Novel fabricated box culvert and construction method thereof

A construction method and prefabricated technology, which is applied in the direction of infrastructure engineering, buildings, road bottoms, etc., can solve the problems of many connection parts, a large number of box culverts, and difficult construction, so as to facilitate waterproofing, ensure connection quality, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

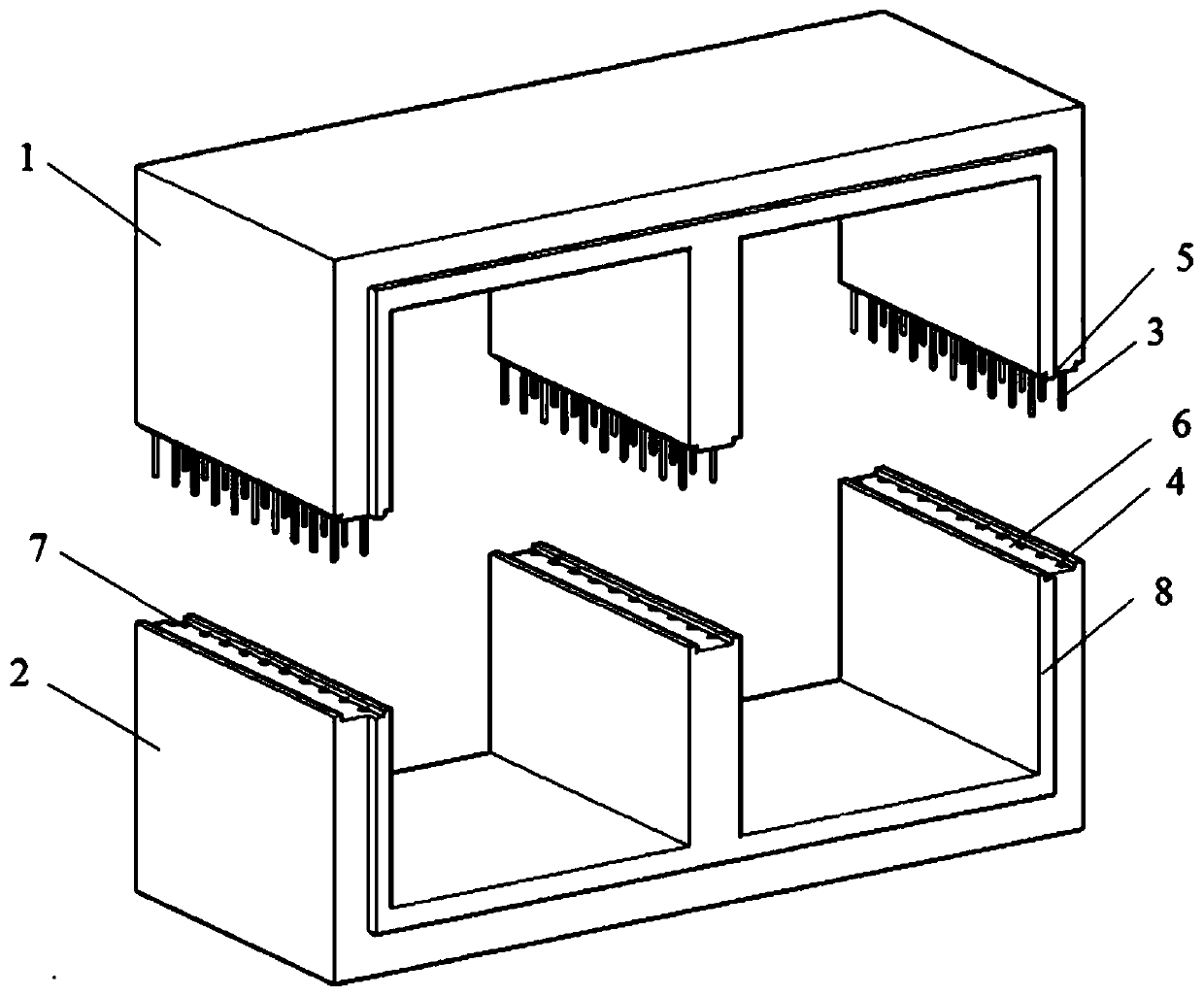

[0032] see figure 1 , a new type of assembled box culvert, mainly composed of an upper box culvert 1 and a lower box culvert 2, the upper box culvert 1 is provided with a plurality of vertical steel bars 3, and the vertical steel bars 3 protrude in the vertical direction Outside the upper box culvert 1; inside the lower box culvert 2 are provided a plurality of steel sleeves 4 adapted to the vertical steel bars in the upper box culvert.

Embodiment 2

[0034] see Figure 2-3 , a new type of assembled box culvert, mainly composed of an upper box culvert 1 and a lower box culvert 2, the upper box culvert 1 is provided with a plurality of vertical steel bars 3, and the vertical steel bars 3 protrude in the vertical direction Outside the upper box culvert 1; inside the lower box culvert 2 are provided a plurality of steel sleeves 4 adapted to the vertical steel bars in the upper box culvert.

[0035] Wherein, each section of the box culvert is provided with a longitudinal notch 7 along one end of the vertical direction, and the opposite end is provided with a longitudinal convex notch 8, and the longitudinal notch 7 and the longitudinal convex notch 8 are adapted to each other; The protrusion 8 fits with the longitudinal notch (7) and forms a cavity 9; waterproof materials can be poured into the cavity 9 or waterproof adhesive strips are set.

[0036] The bottom of the upper box culvert 1 is horizontally provided with a transve...

Embodiment 3

[0038] see figure 1 , a new type of assembled box culvert, mainly composed of an upper box culvert 1 and a lower box culvert 2, the upper box culvert 1 is provided with a plurality of vertical steel bars 3, and the vertical steel bars 3 protrude in the vertical direction The upper box culvert 1 is outside; the lower box culvert 2 is provided with a plurality of steel sleeves 4 adapted to the vertical steel bars in the upper box culvert; the vertical steel bars 3 are screwed to the steel sleeves 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com