Non-destructive testing device and non-destructive testing method

A non-destructive testing technology to be tested, which is applied to measuring devices, instruments, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve problems such as equipment damage and affecting the performance of non-destructive testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

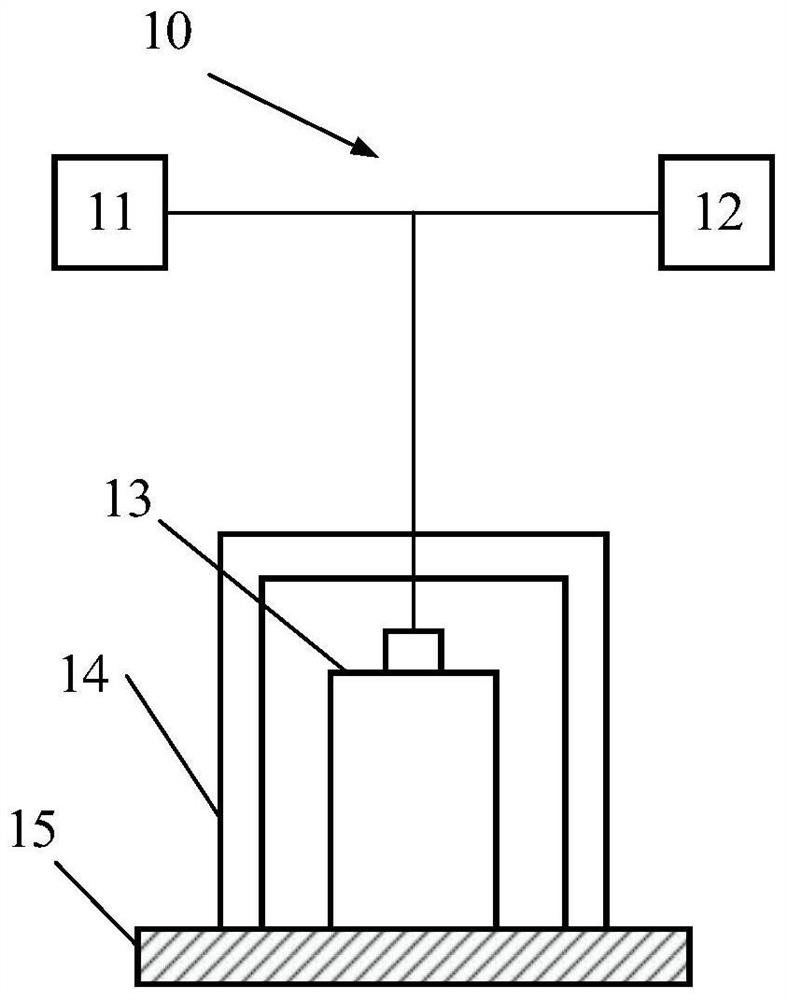

[0027] figure 1 is a schematic diagram of a non-destructive testing device according to an embodiment of the present invention.

[0028] An application scenario of the non-destructive testing device 10 according to the embodiment of the present invention is to perform non-destructive testing on the workpiece 15 to be tested (such as a superconducting magnet or a superconducting conductor), especially at a low temperature (for example, at a temperature of 4K to 200K ) for non-destructive testing.

[0029] Such as figure 1 As shown, the non-destructive testing device 10 according to the first embodiment of the present invention includes an excitation part 11 , a collection part 12 and a probe 13 , wherein both the excitation part 11 and the collection part 12 are connected to the probe 13 .

[0030] The "connection" mentioned in this article includes not only a physical wired connection, but also a direct or indirect, wired or wireless connection between two or more devices an...

no. 2 example

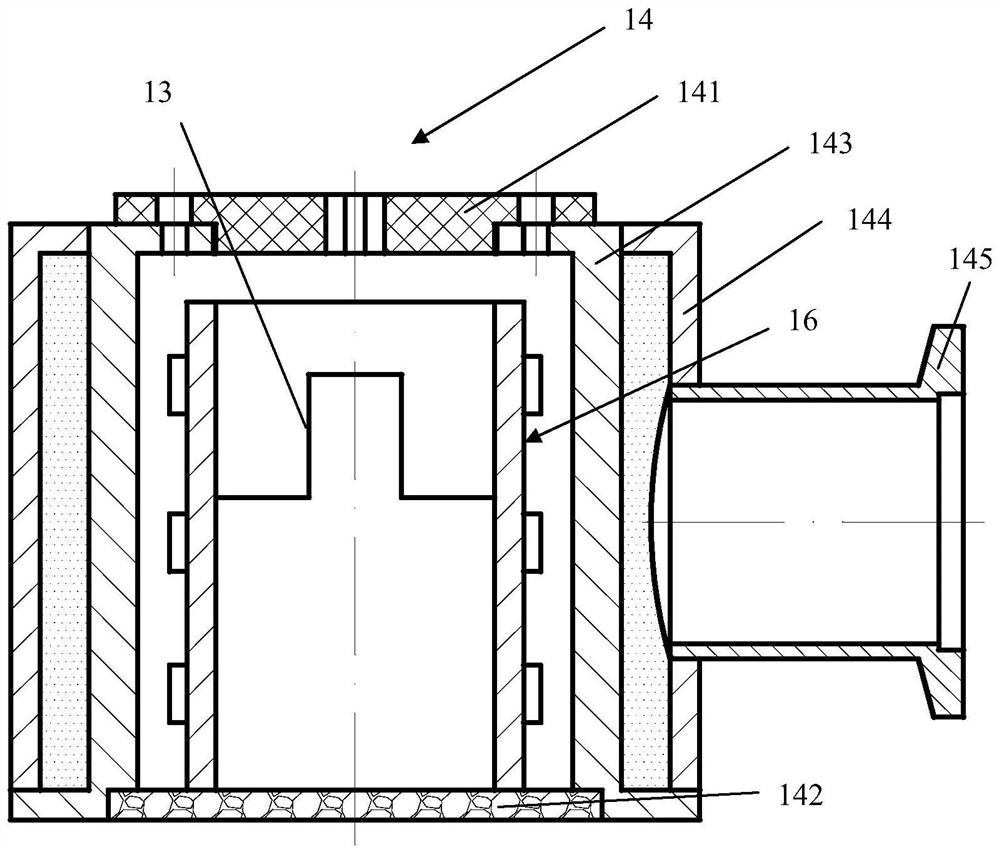

[0067] The second embodiment of the present invention will be described below with reference to the accompanying drawings.

[0068] The difference from the first embodiment is that the second embodiment of the present invention uses electromagnetic detection. In the following description, the same reference numerals are used for the same components as those of the first embodiment, and the description of the same or similar structures or functions as those of the first embodiment will be appropriately omitted to avoid unnecessary repetition.

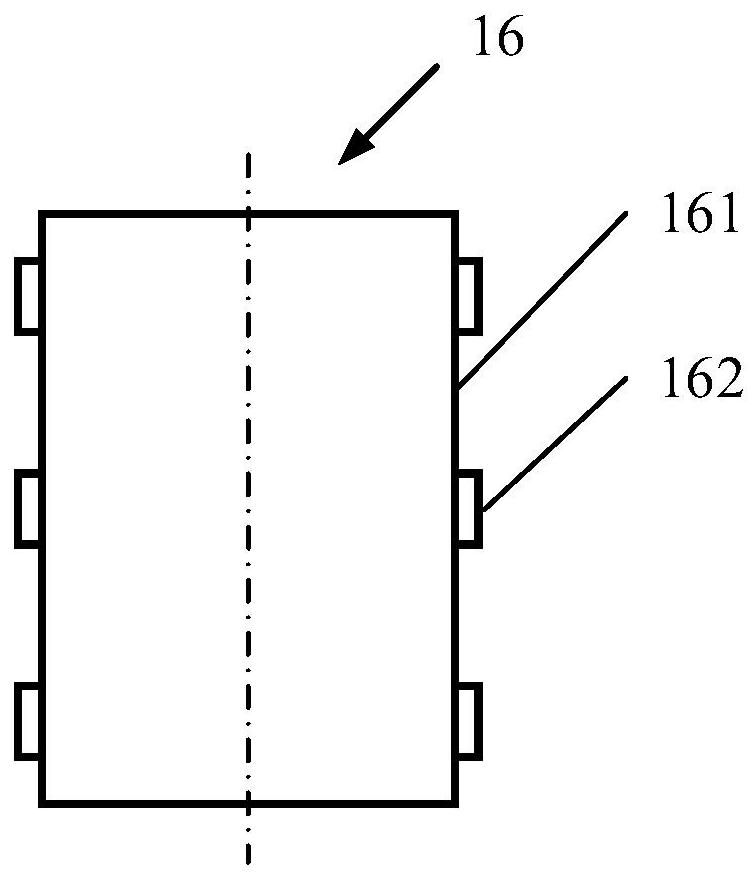

[0069] The non-destructive testing device 10 according to the second embodiment of the present invention includes an excitation part 11 , an acquisition part 12 and a probe 13 , wherein both the excitation part 11 and the acquisition part 12 are connected to the probe 13 . The second embodiment of the present invention adopts electromagnetic detection technology to realize non-destructive detection. The probe 13 is an electromagnetic prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com