A surface treatment device for the internal thread of a building reinforcement sleeve

A surface treatment device, a technology for building steel bars, applied in the direction of metal material coating process, etc., can solve the problems of unreusable steel sleeves, inconvenient separation of steel bars, damage to internal threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

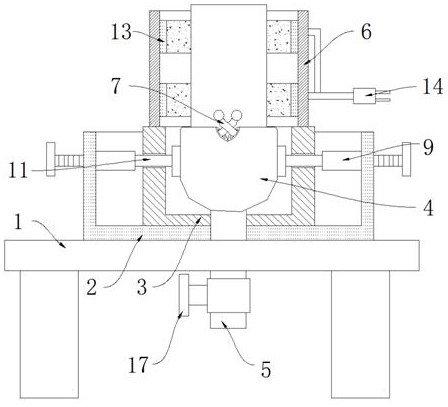

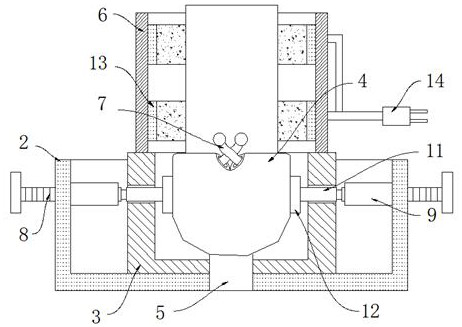

[0023] refer to Figure 1-3 , a surface treatment device for the inner thread of a building reinforcement sleeve, comprising a base 1, an outer container 2 is fixedly connected to the upper surface of the base 1, an inner container 3 is fixedly connected to the inside of the outer container 2, and both the outer container 2 and the inner container 3 are Cylindrical upper opening structure, and the centers of the two coincide.

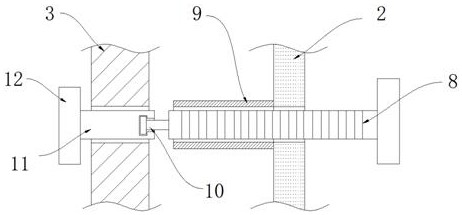

[0024] The outer surface of the base outer container 2 is threadedly connected with multiple clamping mechanisms extending to the inner container 3. The multiple clamping mechanisms are located at one end of the inner container 3 and are fixedly connected with a soft bucket 4. The lower surface of the soft bucket 4 is fixedly connected with The drain pipe 5 communicating with the inside, the upper end of the inner container 3 is fixedly connected with a cylindrical cover pipe 6, the material of the soft bucket 4 is high temperature resistant rubber, and...

Embodiment 2

[0028] refer to Figure 4 , and the difference from Embodiment 1 is that a bottom plate 15 is fixedly connected between the supporting legs of the base 1, and a horizontal electric heating furnace 16 is fixedly connected on the upper surface of the bottom plate 15, and the upper surface of the horizontal electric heating furnace 16 is connected with the drain pipe 5 Opening and closing valve 17 is arranged on the surface of discharge pipe 5, and a liquid intake port is provided on the upper surface of horizontal electric heating furnace 16. The sealing cover 18, the left side of the horizontal electric heating furnace 16 is provided with a blowdown pipe 19, the surface of the blowdown pipe 19 is provided with a control valve 20, the horizontal electric heating furnace 16 is a resistance furnace, and the surface is provided with a temperature indicator.

[0029] When using the surface treatment device for the internal thread of the construction steel bar sleeve proposed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com