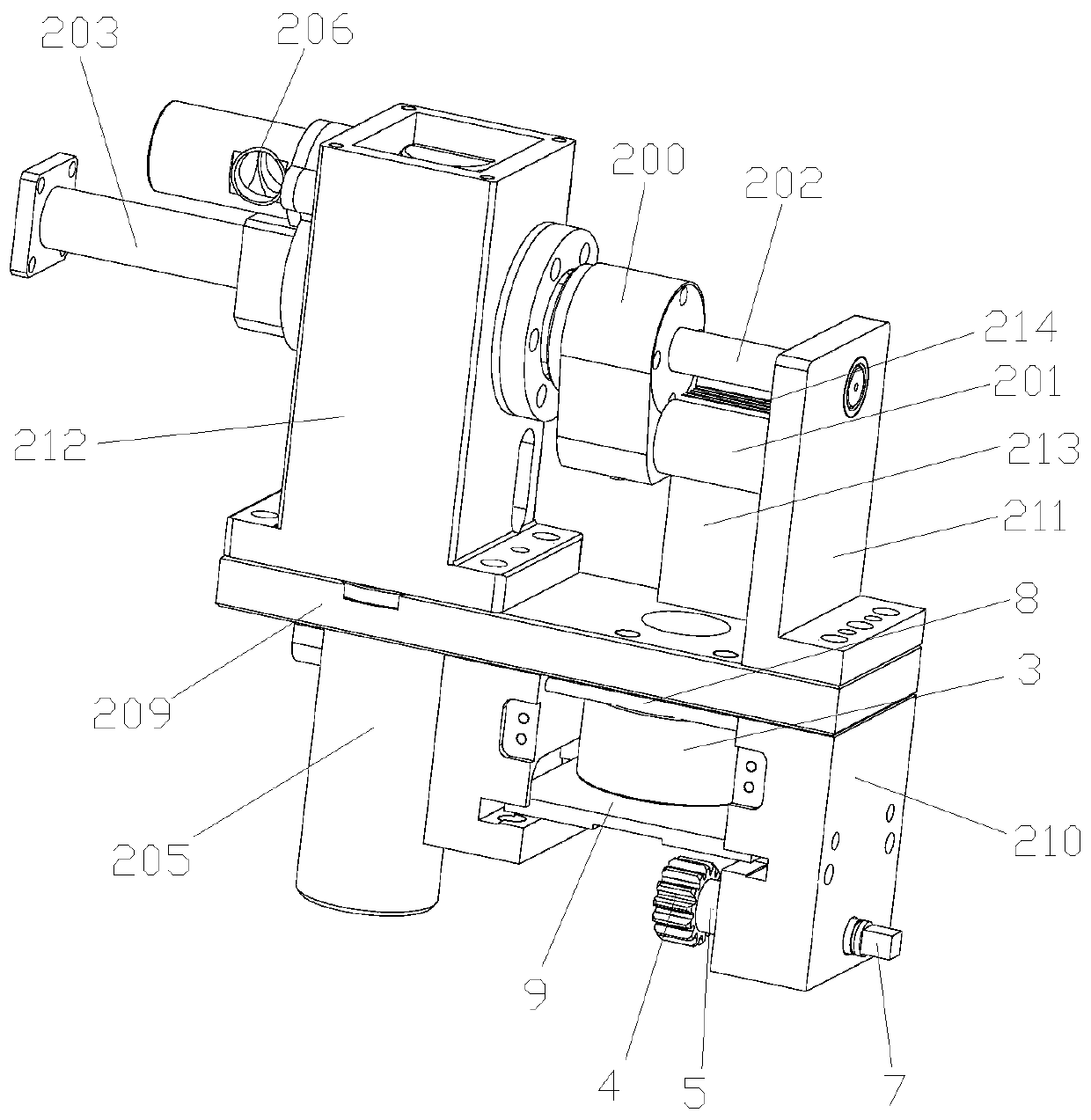

[0063] see figure 1 , figure 2 and image 3 , the present invention provides a five-head pure hydraulic hoop bending machine, which is used to bend steel bars into a bent state, especially realizes pure hydraulic drive, optimizes the design of the hydraulic station, makes the structure more compact and compact, and realizes hydraulic locking The machine head 2 makes the step of locking the machine head 2 more convenient and the locking effect is good.

[0064] In a specific embodiment, the five-head pure hydraulic hoop bending machine includes a machine base 1 and five machine heads 2, and the machine base 1 is the base of the five-head pure hydraulic hoop bending machine for placing the machine heads 2. The machine head 2 is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com