Automatic cycle loading and unloading type precision engraving machine and machining center

An automatic circulation and processing center technology, applied in metal processing, stone processing equipment, stone processing tools, etc., can solve the problems of high work intensity, low quality products, and high dependence on engineers and operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

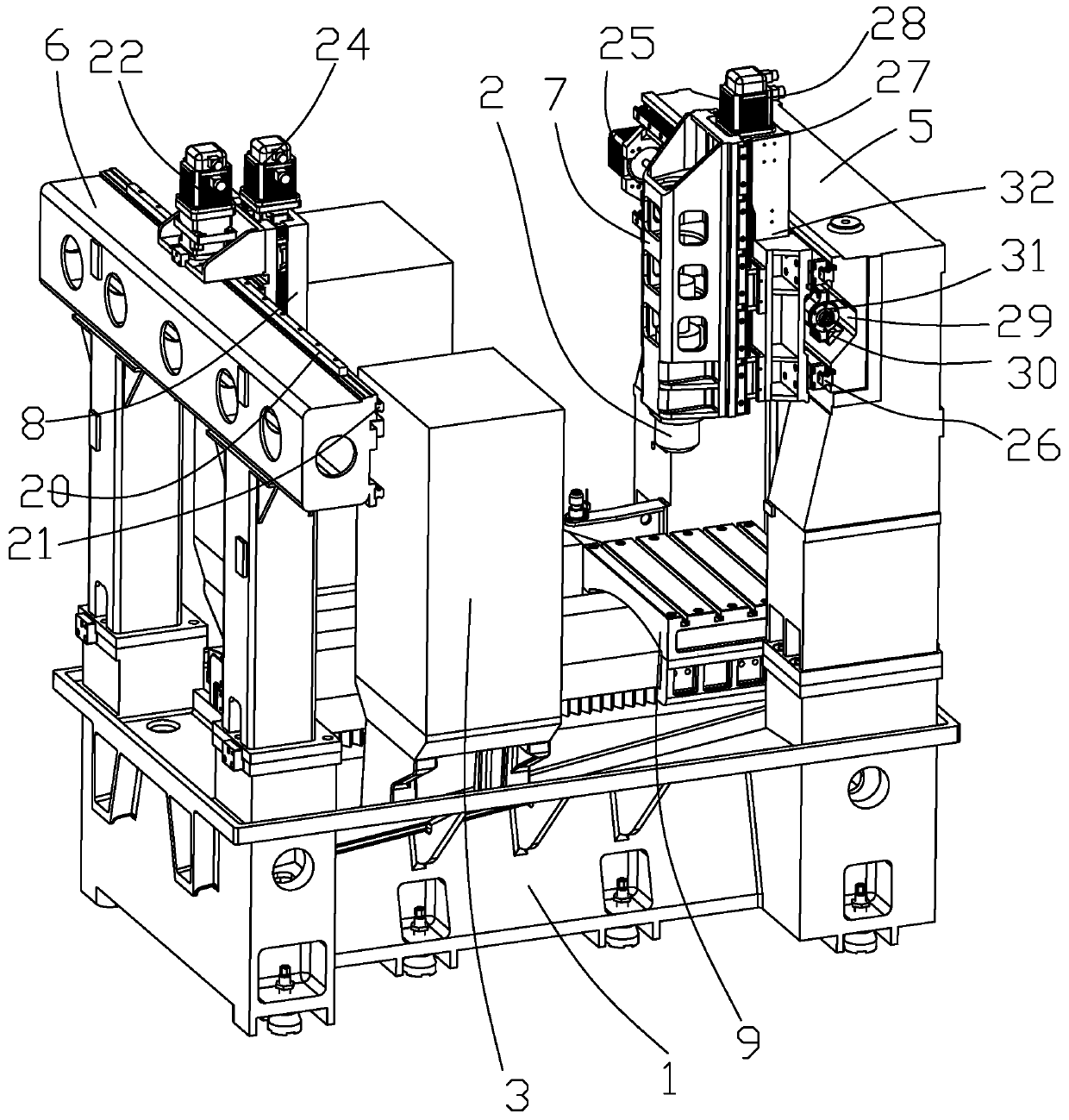

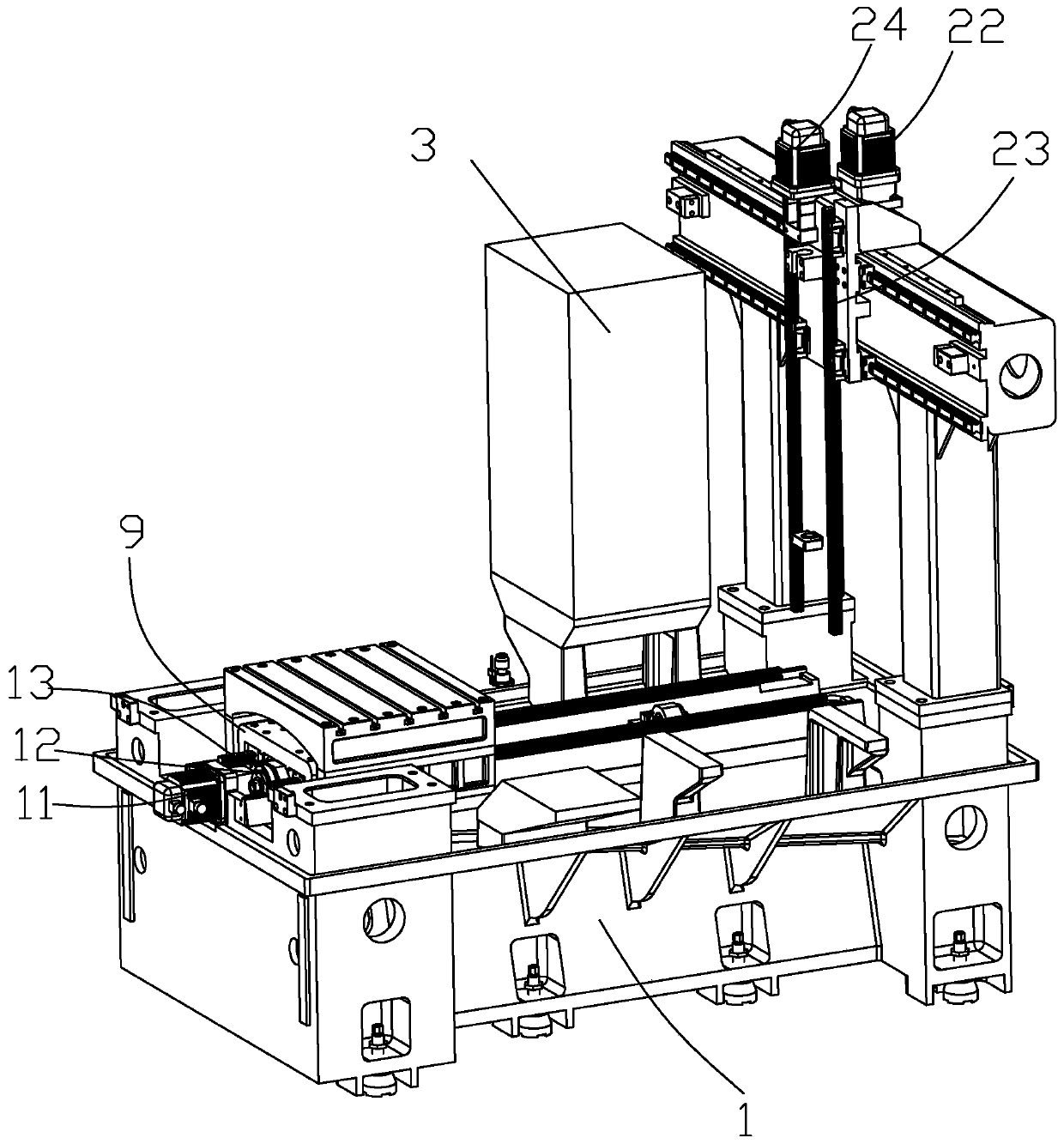

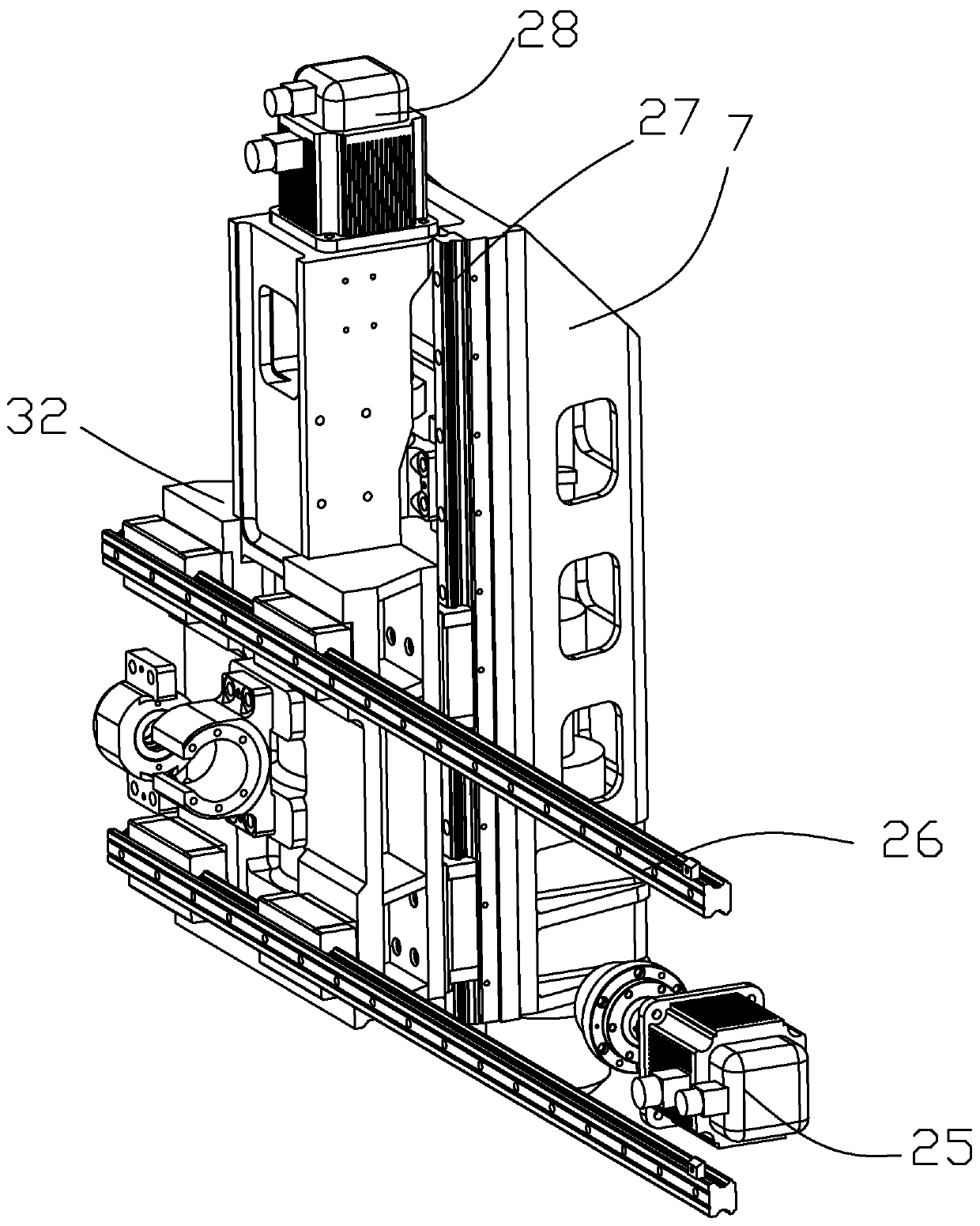

[0025] refer to Figure 1 to Figure 7 , the invention discloses an automatic circulation loading and unloading type engraving machine and a machining center, including a machine base 1, a knife magazine (not shown in the figure), a knife head 2 and a knife driving mechanism connected to the knife head 2, the knife magazine It is a disk-shaped chuck with a number of knives inserted thereon. The cutter head 2 and the tool magazine are of conventional structure, so the specific structure is not described in detail, including the transmission mechanism arranged on the machine base 1, a number of storage racks 3, a number of On the fixture plate 4 where the workpiece is placed, the gantry frame 1 5 arranged at one end of the machine base 1 and the gantry frame 2 6 arranged at the other end of the machine base 1, the gantry frame 1 5 is provided with a tool moving mechanism, and the cutter head 2 and the tool driving mechanism are installed on the tool frame 7, and the tool frame 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com