A concrete mixing device with up and down movement

A mixing device and concrete technology, which is applied in the direction of cement mixing device, clay preparation device, mixing operation control device, etc., can solve the problems of easy accumulation of dust, affecting the use and cleaning of transmission parts, and affecting the quality of concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with specific embodiments.

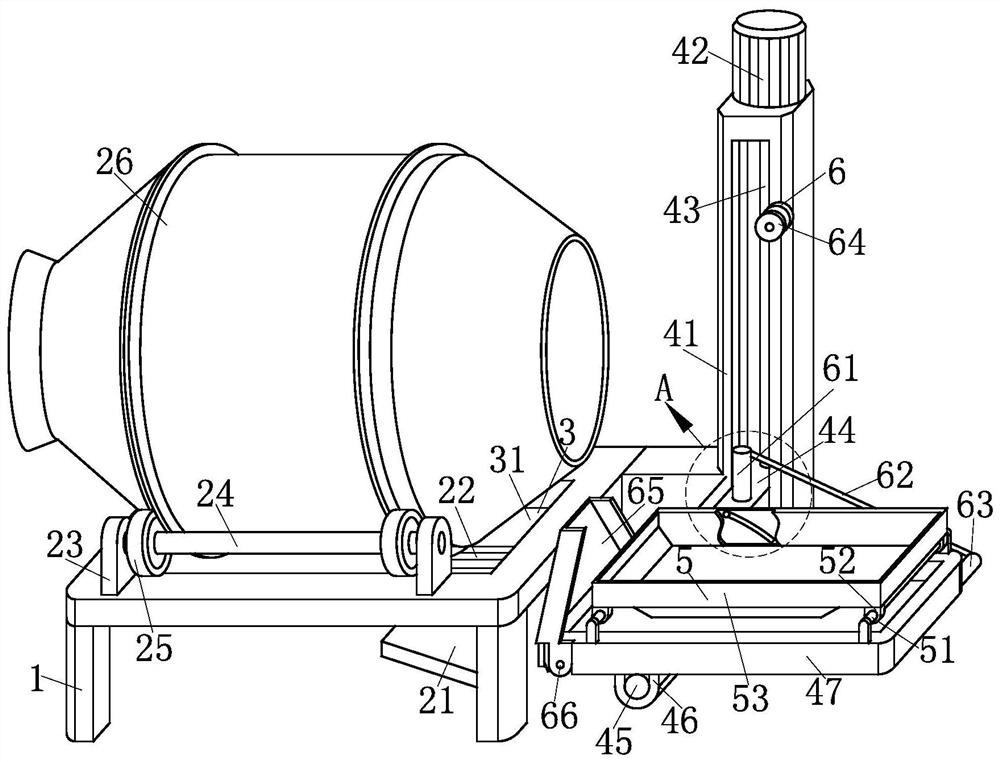

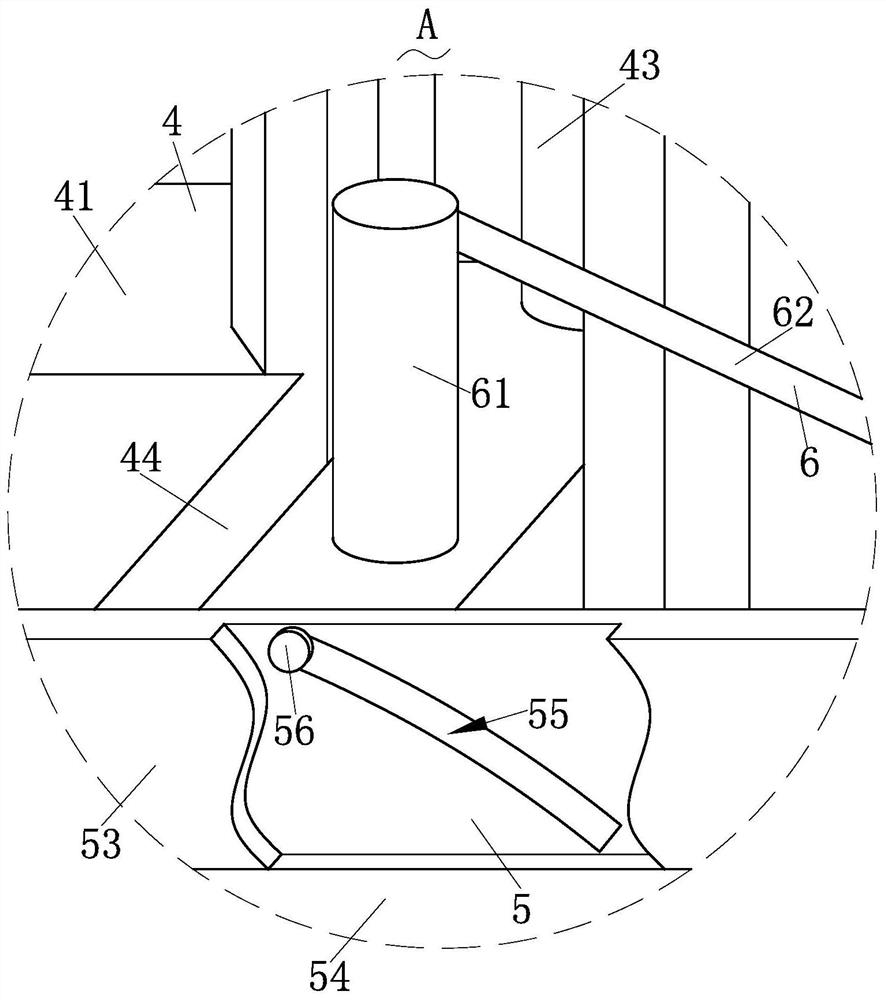

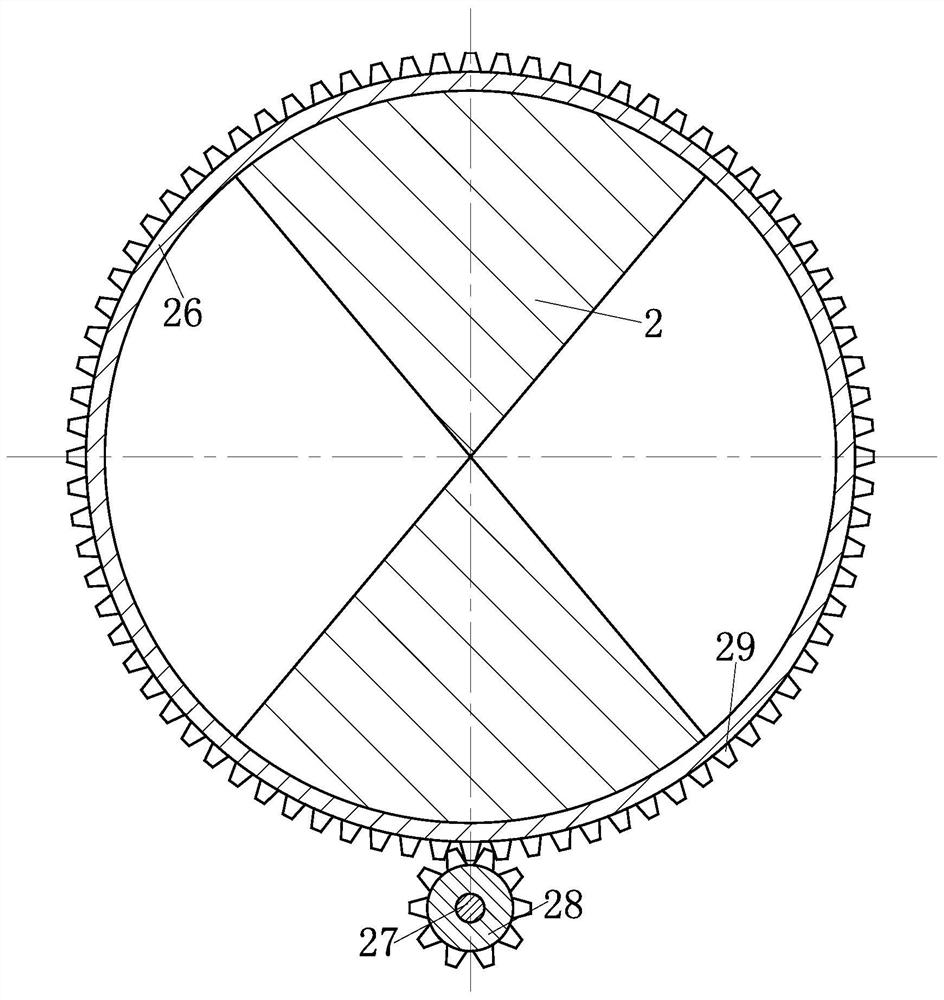

[0026] like Figure 1 - Figure 8 As shown in A of the present invention having a vertically moving concrete mixing apparatus includes a base 1, stirring structure 2, 3 cleaning structure, lifting structure 4, 5, and pouring structural screening structure 6, and support functions for the mounting base 1 to the top of other parts of the installation for the sand, water and cement the stirring was stirred structure 2; end of the structure 2 was stirred for mounting the stirring structure 2 in a cleaning the cleaning structure 3, one end of the mounting base 1 for sand and cement from the ground to lift the lifting structure of the stirred 4 structure 2; 4 at one end of the lifting of the structure for mounting the sand the heteroaryl sieved to the screening structure 5, one end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com