Liquid outlet device used for frosting processing

A liquid storage and moving cavity technology, applied in the field of frosting processing, can solve the problems of low configuration ratio, the medicine box does not have the stirring function, and the effect of frosting is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

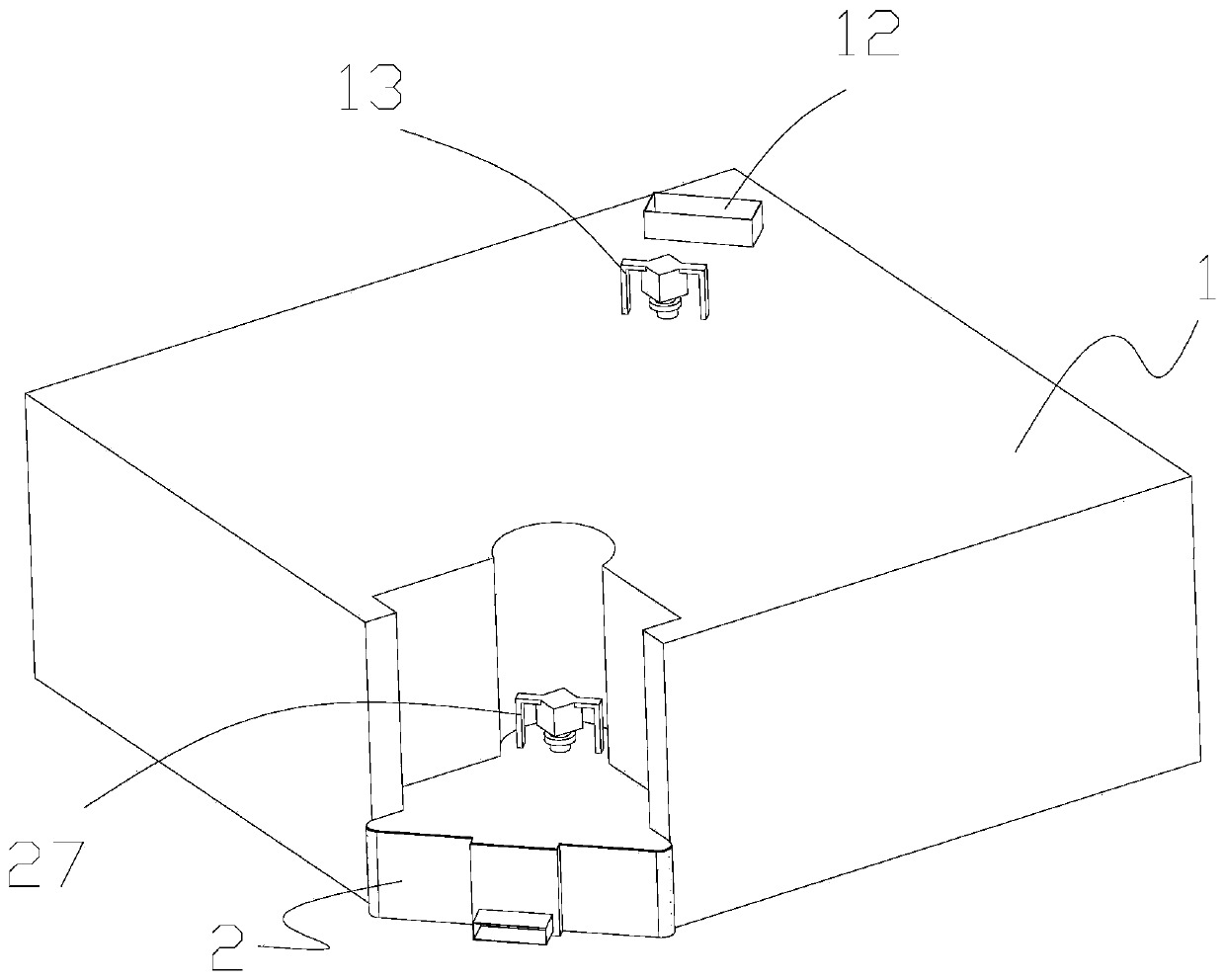

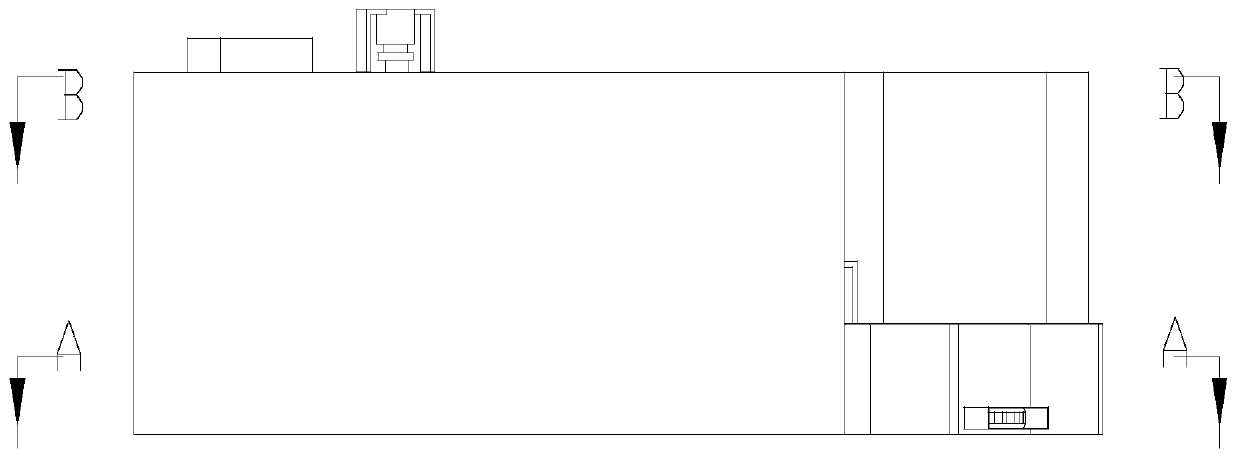

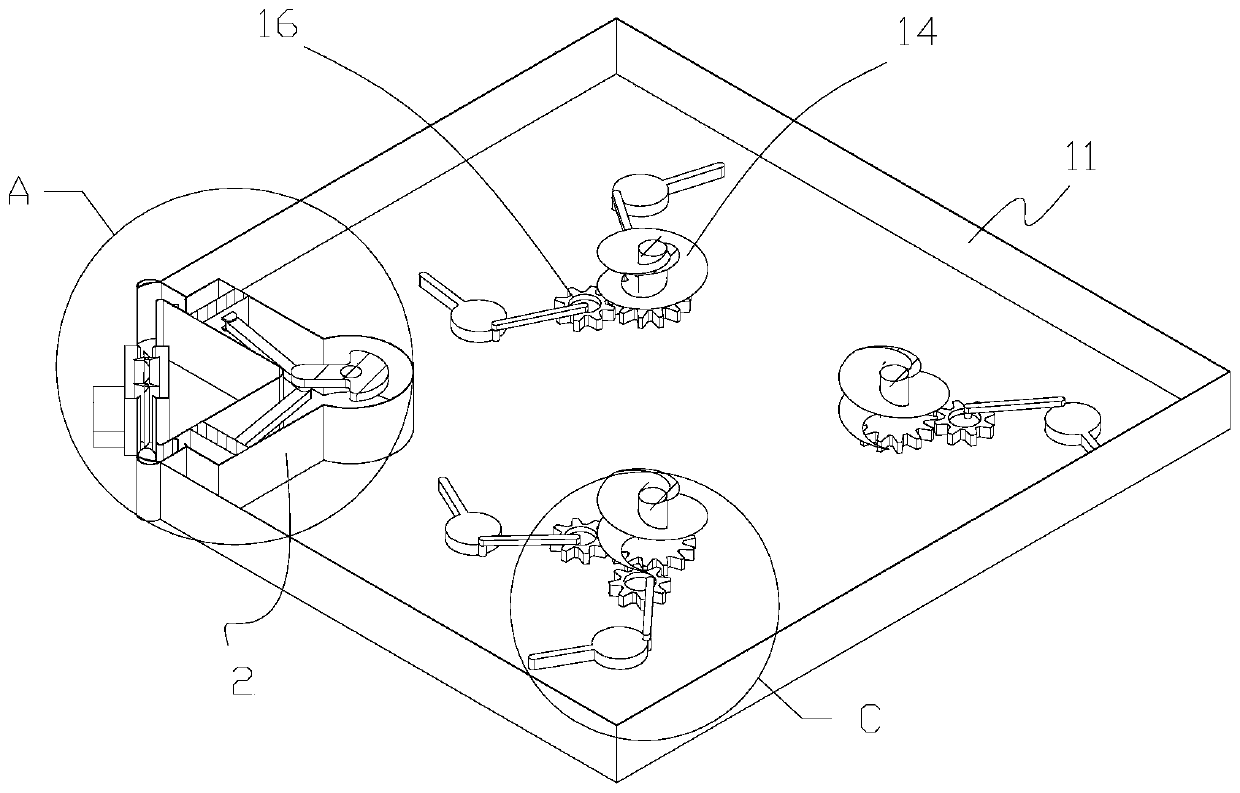

[0029] like Figure 1-10 As shown, a liquid outlet device for frosting processing includes a liquid storage mechanism 1 and a liquid outlet mechanism 2; the liquid outlet mechanism 2 includes a first box body 21, a rotating chamber 22, a mixing chamber 23, a first moving Chamber 24, second moving chamber 25, rotating block 26, first motor assembly 27, first piston 28, second piston 29, first connecting rod 30, second connecting rod 31, first slot 32, first single One-way valve 33, second slot 34, second one-way valve 35, liquid outlet 36, third one-way valve 37 and mixing part 38; the rotating chamber 22, mixing chamber 23, first moving chamber 24, second Two moving cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com