An integrated system for ink viscosity adjustment and ink filling control

A technology of ink viscosity and ink volume, which is applied in the field of the integrated system of ink viscosity allocation and ink supply control, can solve the problems of decreased printing quality and increased ink viscosity, and achieves the effect of balancing ink supply and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

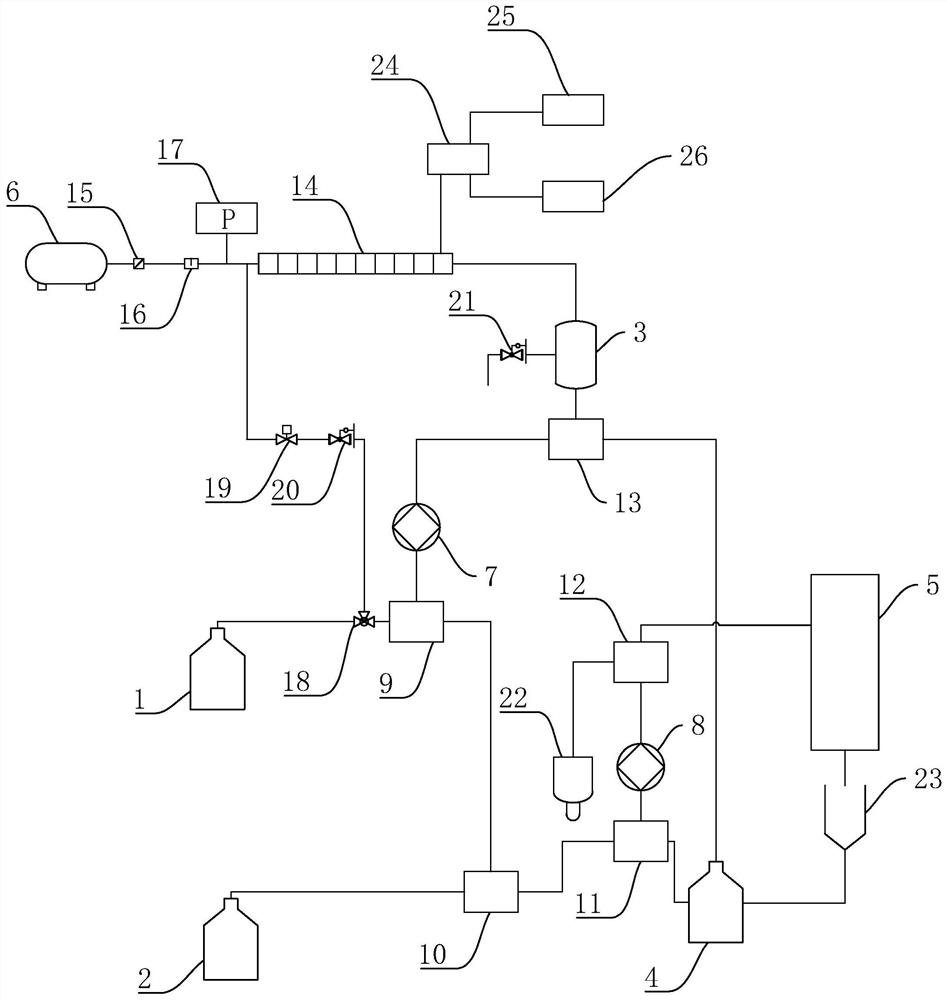

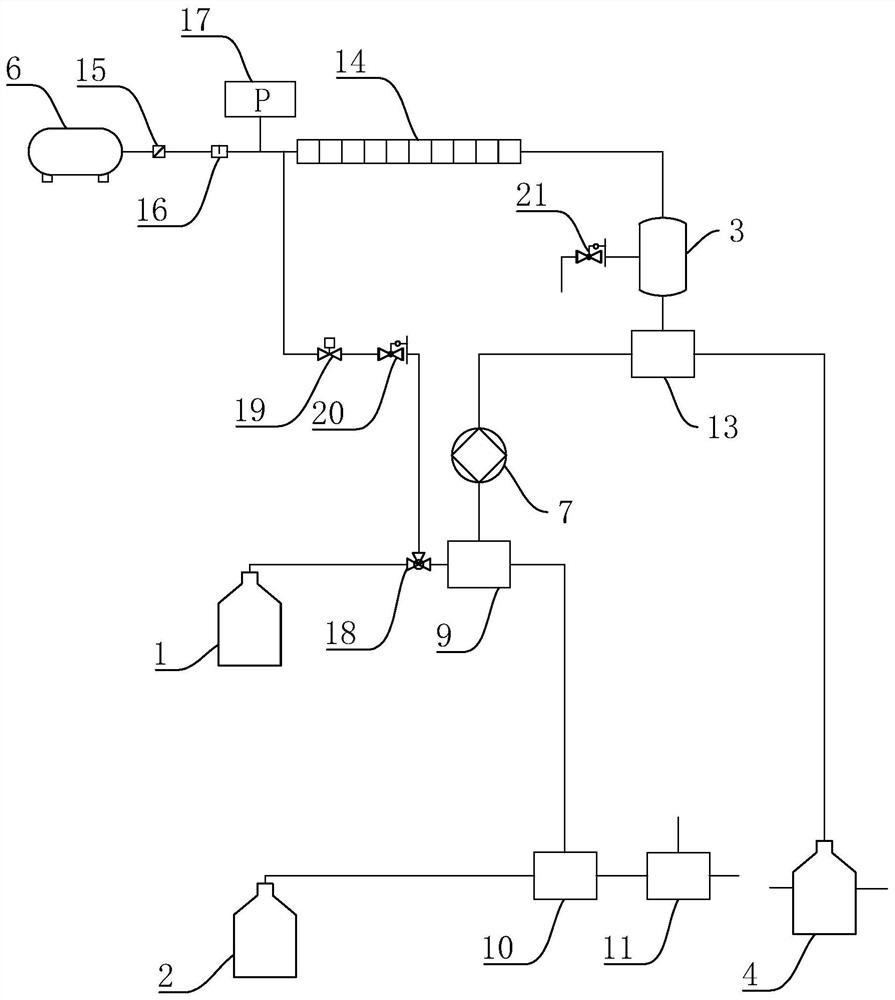

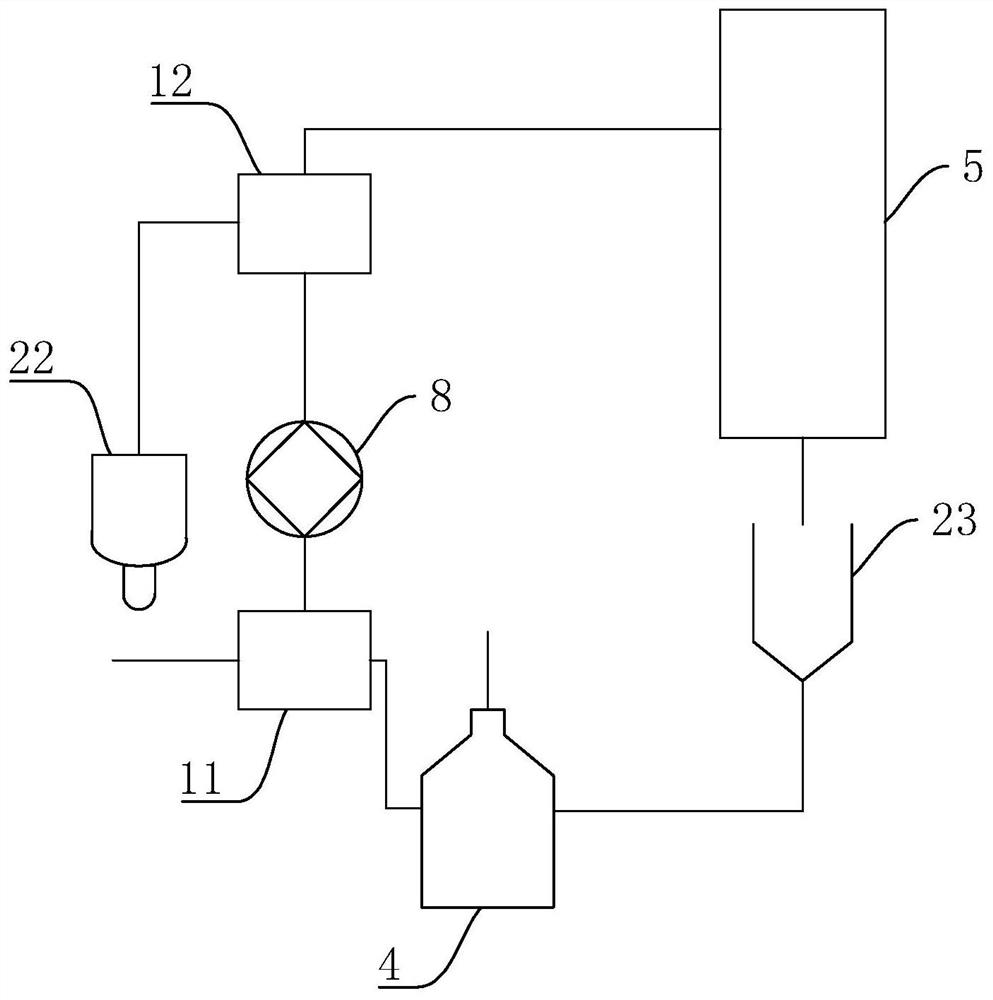

[0029] refer to figure 1 , is an integrated ink viscosity blending and ink filling control system disclosed in the present invention, including an original ink tank 1, a solvent tank 2, a mixing tank 3, a circulation tank 4, a pumping device and a viscosity measuring device 5. Among them, the pumping device includes compressed air power source 6, pneumatic valve group 14, controller 24, signal input terminal 25, diaphragm pump one 7, diaphragm pump two 8, pneumatic three-way valve one 9, pneumatic three-way valve two 10, Pneumatic three-way valve three 11, pneumatic three-way valve four 12 and pneumatic three-way valve five 13.

[0030] refer to figure 1 , the compressed air power source 6 adopts an air compressor, which not only provides power for the diaphragm pump 1 7 and the diaphragm pump 2 8, but also supplies air for the pneumatic valve group 14 to control the pneumatic three-way valve one 9, the pneumatic three-way valve two 10, and the pneumatic three-way valve group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com