A method of improving double-zero aluminum foil annealing heat drum

A double-zero aluminum foil, fiery technology, applied in the field of aluminum processing, can solve the problems of large investment and great impact on efficiency, and achieve the effect of reducing the annealing heat drum, effectively improving the effect, and improving the heat drum problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] The production specification thickness*width*length is 0.0063mm*1420mm*48200m and the order is 52 volumes in total, of which 26 volumes are produced using the elaboration method of the present invention, and the other 26 volumes are not lengthened.

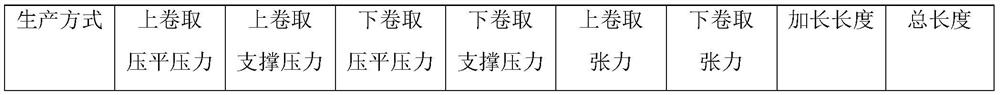

[0037] Parameter comparison table when cutting

[0038]

[0039]

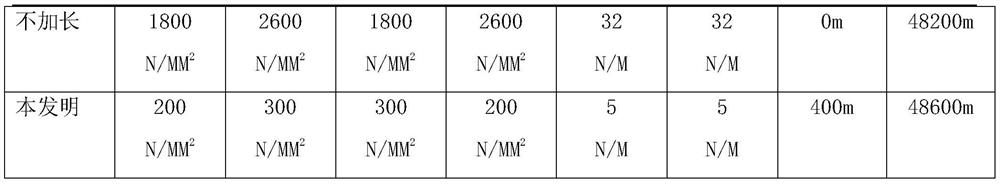

[0040] Comparison table of thermal drum conditions during packaging

[0041]

[0042] Through the comparison of the lengthened and non-lengthened aluminum coils of Example 1, the aluminum foil produced by the method of the invention has a lower heat drum generation ratio of 81.2% and a final scrap rate of 5.9% lower.

example 2

[0044] The production specification thickness*width*length is 0.006mm*1240mm*36000m and the order is 60 rolls in total, of which 28 rolls are produced by using the elaboration method of the present invention, and the other 32 rolls are produced by using normal parameters to lengthen the production.

[0045]

[0046] Comparison table of thermal drum conditions during packaging

[0047]

[0048] The comparison between the normal parameters of Example 2 and the lengthening of the parameters of this method proves that the aluminum foil produced by the method of the invention has a 79.5% lower heat drum generation ratio and a 3.2% lower waste rate eventually.

example 3

[0050] The production specification thickness*width*length is 0.006mm*1040mm*12200m and the order is 126 rolls in total, 40 rolls of which are produced using the elaboration method of the present invention, 40 rolls are produced using normal parameters for lengthening, and the other 46 rolls are not lengthened.

[0051] Parameter comparison table when cutting

[0052]

[0053] Comparison table of thermal drum conditions during packaging

[0054]

[0055] The comparison of Example 3 proves that the aluminum foil produced by the method of this invention has the lowest rate of occurrence of hot drums and the generation of final waste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com