Crushing and classifying method for light calcium carbonate

A light calcium carbonate, crushing and grading technology, applied in the direction of dyeing physical treatment, can solve the problems of harsh working environment, increased labor intensity, environmental pollution, etc., to avoid harsh working environment, reduce labor intensity, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

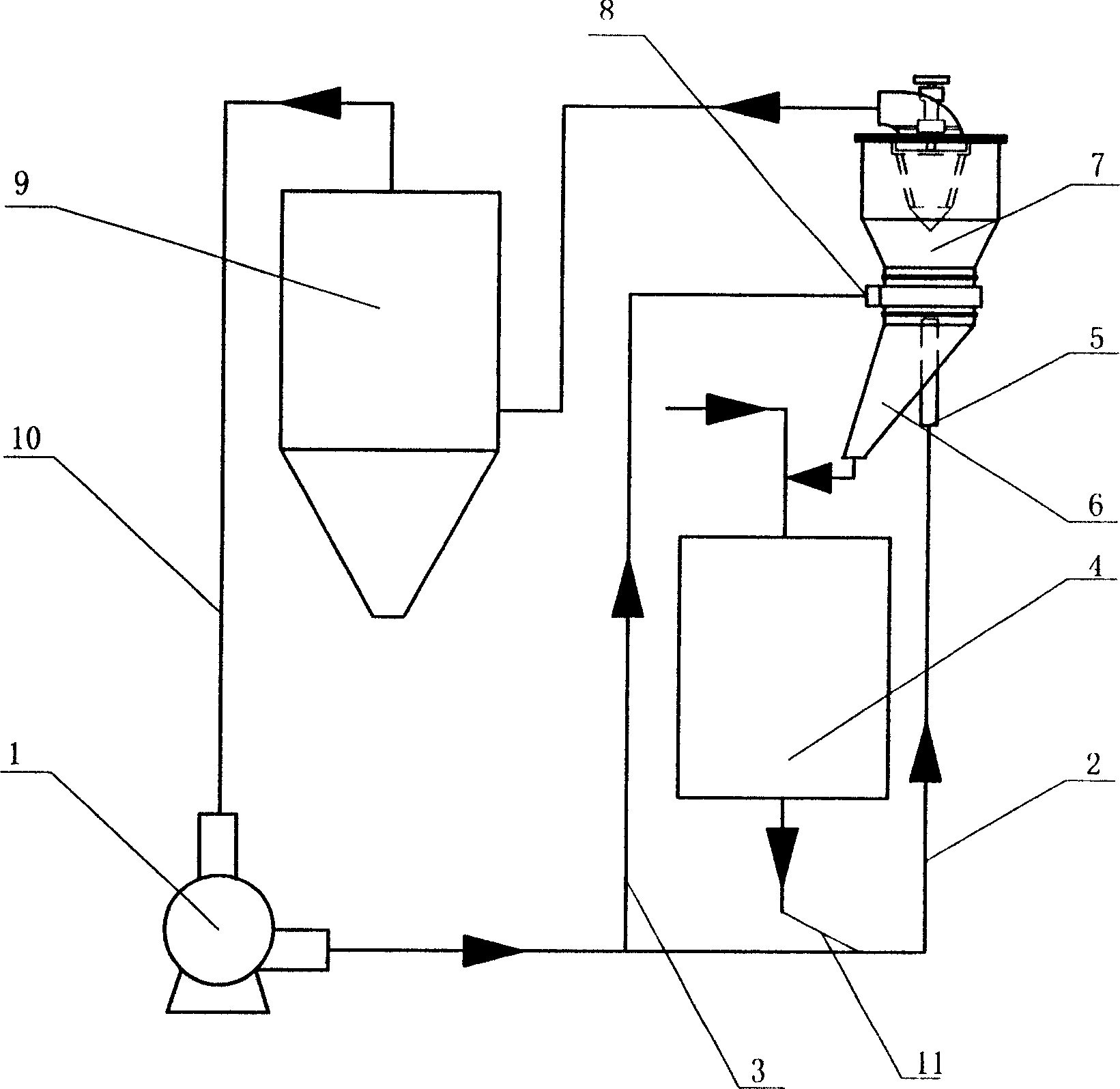

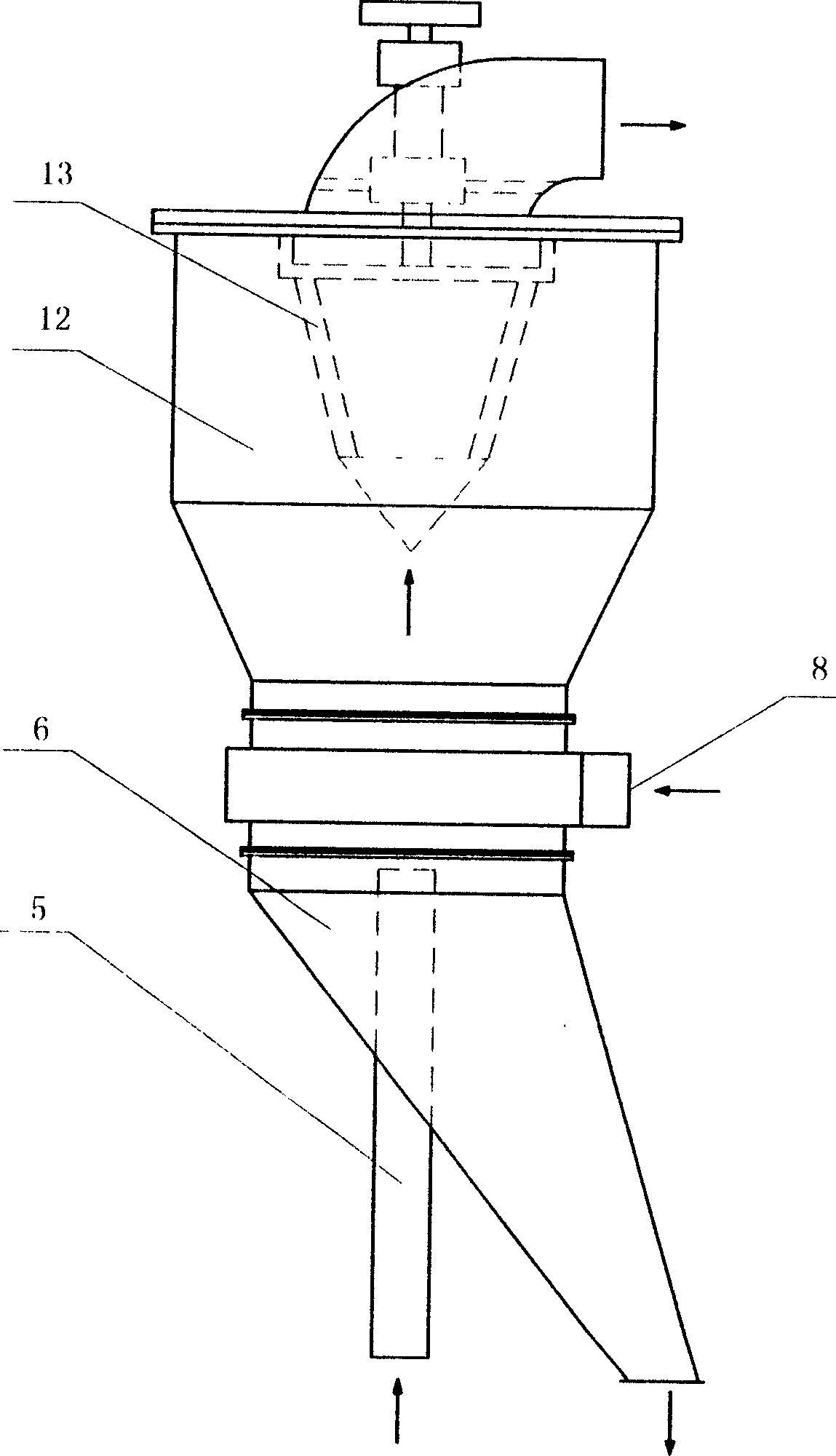

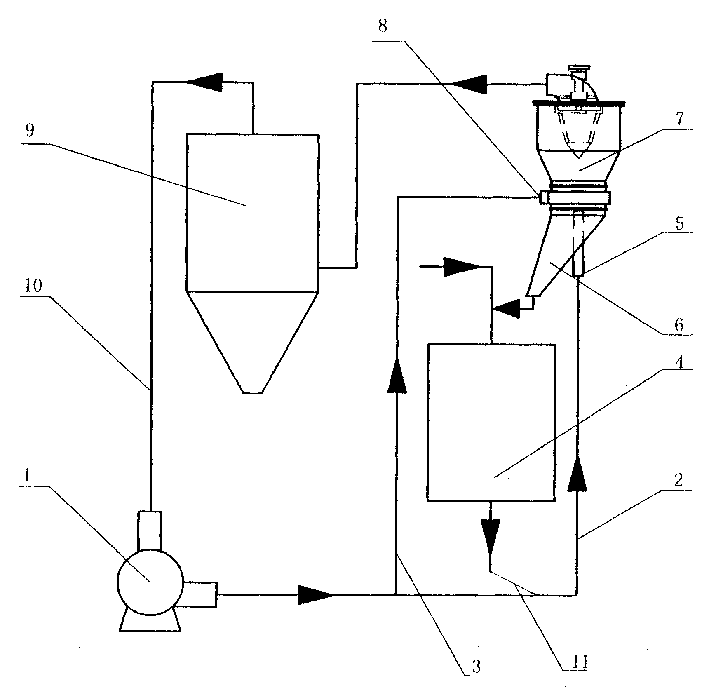

[0016] refer to figure 1 , The pulverizer, classifier, powder collection system and fan are connected into a closed-circuit system through pipelines, and the wind pressure generated by the fan is used as the power for material transportation. The air outlet of the powder collection system 9 is connected to the inlet of the fan 1 through the pipeline 10, the outlet of the fan 1 is connected to the material inlet 5 of the classifier 7 through the pipeline 2, and the outlet of the pulverizer 4 is connected to the outlet of the fan 1 and the outlet of the fan 1 through the pipeline 11. The pipeline 2 of the material inlet 5 of the classifier 7 is connected, so that when the airflow conveyed by the fan flows in the pipeline 2, the negative pressure generated at the junction of the pipeline 11 and the pipeline 2 makes the material transported from the pulverizer to the classifier 7; the pipeline 2 There is a pipeline 3 connected in parallel on the top, and one end of the pipeline 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com