Shield tunneling machine cutterhead structure with telescopic geological drills

A technology of geological drilling and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems of high cost and complicated process, and achieve the effects of reducing wear rate, protecting tools and improving the efficiency of shield tunneling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the purpose, technical solution and technical effect of the present invention, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments. At the same time, it is stated that the embodiments described below are only used to explain the present invention, and are not intended to limit the present invention.

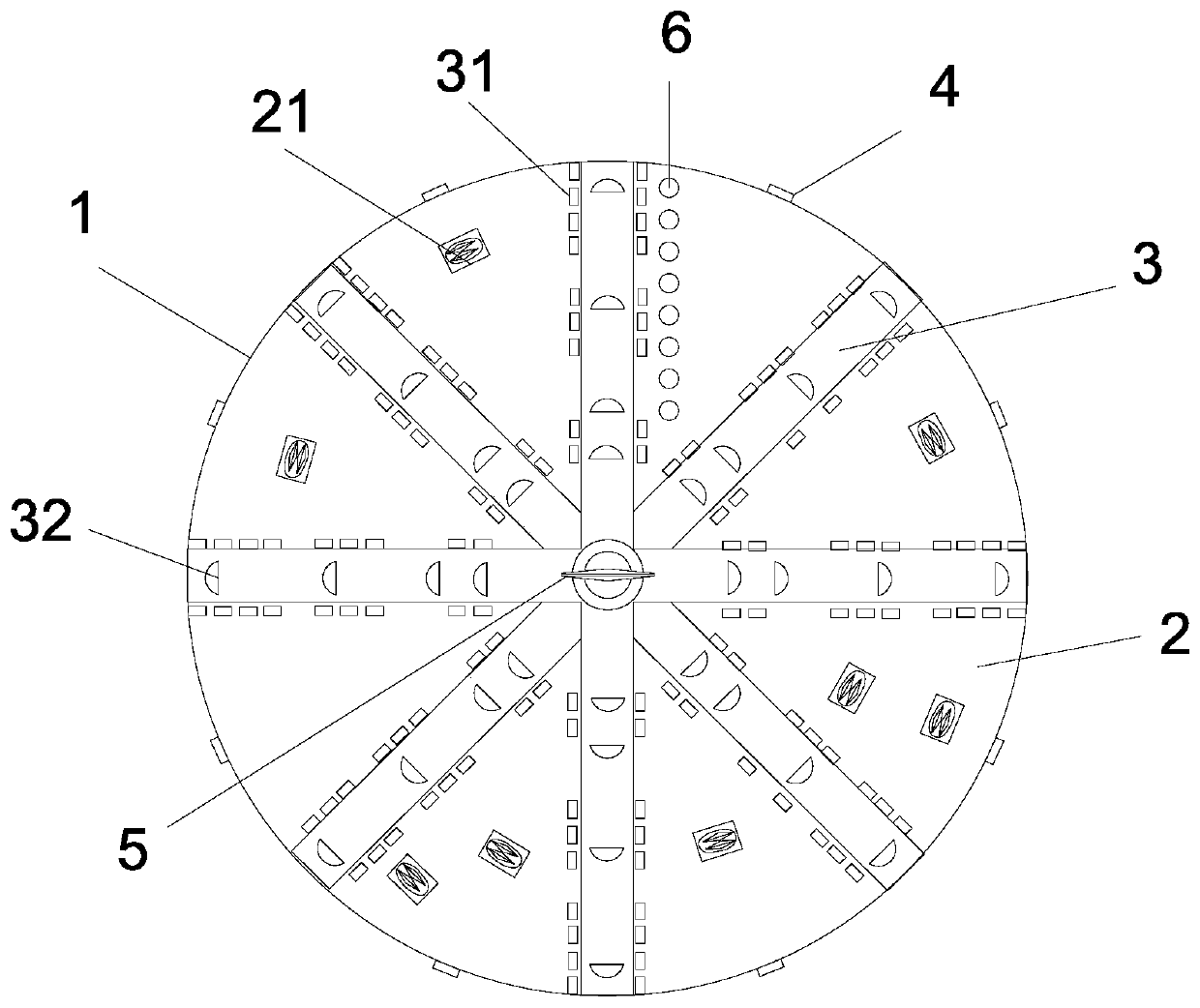

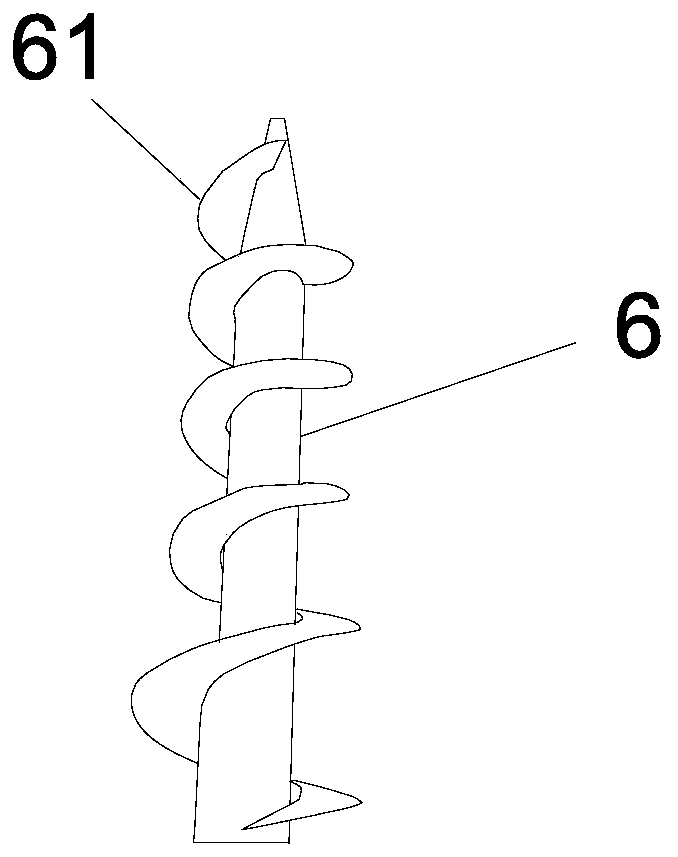

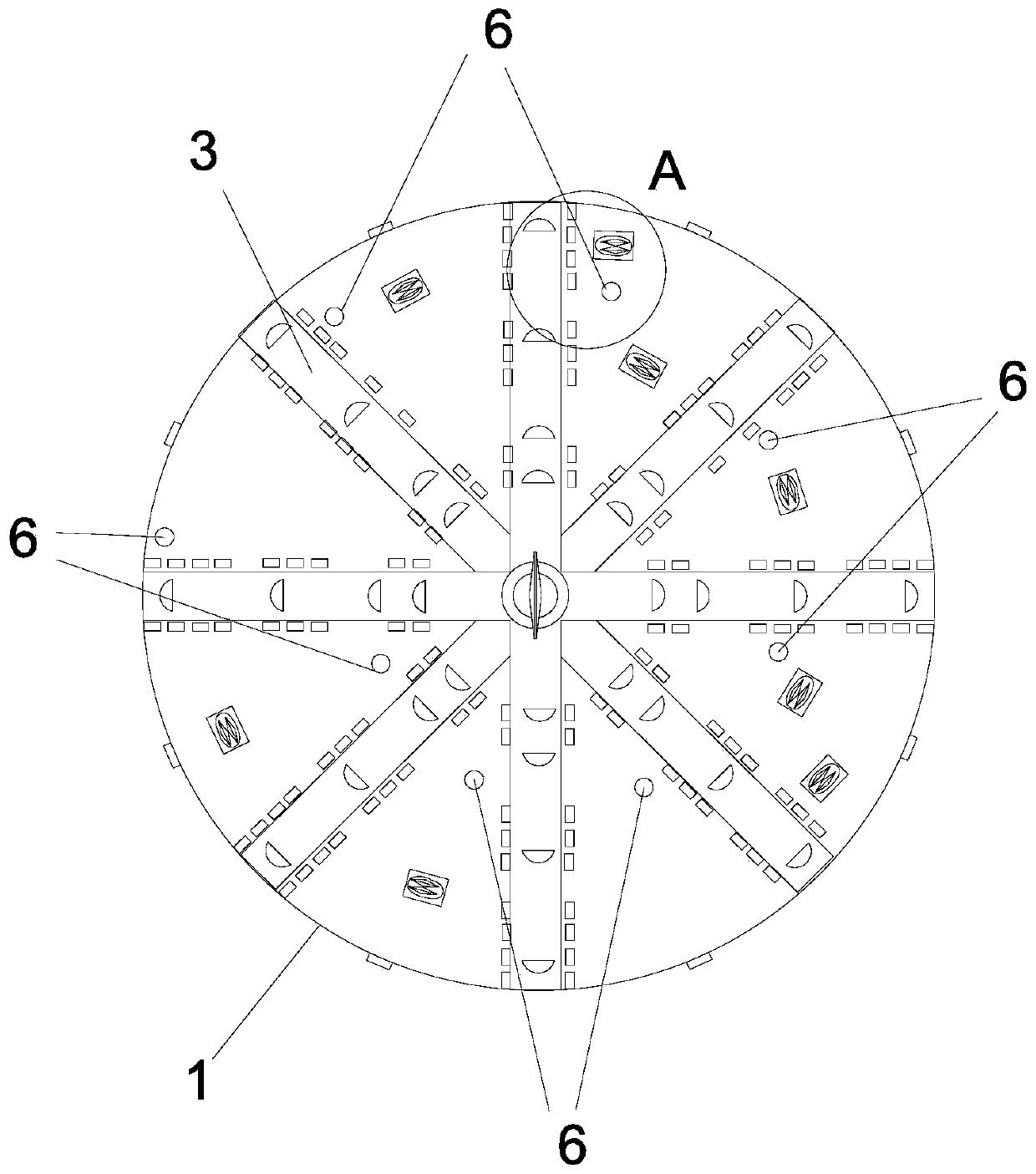

[0027] Such as figure 1 As shown, in embodiment one, a shield machine cutter head structure with a retractable geological drill includes a disc main body 1, a web plate 2 and spokes 3, and a peripheral knife 4 is provided on the circumference of the disc main body 1 for Cutting the rock and soil at the edge of the cutterhead, the spoke plate 2 is provided with a hob 21, which is used to press out circular indentations on the rock and soil, and generates lateral pressure to make the rock and soil continuously crack, and the spoke 3 is provided with a cutting knife 31. It is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com