A method for forming large-diameter bellows expansion joints

A forming method and corrugated pipe technology, which is applied to expansion compensation devices for pipelines, pipe elements, pipes/pipe joints/pipe fittings, etc., can solve problems such as bellows scratches, and achieve scratch prevention, weld quality and Good appearance, easy installation and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

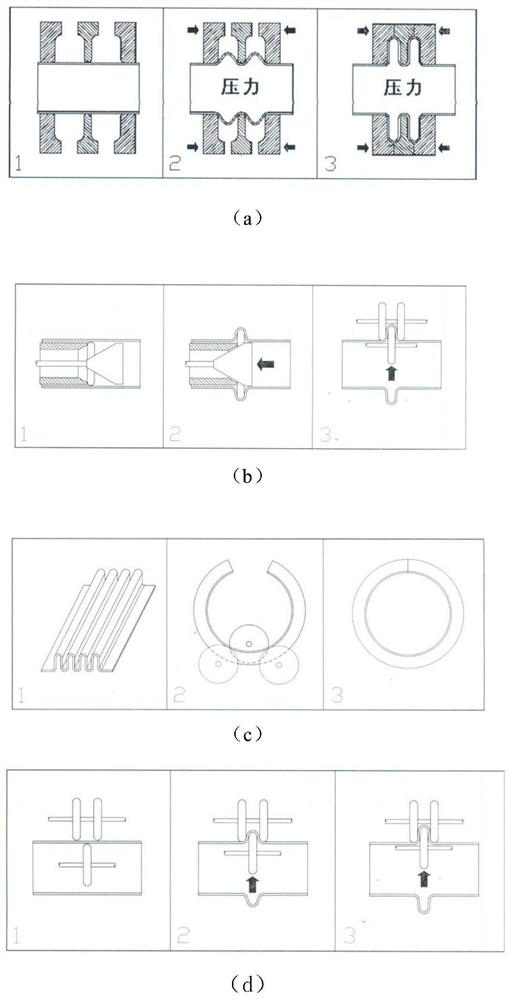

[0026] The present invention will be further described below in conjunction with the accompanying drawings:

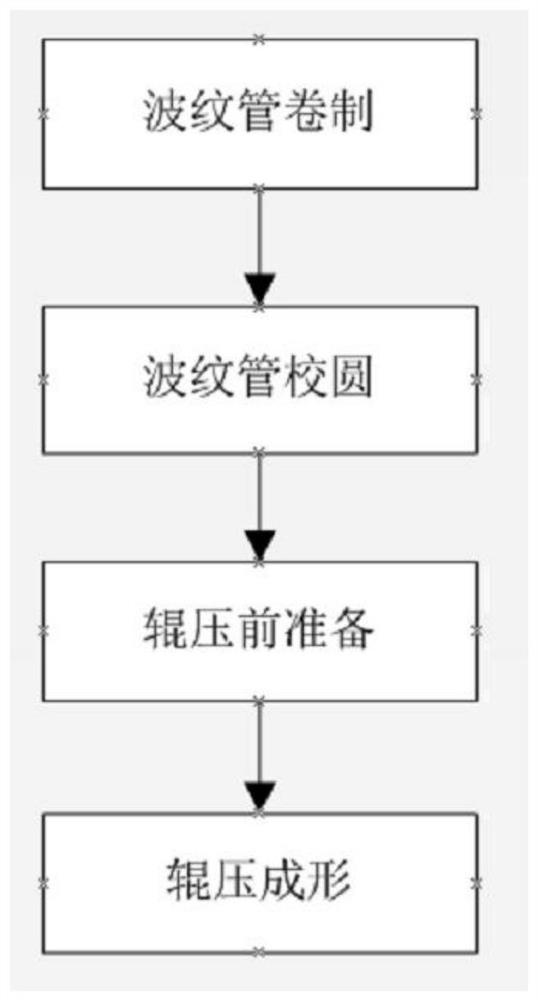

[0027] like figure 1 As shown, the present invention discloses a method for forming a large-diameter bellows expansion joint, comprising the following steps:

[0028] Step 1, the rolling of the corrugated pipe, because the diameter of the trial production corrugated pipe is 15 meters, the diameter of the large-diameter corrugated pipe is larger, the length of the plate determines that the direct rolling cannot be realized, and it needs to be rolled in sections, and the steel plate is rolled in a three-roller coil. It is carried out on the plate machine. When rolling, first of all, pay attention to the alignment of the steel plate when it enters the plate bending machine to prevent it from being rolled into an ellipse. Before rolling, clean up the dust and oxide scale on the plate bending machine in time to prevent the repeated rolling process. The surface of the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com