Antibacterial PP melt-blown material, melt-blown filter element and preparation method of melt-blown filter element

A melt-blown filter element and melt-blown technology, which are applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of low sterilization efficiency and poor filter stability, so as to improve water purification effect and antibacterial performance. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

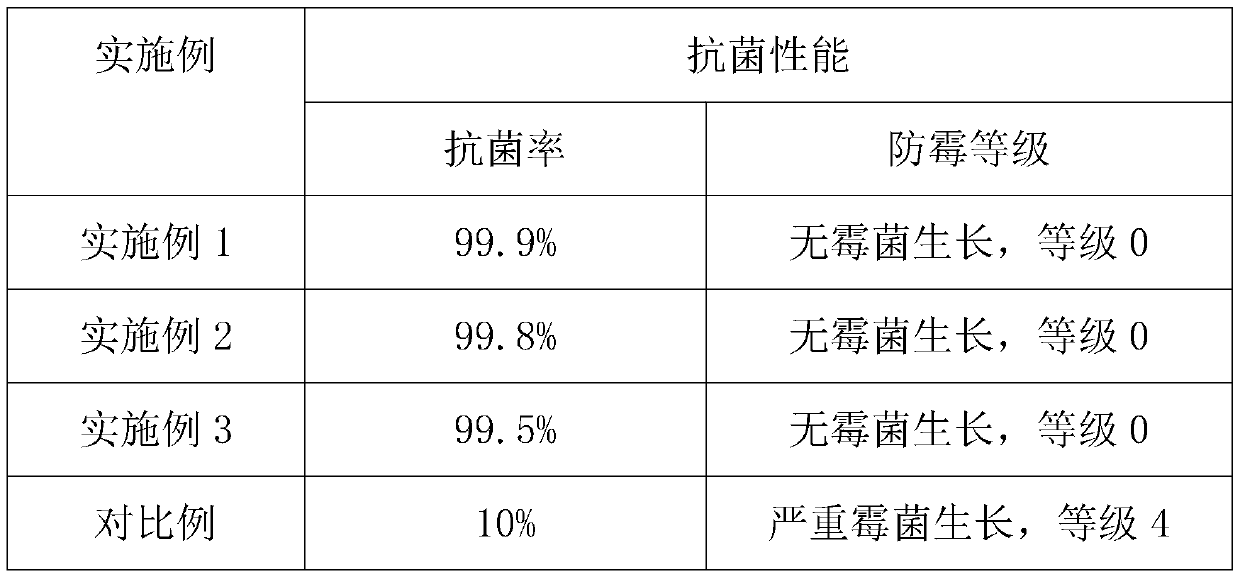

Embodiment 1

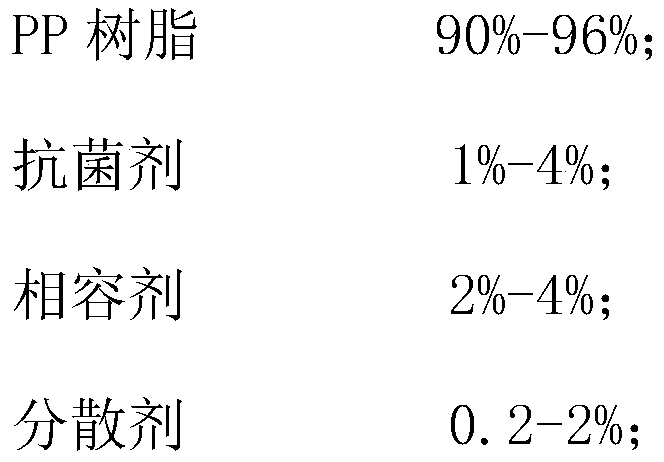

[0027] An antibacterial PP melt-blown material, comprising: 90g of PP resin (such as Shandong Dawn shares Z-1200), 4g of polyhexamethylene guanidine antibacterial agent, 4g of compatibilizer polypropylene grafted maleic anhydride, 2g Dispersant polyethylene wax.

[0028] An antibacterial PP melt-blown filter element is prepared from the above-mentioned antibacterial PP melt-blown material, and the preparation method includes the following steps:

[0029] Step 1: Prepare the auxiliary agent mixture; add the antibacterial agent, compatibilizer and dispersant in the formulated amount into the mixer, mix and stir evenly, and obtain the auxiliary agent mixture.

[0030] Step 2: Prepare the antibacterial PP melt-blown powder mixture; put the PP resin of the formula into the mixer, stir for 1-5 minutes, such as 2 minutes, then add the additive mixture into the PP resin, and stir for 5-20 minutes Minutes, such as 10 minutes, to obtain the antibacterial PP melt-blown powder mixture. ...

Embodiment 2

[0036] An antibacterial PP meltblown material, comprising: 95g of PP resin, 4g of polyhexamethylene guanidine antibacterial agent, 3.9g of compatibilizer polypropylene grafted maleic anhydride, 2.1g of dispersant polyethylene wax.

[0037] An antibacterial PP melt-blown filter element is prepared from the above-mentioned antibacterial PP melt-blown material, and the preparation method is the same as in Example 1.

Embodiment 3

[0039] An antibacterial PP meltblown material, comprising: 98g of PP resin, 3g of polyhexamethylene guanidine antibacterial agent, 3g of compatibilizer polypropylene grafted maleic anhydride, 2g of dispersant polyethylene wax.

[0040] An antibacterial PP melt-blown filter element is prepared from the above-mentioned antibacterial PP melt-blown material, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com