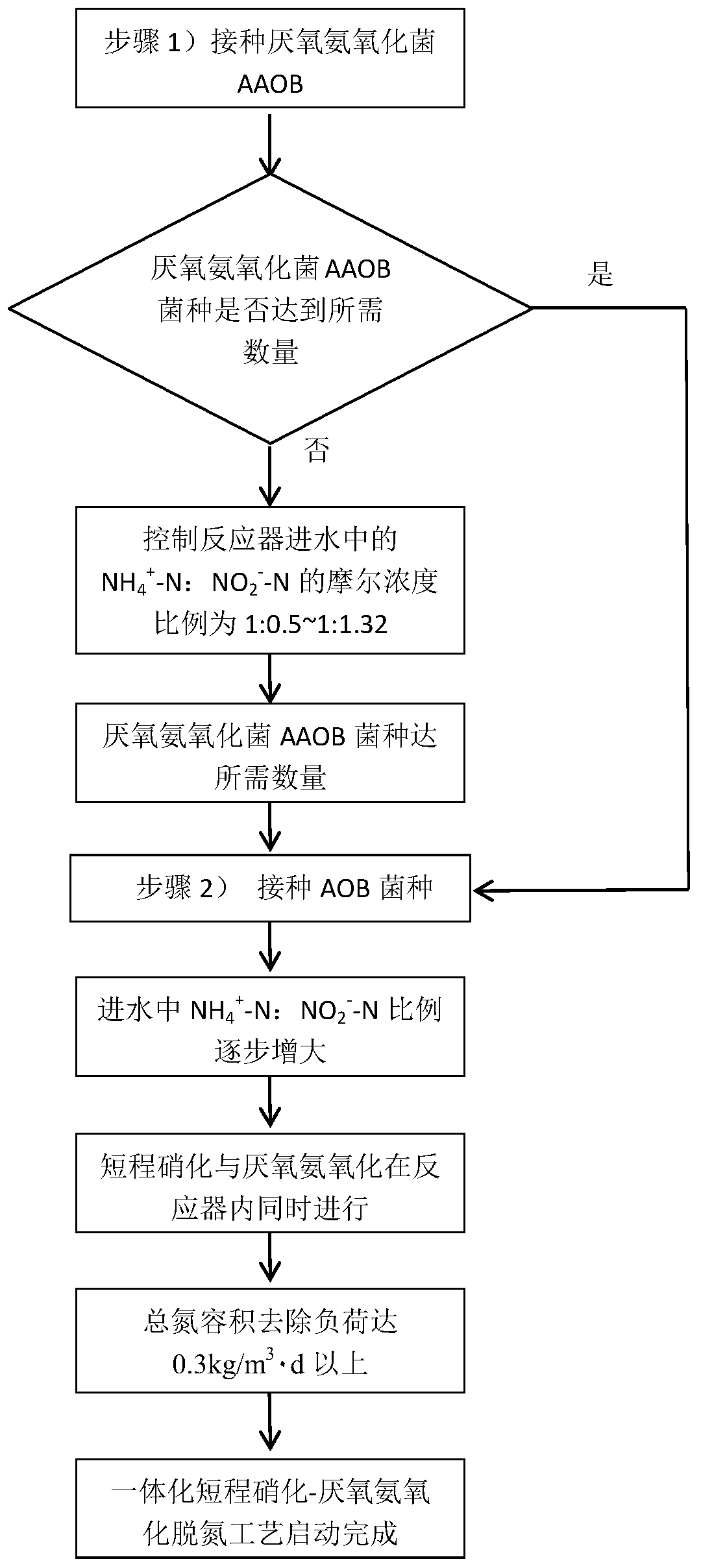

Starting method of integrated short-cut nitrification-anaerobic ammonia oxidation de-nitrification process

A technology of anammox and anammox bacteria is applied in the start-up field of an integrated short-range nitrification-anammox denitrification process, which can solve the problem of low yield, easy loss, and AAOB enrichment of anammox bacteria Difficulties and other problems, to achieve the effect of simple and fast process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

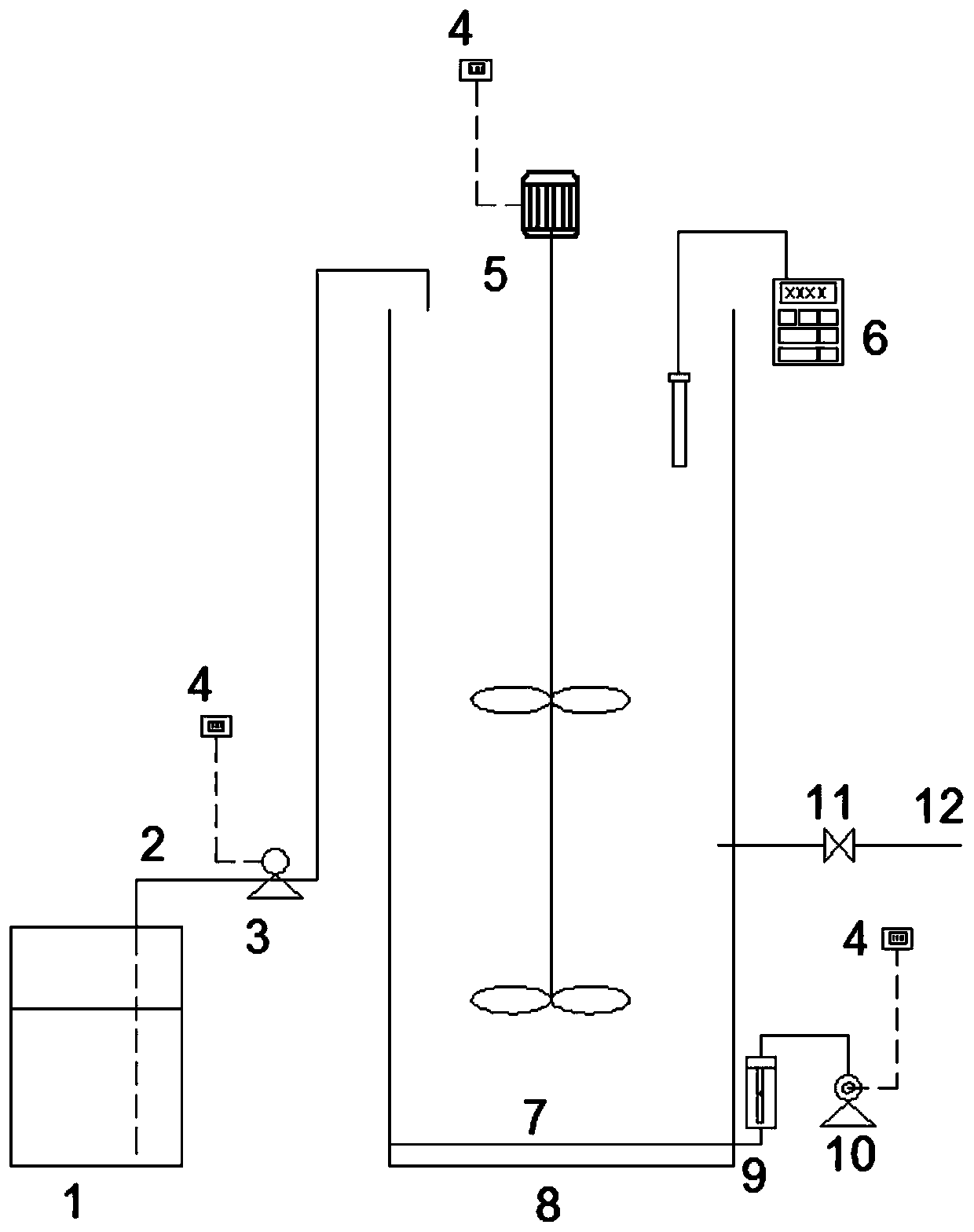

[0045] Turn on the mechanical stirring device (5) and continue to stir; turn on the water inlet pump (3) to feed water. The principle of water inlet is to control the NO in the reactor. 2 - -N≤80mg / L, to avoid the inhibition of nitrous on the anaerobic ammonium oxidizing bacteria AAOB bacteria; until the influent level reaches a high level, turn off the influent pump (3), and the accumulated water inflow is 3 cubic meters each time; then anaerobic Stir for 60min, turn off the mechanical stirring device (5); start the blower (10), the air is supplied to the aeration device (7) through the gas flow meter (9), and the dissolved oxygen in the reactor is monitored by the DO measuring instrument (6), Control reactor DO=0.2mg / L, continuous aeration, realize short-range nitrification under low dissolved oxygen conditions, and at the same time carry out anaerobic ammonium oxidation reaction, and the reaction is carried out continuously without intermittent.

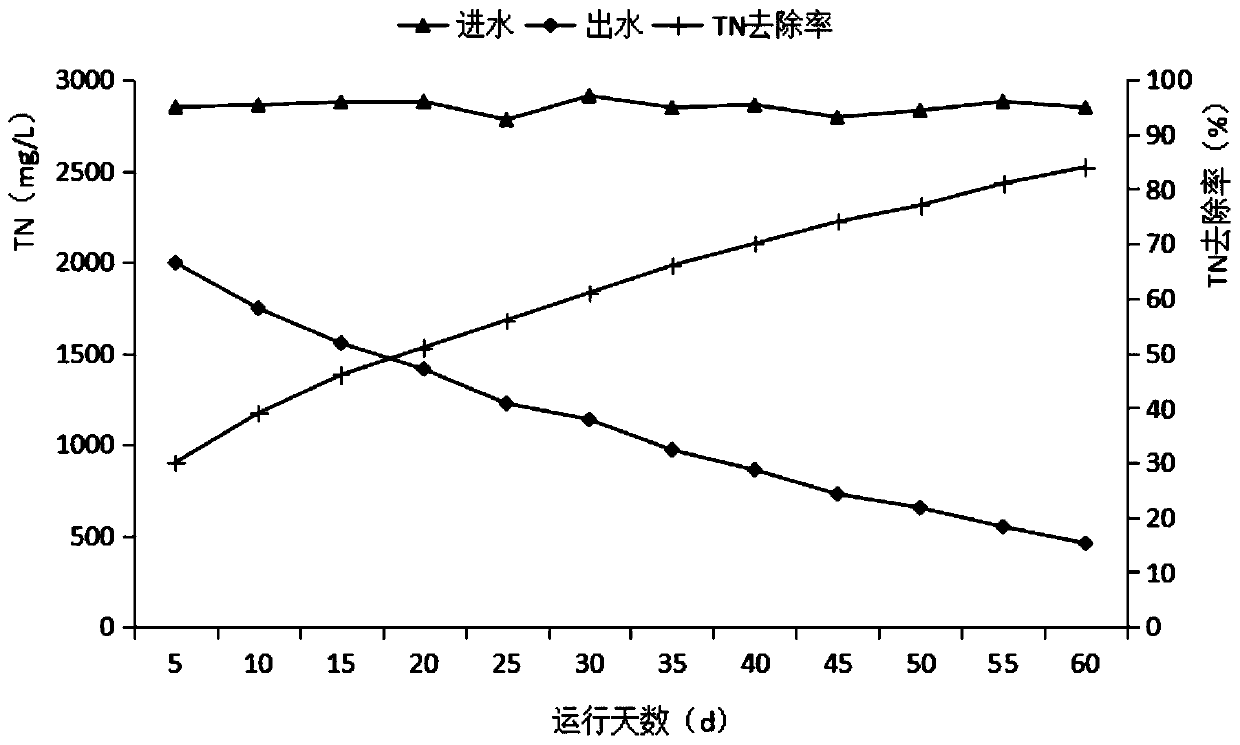

[0046] When reactor disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com