Double-sided water-cooled sic half-bridge module packaging structure with integrated laminated busbar

A stacked busbar and module packaging technology, which is applied to semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problem of poor heat dissipation efficiency, the method of reducing power terminals, and the balanced heat dissipation of SiC semiconductor chips, etc. problem, to reduce the area of the commutation circuit, solve the problem of large inductance, and reduce the effect of parasitic inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described below in conjunction with the accompanying drawings.

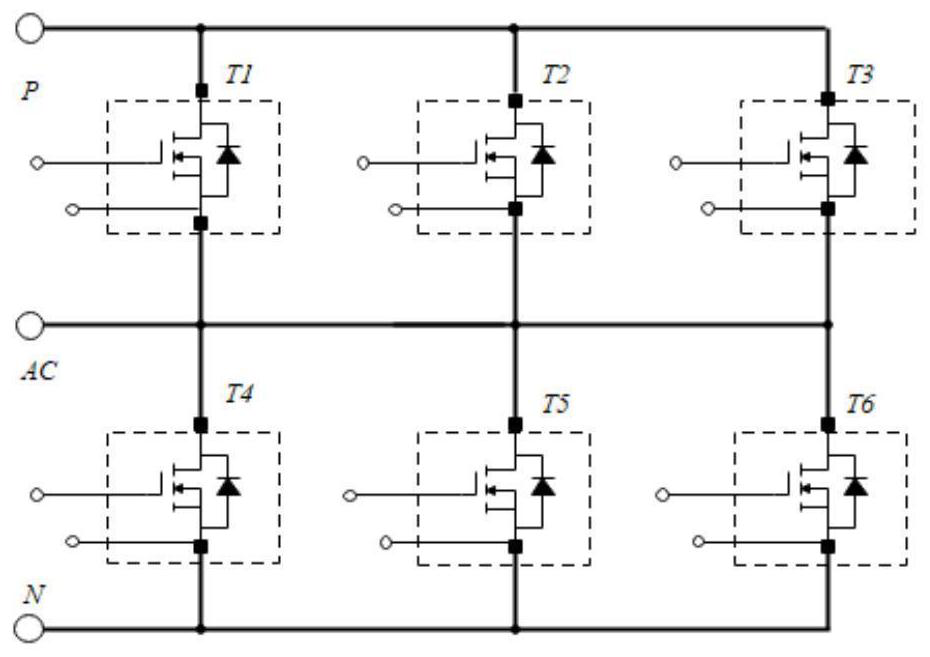

[0051] figure 1 It is a circuit diagram of the packaging structure of the present invention. In the figure, P is the DC positive pole, N is the DC negative pole, AC is the AC terminal, T1-T6 are six SiC semiconductor chips 5, wherein T1, T2 and T3 are SiC semiconductor chips 5 connected in parallel on the upper bridge arms, T4, T5 and T6 is the SiC semiconductor chip 5 connected in parallel to the lower bridge arm, and the parallel connected SiC semiconductor chip 5 increases the total current, so that the package structure can integrate more power.

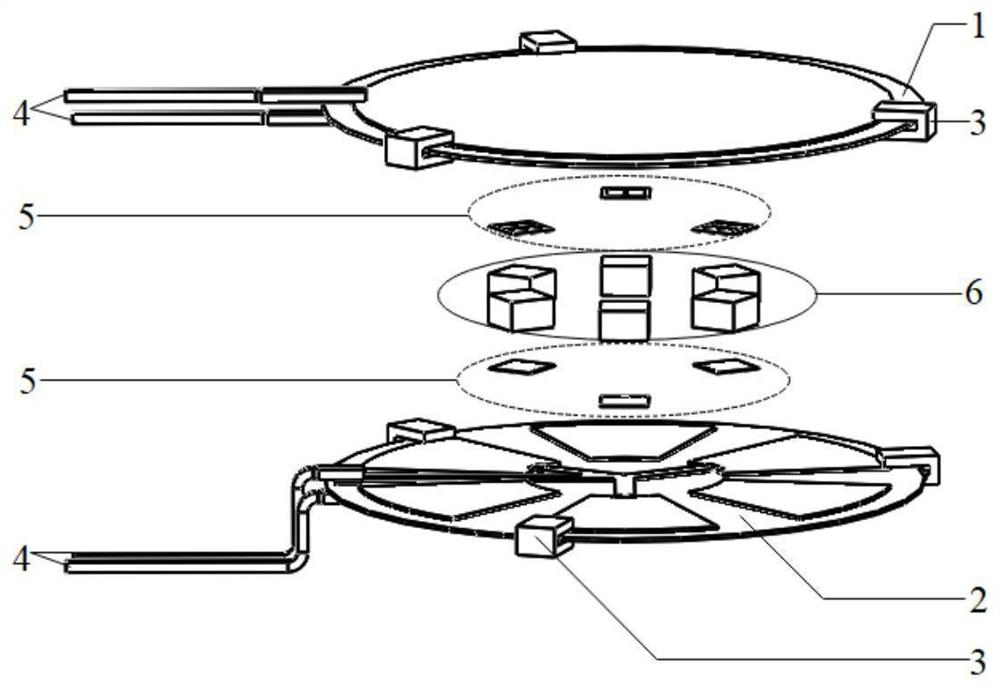

[0052] The packaging structure of the double-sided water-cooled SiC half-bridge module integrating laminated busbars of the present invention includes a main structure, an external connection structure and a heat dissipation device. The main structure includes an upper DBC1, a lower DBC2, six SiC semiconductor chips 5 and six A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com