Design method of three-dimensional inward turning air inlet channel capable of simultaneously controlling shock wave and pressure distribution

A pressure distribution and air inlet technology, applied in computing, image data processing, special data processing applications, etc., can solve the problem that the incident shock wave and the isentropic compression process cannot be controlled at the same time, and achieve the effect of widening the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

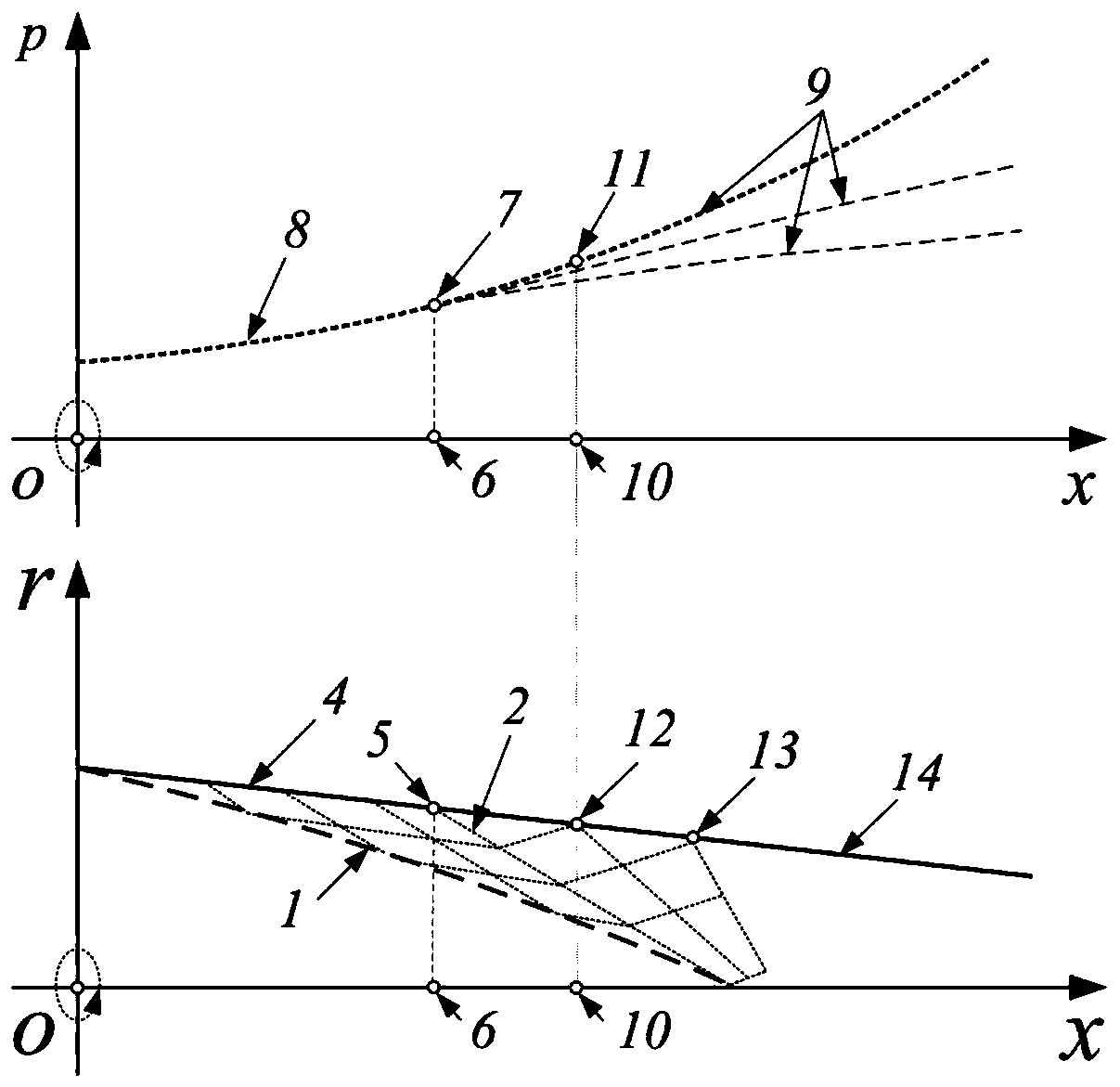

[0029] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

[0030] The main implementation steps of the three-dimensional inward turning inlet design method with simultaneous controllable shock wave and pressure distribution include:

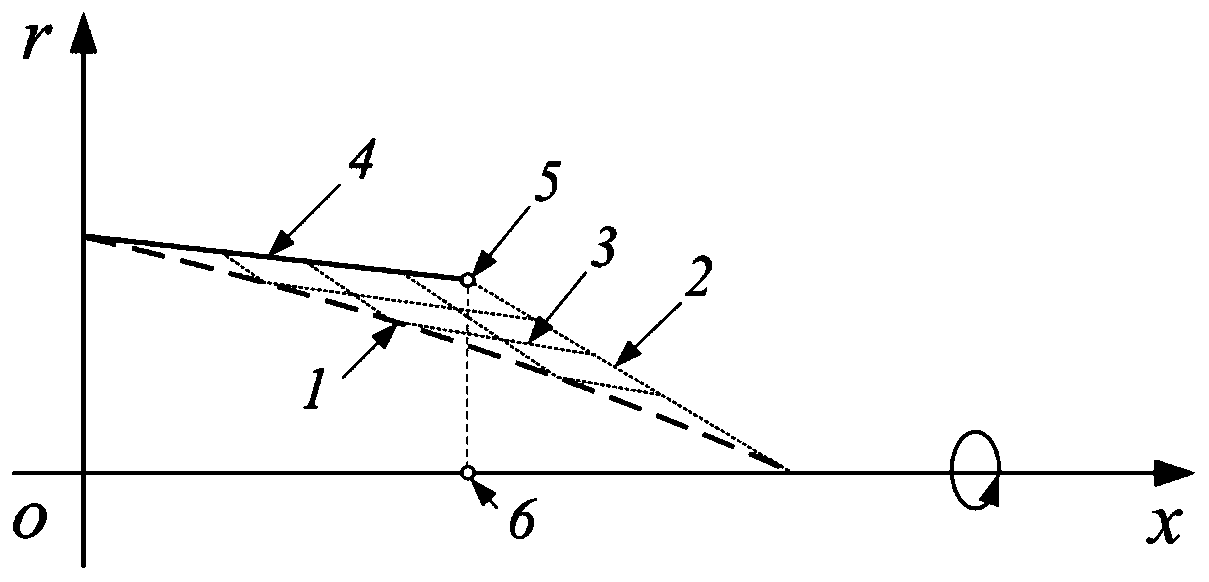

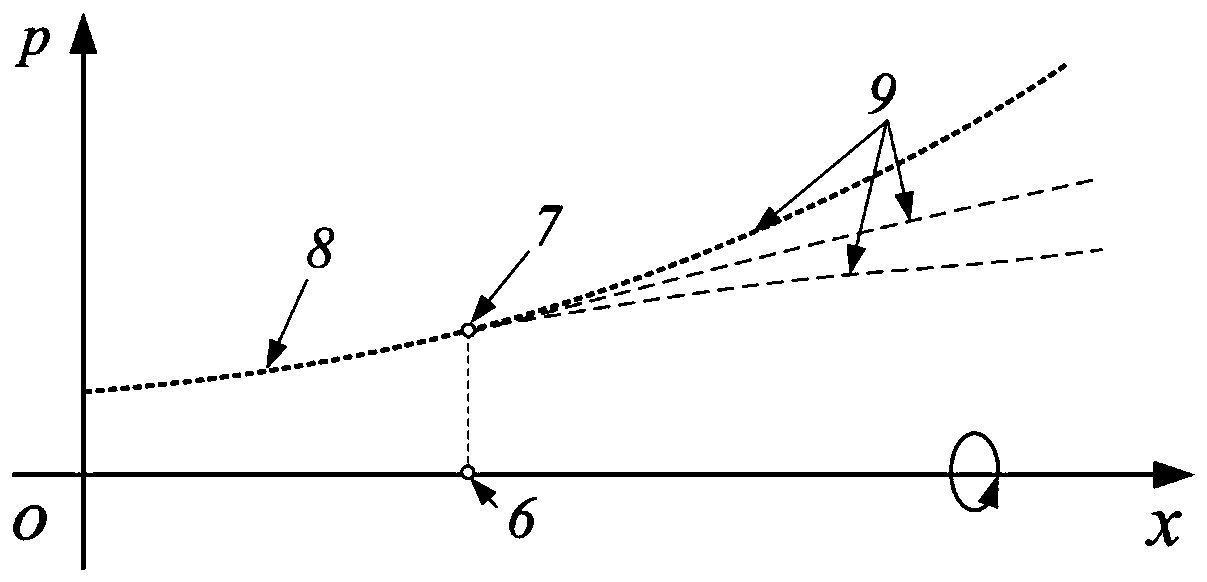

[0031] (1) Design the incoming flow conditions and the incident shock wave curve 1, and inversely calculate the wall profile according to the characteristic line method. The incoming flow condition is the design condition of the aircraft, and the incident shock wave curve 1 can be designed as a curved incident shock wave. Using the characteristic line method, the incoming flow condition and the incident shock wave curve 1 are used as input conditions to solve the right-hand characteristic line 2 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com