Automatic mushroom liquid strain injection machine

A liquid strain, automatic injection technology, applied in the field of injection machines, can solve problems such as low injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

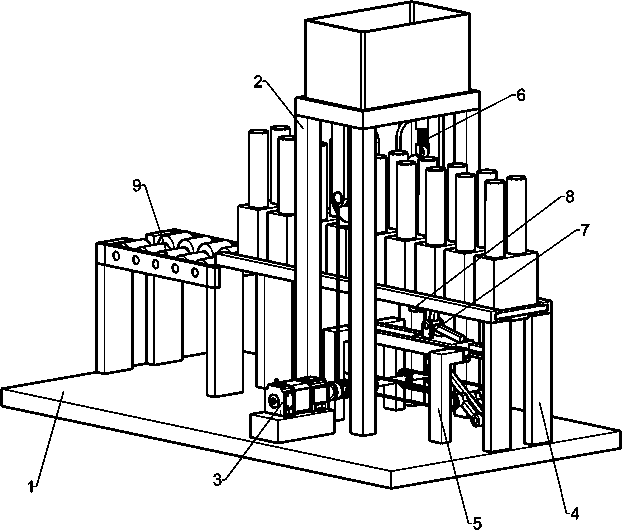

[0041] A kind of automatic injection machine for mushroom liquid spawn, such as figure 1 As shown, it includes a base 1, a first support 2, a motor 3, a second support 4, a third support 5, an infusion mechanism 6 and an intermittent feeding mechanism 7, the middle part of the right side of the base 1 is provided with the first support 2, and the base 1 A motor 3 is installed on the front side of the right, and the motor 3 is located directly in front of the first support 2. A second support 4 is arranged between the left and right sides of the base 1. The second support 4 is located below the first support 2. The right side of the base 1 is equipped with a The third support 5, the third support 5 is located below the second support 4, the output shaft of the first support 2 and the motor 3 is provided with an infusion mechanism 6, the parts of the infusion mechanism 6 and the third support 5 and the second support 4 Intermittent feeding mechanism 7 is installed between.

[0...

Embodiment 2

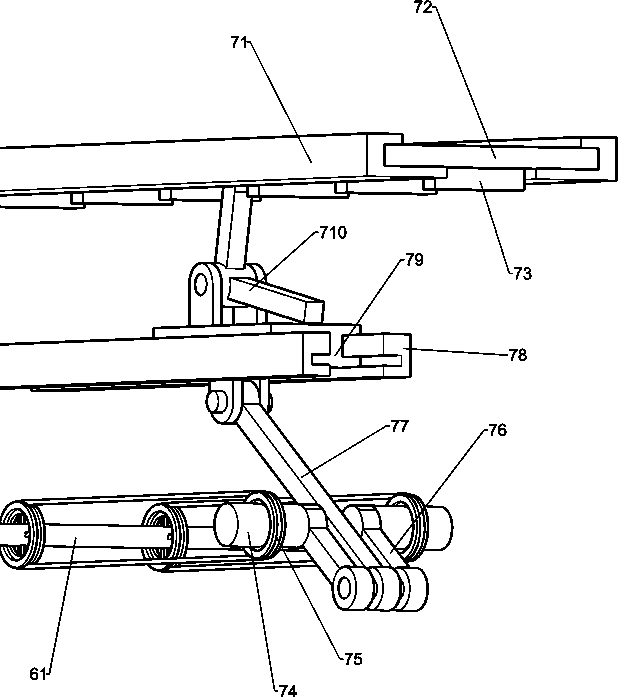

[0044] In particular, refer to Figure 1-4As shown, the infusion mechanism 6 includes an output shaft 61, a first shaft 62, a first belt assembly 63, a cam 64, a liquid bacteria storage box 65, a cylindrical sliding sleeve 66, a liquid injection pipe 67, a moving water pipe 68, and a first spring 611 With the first roller 612, the output shaft 61 is installed on the output shaft of the motor 3, and the first shaft 62 is provided with the first shaft 62 in the front and rear sides of the first support 2 top. The first belt assembly 63 is connected between the two parts, the inboard of the first rotating shaft 62 is equipped with a cam 64, the top of the first support 2 is provided with a liquid spawn storage box 65, and the front and rear sides of the liquid spawn storage box 65 bottom are A cylindrical sliding sleeve 66 is provided, and a moving water pipe 68 is slidingly installed in the cylindrical sliding sleeve 66. The inner side of the lower part of the moving water pipe ...

Embodiment 3

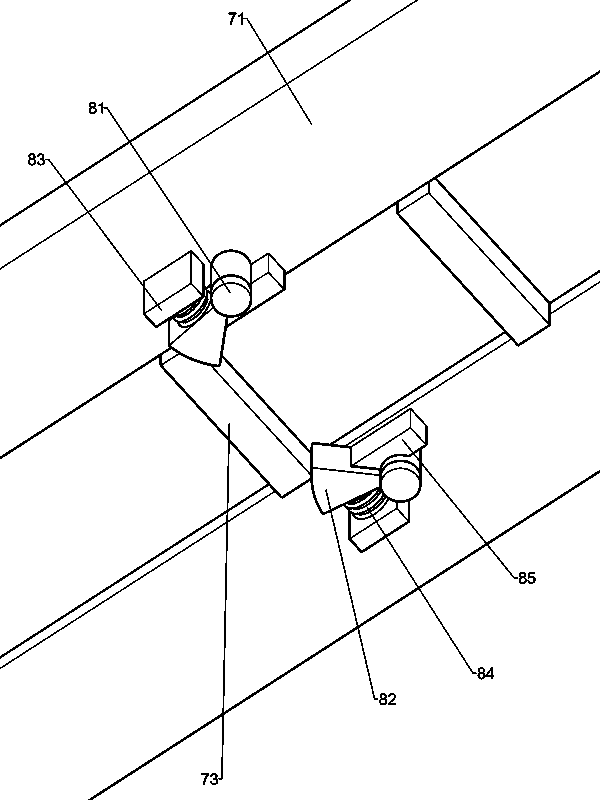

[0049] according to figure 1 with Figure 5-6 As shown, a fixing mechanism 8 is also included. The fixing mechanism 8 includes a support shaft 81, a fixing block 82, a mounting plate 83, a second spring 84 and a baffle plate 85, and the right side of the bottom of the first slide rail 71 on both sides is provided with a support Shaft 81, the bottom of the first slide rail 71 between the support shafts 81 on both sides is provided with a baffle plate 85, the bottom of the first slide rail 71 on the left side of the support shaft 81 is connected with a mounting plate 83, and the mounting plates 83 on both sides are close to each other Second spring 84 is installed on the side of each side, on the support shaft 81, the fixed block 82 is connected in rotation, the end of the second spring 84 is connected with the fixed block 82, and the fixed block 82 cooperates with the block 73.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com