Anti-shear spring shock absorber

A spring shock absorber and anti-shear technology, which is applied in the field of spring shock absorbers, can solve the problems of high cost, complicated installation, tearing off, etc., and achieve the effect of good shear resistance, large contact area, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

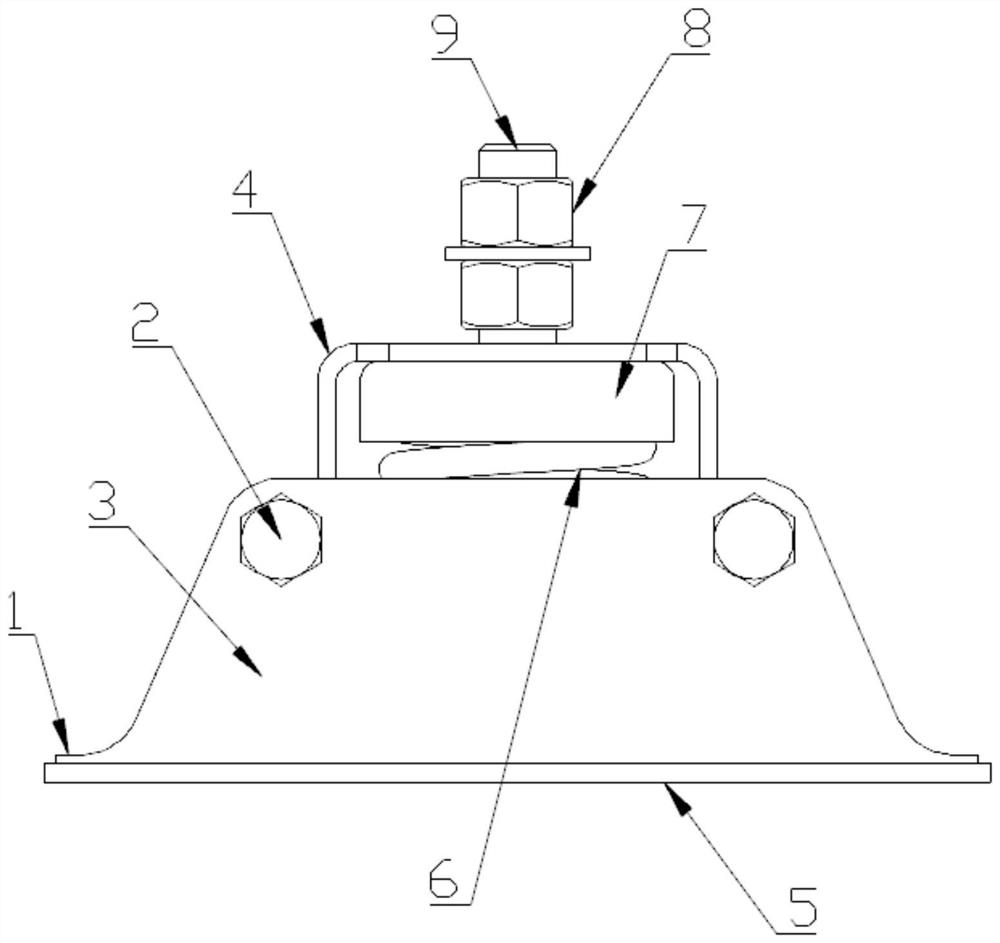

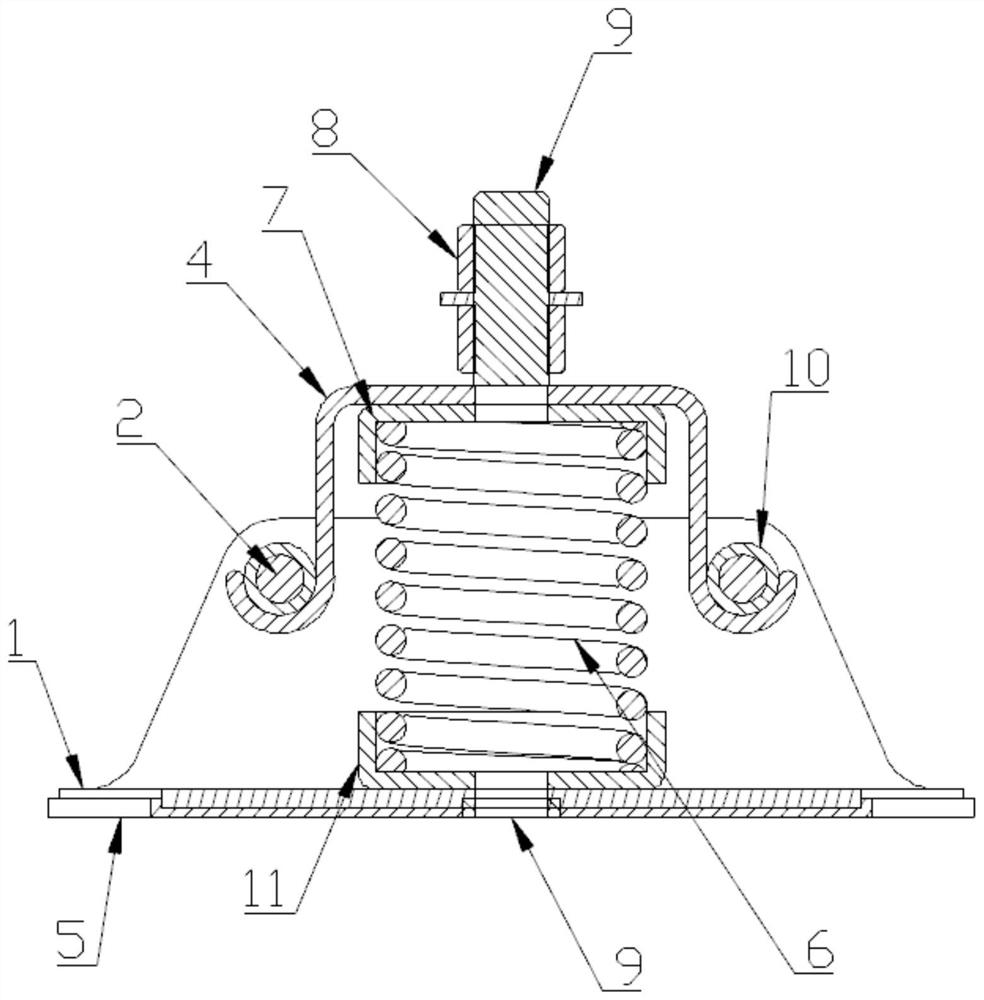

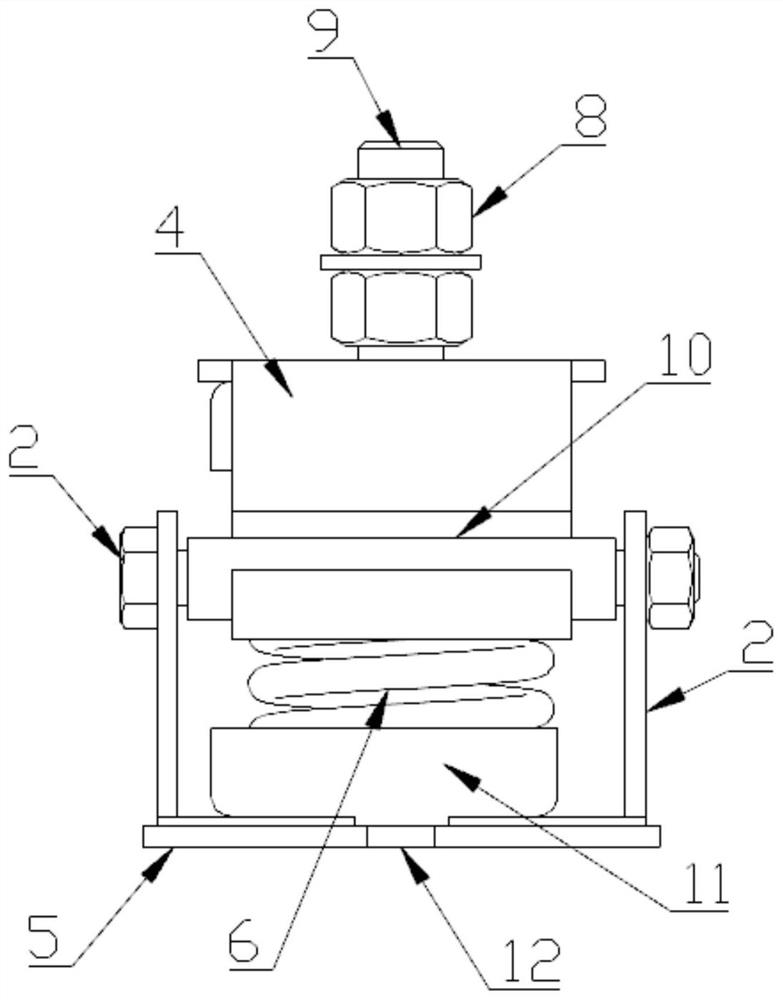

[0026] Such as figure 1 , 2 As shown, an anti-shear spring shock absorber includes a spring body 6 , an upper cover 7 , a lower cover 11 , a bottom plate 1 , a limiting plate 4 , a vertical plate 3 , and a positioning bolt 2 . Described spring body 6 contacts with upper cover 7, lower cover 11 of bowl dress respectively up and down, upper cover 7, lower cover 11 cavity diameters are slightly larger than spring body 6 maximum diameters, upper cover 7, lower cover 11 and spring body 6 The gap between them is small.

[0027] The lower surface of the lower cover 11 is fixed to the center of the base plate 1 by bolts, and the left and right sides of the base plate 1 are provided with mounting gaps 12, the base plate 1 can be locked on the mounting surface through the mounting gaps 12, and the mounting gaps 12 can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com