Seepage draining method for fine-grained tailing pond, seepage draining system and application

A technology for fine-grained tailings and tailings is applied in the field of seepage drainage systems and seepage-removal methods for fine-grained tailings ponds, which can solve the problem of difficulty in accelerating fine-grained tailings consolidation dam body wetting lines and tailings blocking. , limited seepage effect, etc., to achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

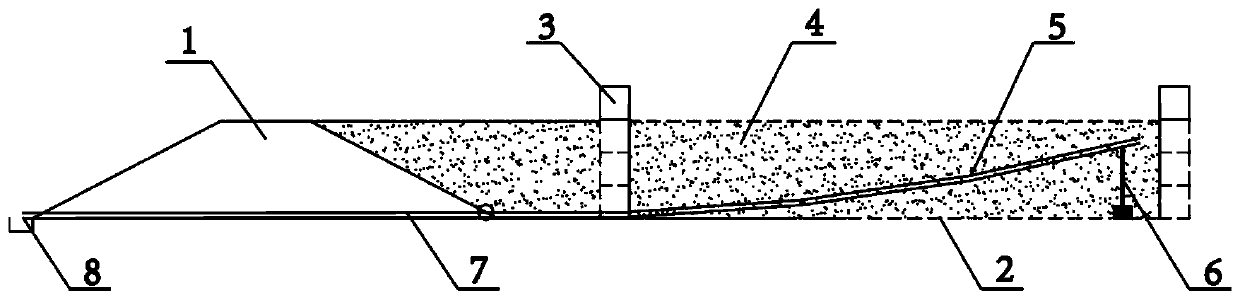

[0101] This embodiment provides a method for seepage drainage of a fine-grained tailings pond, comprising the following steps:

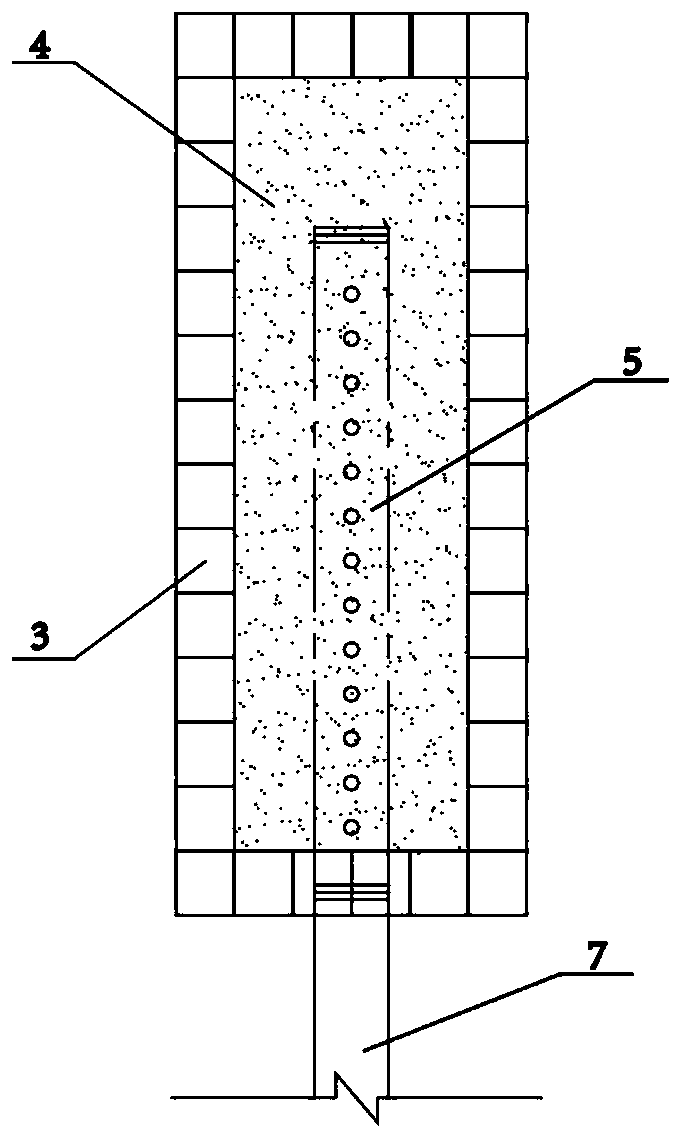

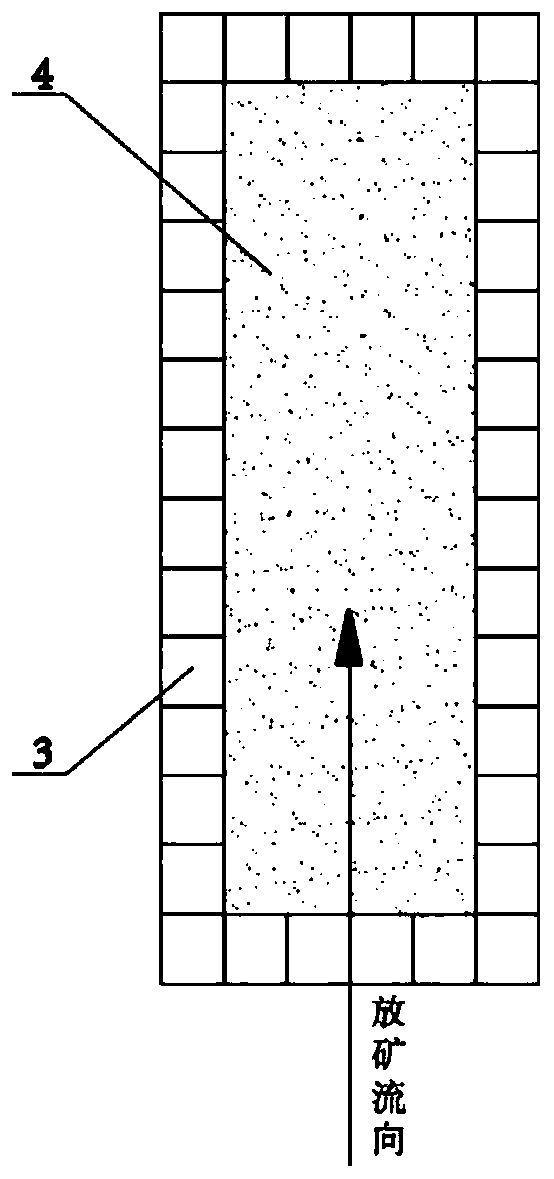

[0102] A hollow rectangular seepage drainage area with a length of 30m, a width of 1m and a height of 0.5m is set up on the beach surface in front of the sub-dam of the fine-grained tailings reservoir by multiple floating barrels, and the seepage area is perpendicular to the axis of the sub-dam Set in the direction (that is, the long side of the seepage area is perpendicular to the direction of the sub-dam axis, and the short side is parallel to the direction of the sub-dam axis), and the distance between the side of the seepage area near the sub-dam and the sub-dam is 10m;

[0103] The fine-grained tailings (-0.074mm particle content 77%, -0.020mm particle content 49%) are discharged into the fine-grained tailings reservoir and outside the seepage area, and the coarse-grained tailings (-0.074mm particle content content of 25%) through the ore-drawin...

Embodiment 2

[0107] This embodiment provides a seepage drainage method for a fine-grained tailings dam, except that the curvature of the seepage drainage pipe is 0.8° / m, and other steps are the same as those in Example 1.

Embodiment 3

[0109] This embodiment provides a seepage drainage method for a fine-grained tailings pond, except that the slope of the aqueduct is 1.5%, and other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com