Defrosting method and device for supercooling of refrigerant in refrigerating circulating main pipeline

A refrigeration cycle and refrigerant technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low cooling capacity, low return air pressure, waste of evaporation channel evaporation area, etc., to increase cooling capacity and reduce return The effect of gas superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

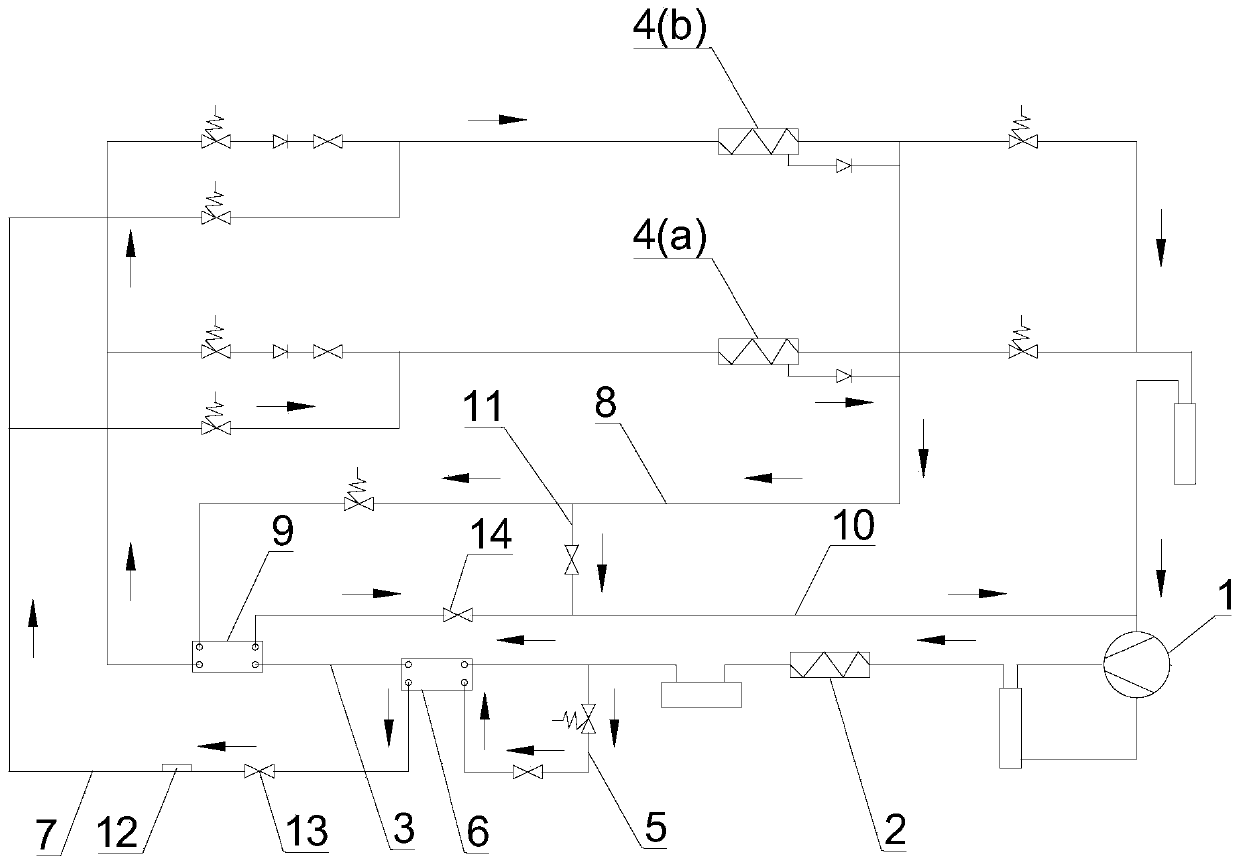

[0042] see image 3 , the defrosting device for subcooling the refrigerant in the main circuit of the refrigeration cycle in this embodiment is integrated in the refrigeration system, and includes a device for diverting the refrigerant in the main refrigeration pipeline 3 to the evaporator 4 (a) to be defrosted The defrosting pipeline 7, the main pipeline cooler 9 for subcooling the refrigerant in the main refrigeration pipeline 3, and the defrosting outlet pipeline 8 for transporting the defrosted refrigerant to the main pipeline cooler 9 And the loop pipeline 10 for sending the supercooled refrigerant back to the compressor 1; the defrosting pipeline 7 is connected to the refrigeration main pipeline 3; the head end of the defrosting liquid outlet pipeline 8 is connected to the At the outlet of the evaporator 4 (a) of the frost, the end is connected to the inlet of the main pipeline cooler 9; the head end of the loop pipeline 10 is connected to the outlet of the main pipeline...

Embodiment 2

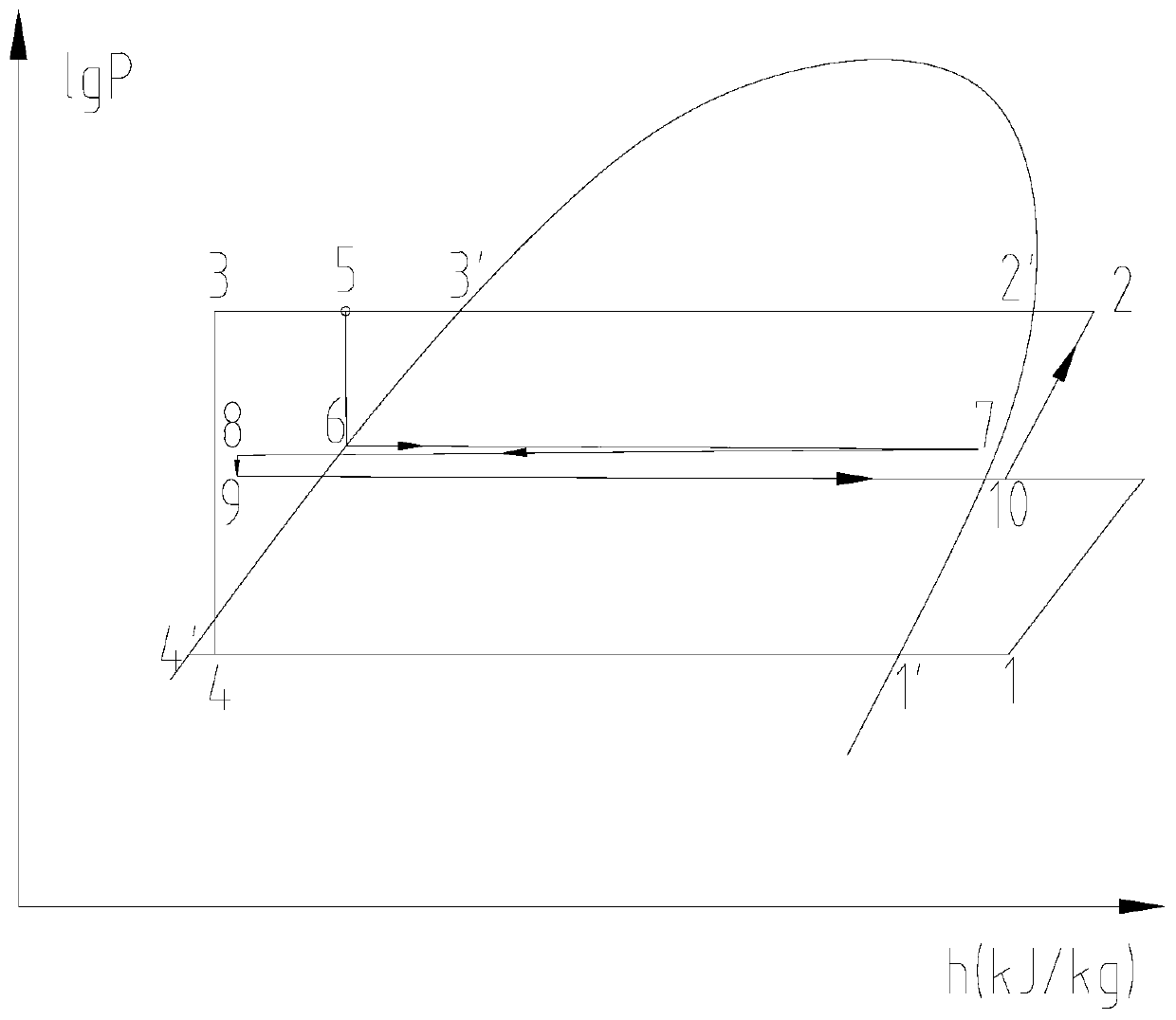

[0063] see figure 2 , the difference from Embodiment 1 is that in this embodiment, after supercooling, the liquid refrigerant absorbs heat and converts into gas refrigerant; the vapor-liquid mixture refrigerant is transported to the evaporating At device 4(a), the gas refrigerant is used as the defrosting medium to release heat and melt the frost on the evaporator.

Embodiment 3

[0065] Different from Embodiment 1, in this embodiment, when the refrigerant serving as the defrosting medium evaporates and absorbs heat for the first time and is used to cool the set refrigeration environment, energy utilization efficiency can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com