Offshore supply system and method

A supply system and supply ship technology, applied in the field of supply at sea, can solve the problems of inability to meet the needs of picking and placing goods, inconvenient adjustment and expansion of supply boxes, and difficulty in disassembly and maintenance, and achieves simple structure, convenient picking and placing, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

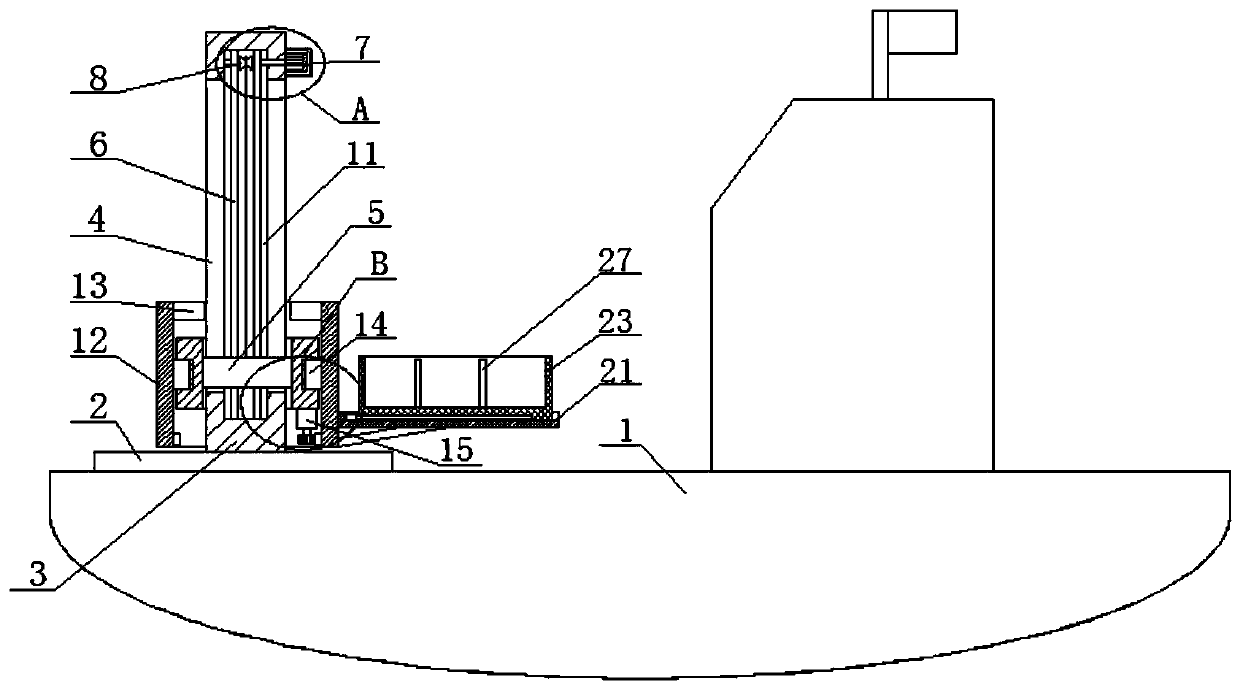

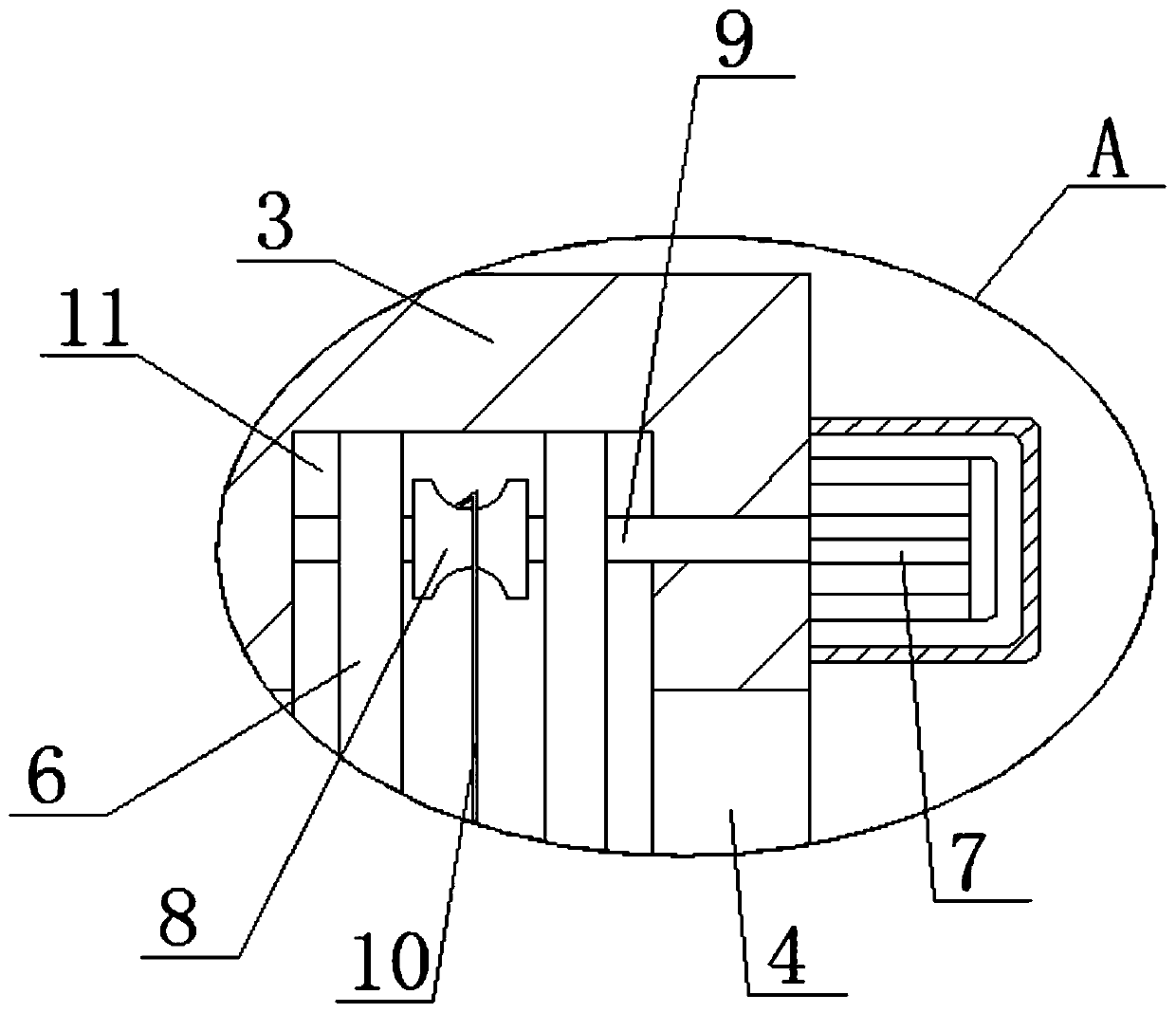

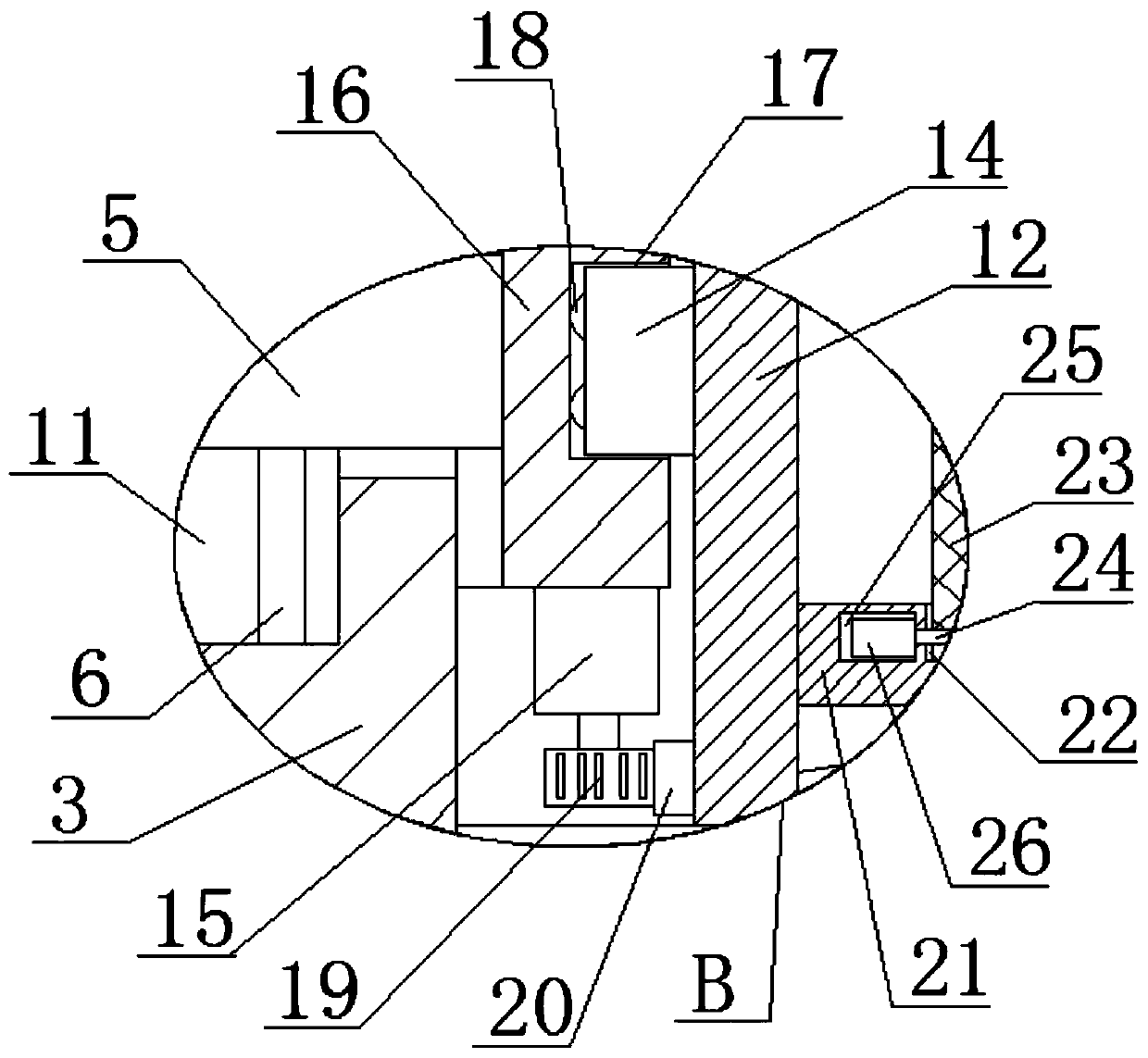

[0045] refer to Figure 1-5 , a marine replenishment system, comprising a supply ship 1 and a supply box 23, the interior of the supply box 23 is provided with a plurality of supply partitions 27, the top of the supply ship 1 is fixedly connected with a placement seat 2 by screws, and the top of the placement seat 2 is fixed by screws A column 3 is fixedly connected, and a cavity 11 is provided on the column 3. Two symmetrical holes 4 are provided on the inner wall of the cavity 11. The same connecting rod 5 is slidably installed in the two symmetrical holes 4. The column 3 is provided with a The lifting structure, the lifting structure and the connecting rod 5 are fixedly connected by screws, the two ends of the connecting rod 5 are fixedly installed with the same welding ring 16 by welding, the outer side of the welding ring 16 is rotated and installed with a supporting outer ring 12, and the inner wall of the supporting outer ring 12 The shielding ring 13 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com