Continuous side composite copper-aluminum composite material and manufacturing method thereof

A technology of copper-aluminum composite materials and manufacturing methods, which is applied in the direction of connection contact materials, cable/conductor manufacturing, connection, etc., can solve the problem of product quality consistency, difficulty in fully guaranteeing stability and reliability, insufficient ability to prevent crack expansion, copper The problems such as the small bonding area of the aluminum interface achieve the effects of easy non-destructive testing, good high-current over-current performance, and excellent anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

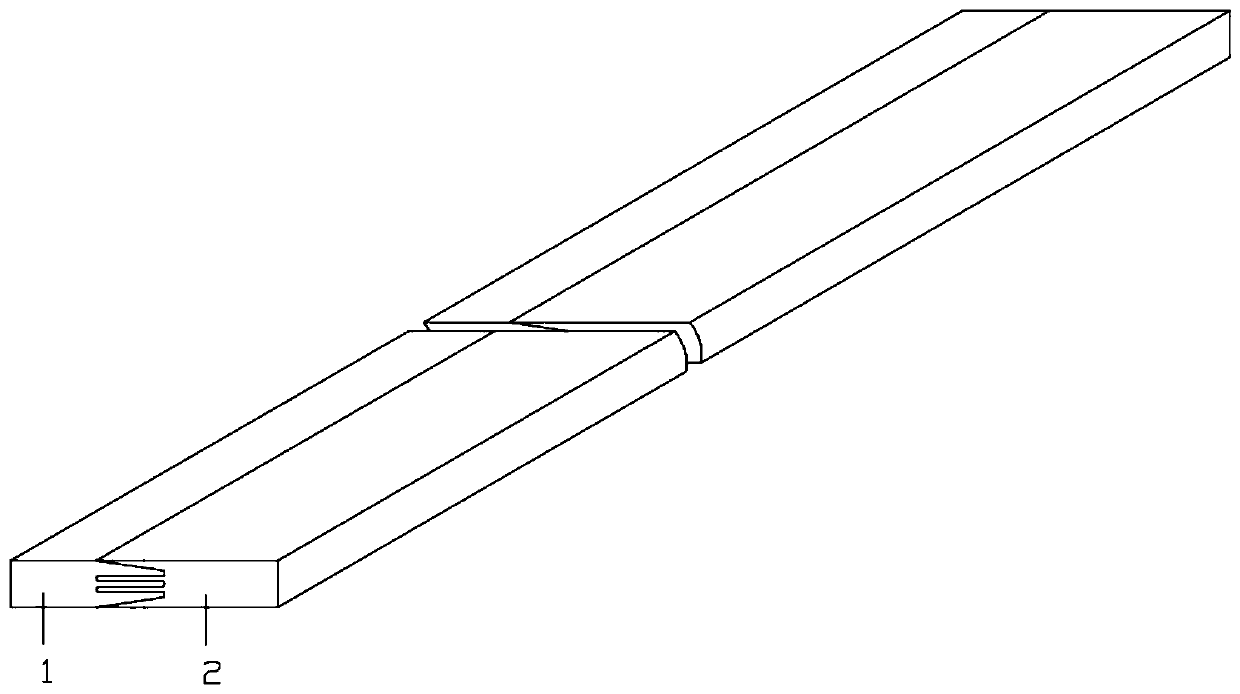

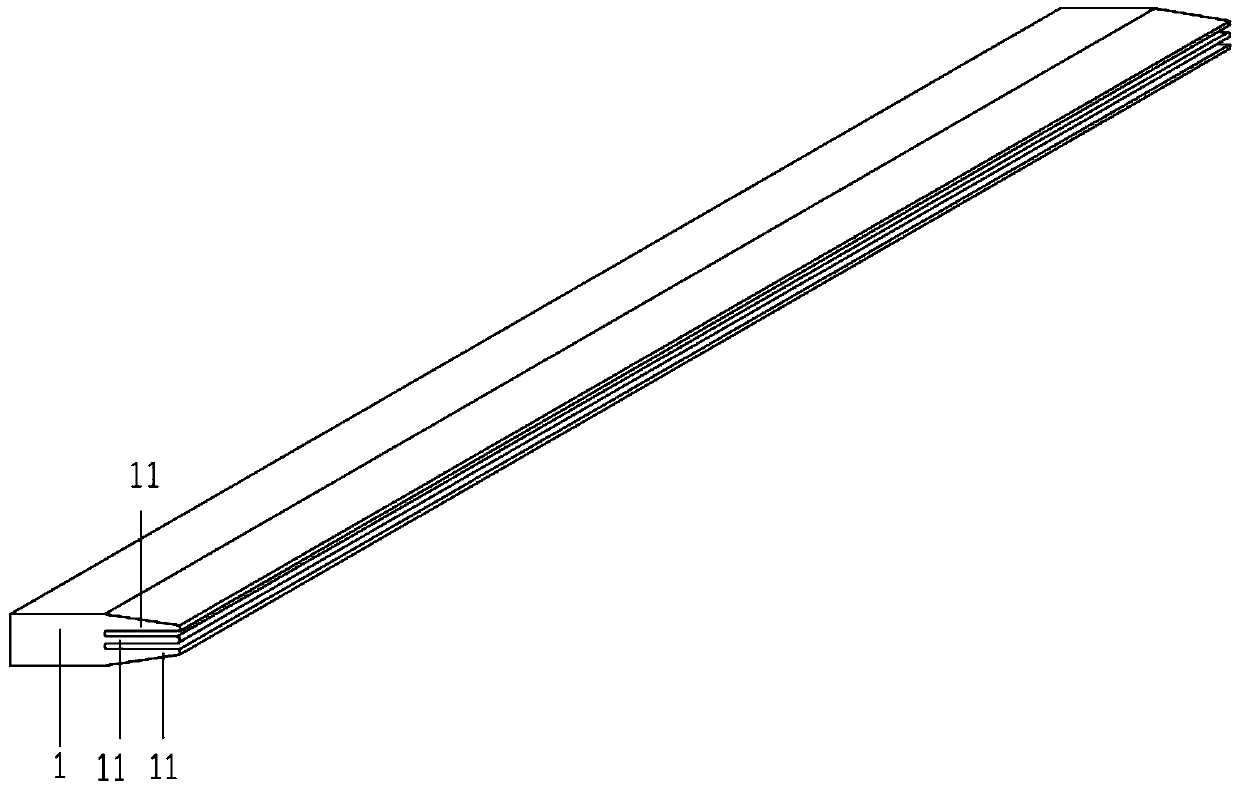

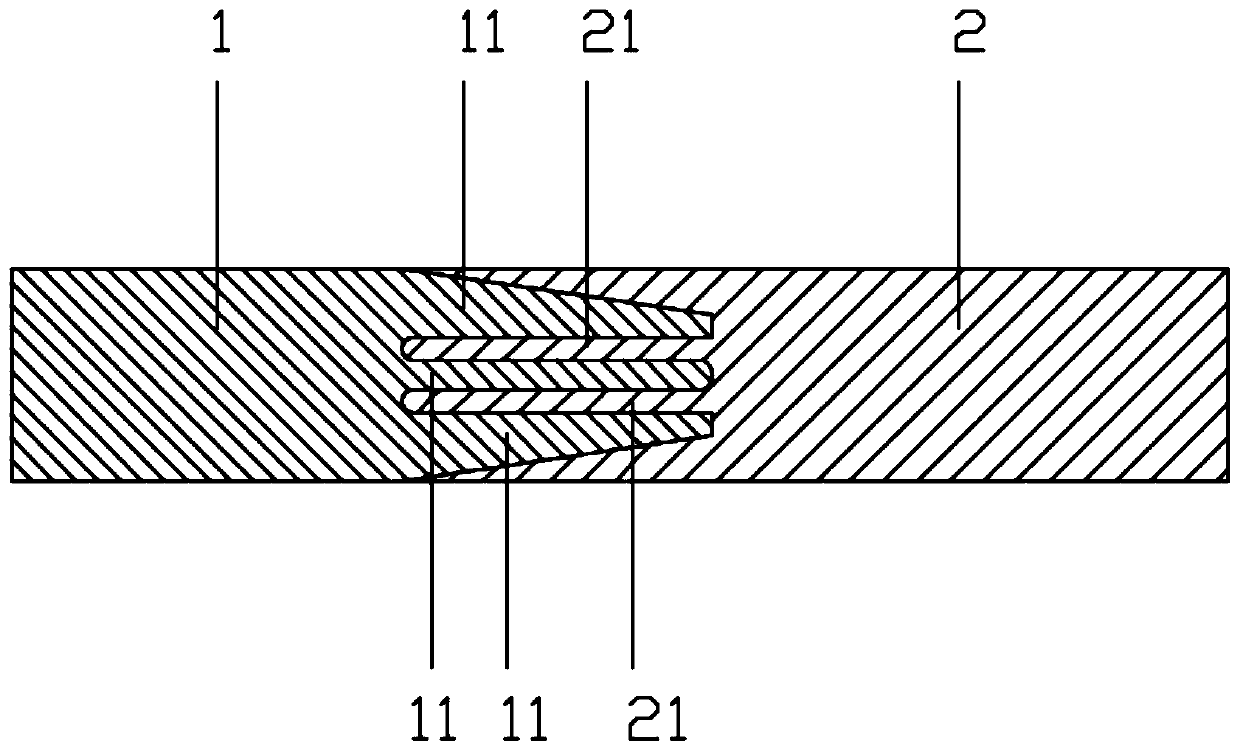

[0039] Such as Figure 1-5 As shown, the lateral composite copper-aluminum composite material disclosed in this embodiment includes a copper strip 1 and an aluminum strip 2, and one side of the copper strip 1 and one side of the aluminum strip 2 are made into a strip by three mortises. . In this embodiment, there are three mortises, which can double the area of the copper-aluminum interface bonding area, improve the bonding strength, and improve the stability.

[0040] In this embodiment, one side of the aluminum strip 2 is provided with an aluminum tenon groove 22 along its length direction, and the aluminum tenon groove 22 runs through the two ends of the aluminum strip 2. There are three copper tenons 11 adapted to the aluminum tenons 22 , and the three copper tenons 11 are installed in one of the aluminum tenons 21 respectively. Of course, the length of the copper tenon 11 is equal to the length of the copper strip 1 . Two aluminum tenons 21 are formed between the thr...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that: Figure 8 , 9 As shown, in this embodiment, the aluminum tenon 21 is thickened at the head end, and the copper tenon 12 is narrowed at the notch. Preferably, the aluminum tenon 21 is gradually thickened from the root to the head, and the copper tenon 12 is gradually narrowed from the bottom to the notch. This structure can effectively prevent copper and aluminum tenons from loosening, suppress possible crack propagation, and improve reliability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com