Bearing cage segment including alignment element

A technology for bearing cages and cages, applied to bearings, bearing components, shafts and bearings, etc., can solve problems such as offset, no longer accurate alignment, segmental displacement of cages, etc., and achieve simple and reliable connection , the effect of stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

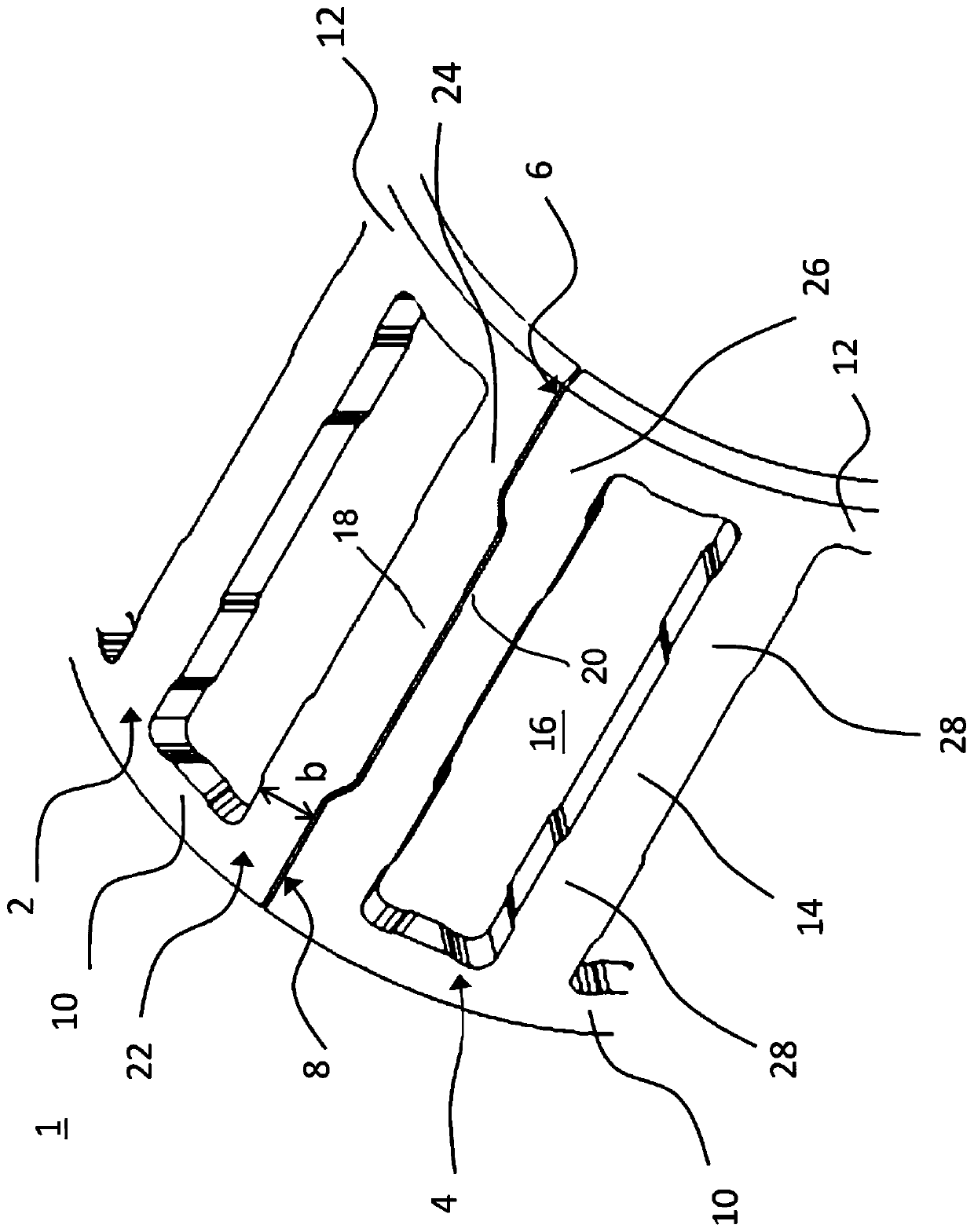

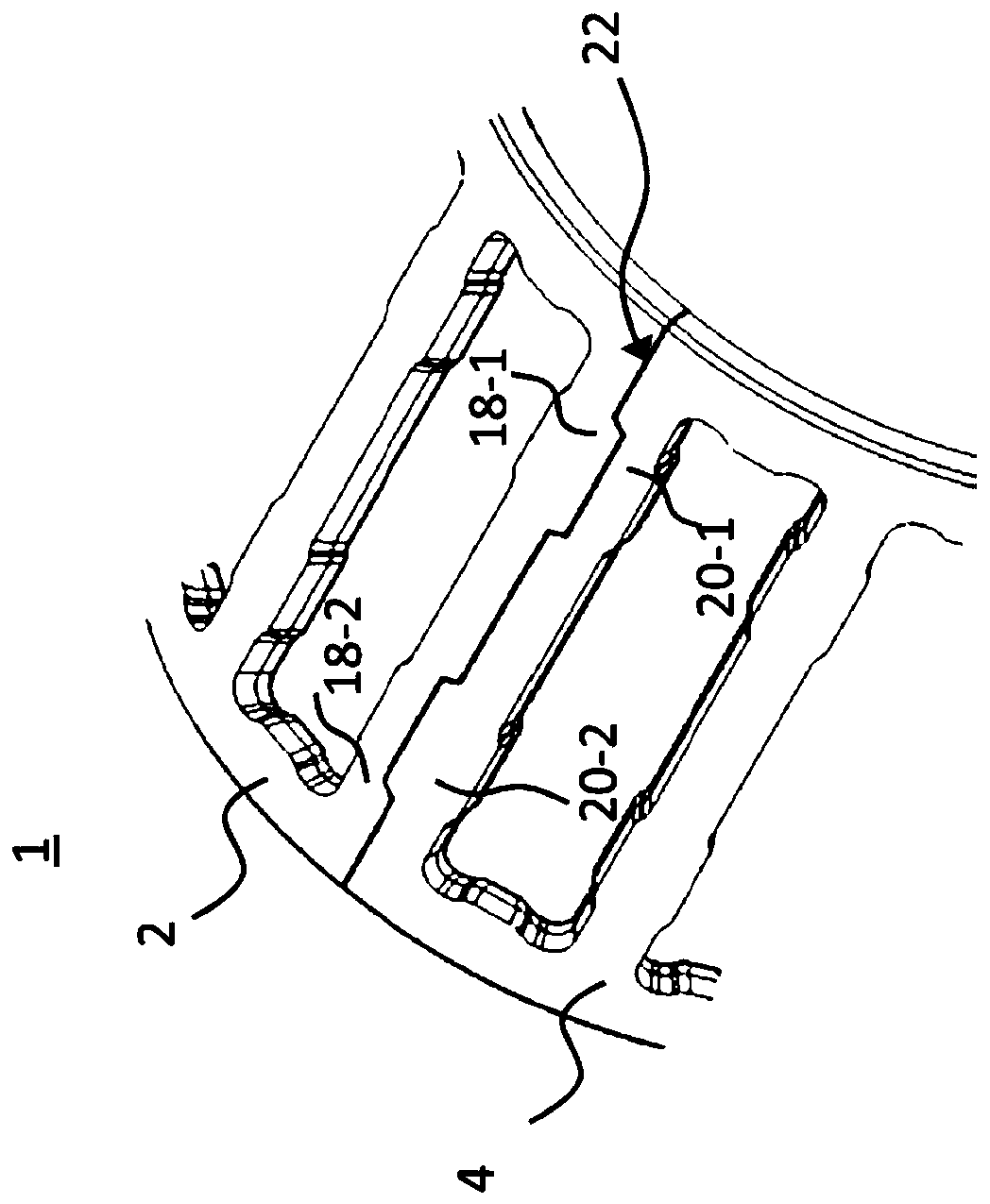

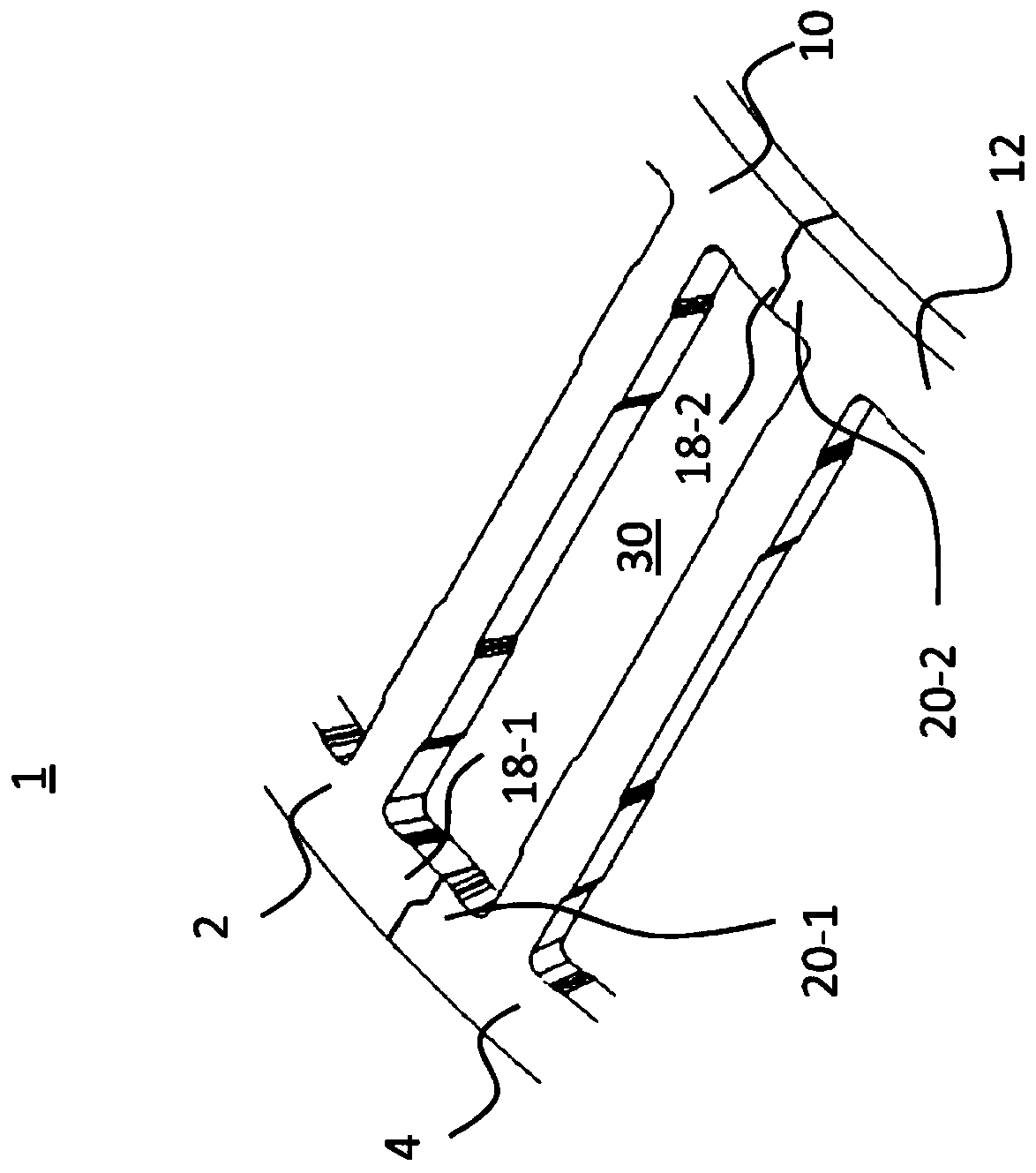

[0049] figure 1 Shows a detail view of a first exemplary embodiment of a sheet metal cage (sheet metal cage) 1 comprising a first bearing cage segment ( / segment / section) (segment) 2 and The second bearing cage segment 4 , the first bearing cage segment 2 and the second bearing cage segment 4 are arranged to abut each other at joint edges 6 , 8 , respectively. Here, instead of the first bearing cage segment 2 and the second bearing cage segment 4 , it is also possible to provide only a single bearing cage segment 2 , which comprises the joint edge 6 at the first end and the joint edge 6 at the second end. The edge of the joint at 8.

[0050] For the sake of simplicity it is assumed in the following that the metal cage comprises at least two bearing cage segments 2 , 4 abutting against each other.

[0051] Each bearing cage segment 2, 4 comprises a first ring part 10, a second ring part 12 and a plurality of bridges 14 connecting the first ring part 10 and the second ring part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com