Protection assembly structure and method of switched reluctance motor for bullet train

A switched reluctance motor and assembly structure technology, which is applied to electromechanical devices, electric components, electrical components, etc., can solve the problem of less protection structure schemes for reluctance motors, and achieves easy and efficient installation in place, improves installation stability, reduces The effect of small vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

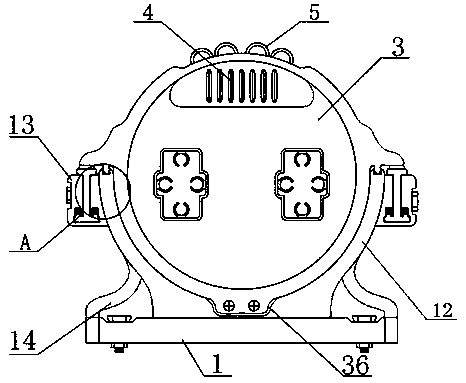

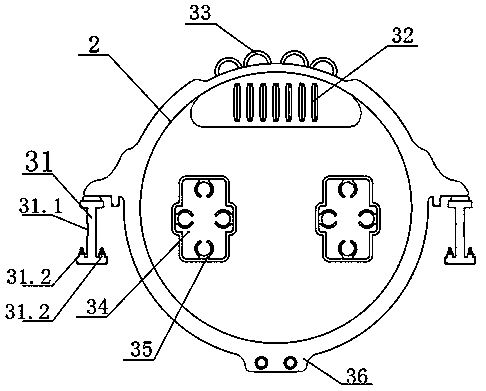

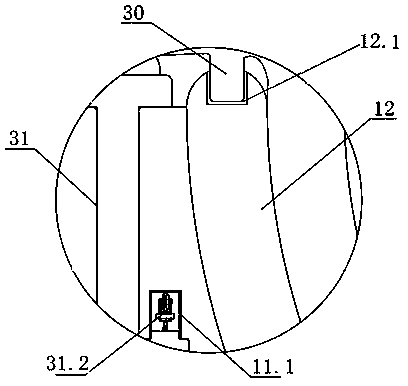

[0030] Combine below Figure 1 to Figure 7 Embodiments of the present invention are described in detail.

[0031] The protective assembly structure of the switched reluctance motor for motor vehicles, including the base 1 on which the motor body is fixed, the top cover shell 2 covering the top of the motor body, and the rear cover shell covering the back of the motor body and integrally formed with the top cover shell 2 3. It is characterized in that the rear cover shell 3 has a snap-in rod 31 arranged horizontally, the base 1 has a slot 11 corresponding to the snap-in rod 31, and the rear cover shell 3 is guided and matched with the snap-in rod 31 Inserted into the slot 11 and covered on the back of the motor body, the snap-in rod 31 is clipped and positioned in the slot 11 to position the rear cover shell 3 and the top cover shell 2 on the base 1 .

[0032] In the protective assembly structure of the switched reluctance motor for motor vehicles described above, the base 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com