Pressing apparatus for egg tart skin forming

A technology of extrusion equipment and egg tart skin, which is applied in the direction of dough extrusion machine, etc., can solve the problems of easily hurting hands and difficult to collect, and achieves the effect of high safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

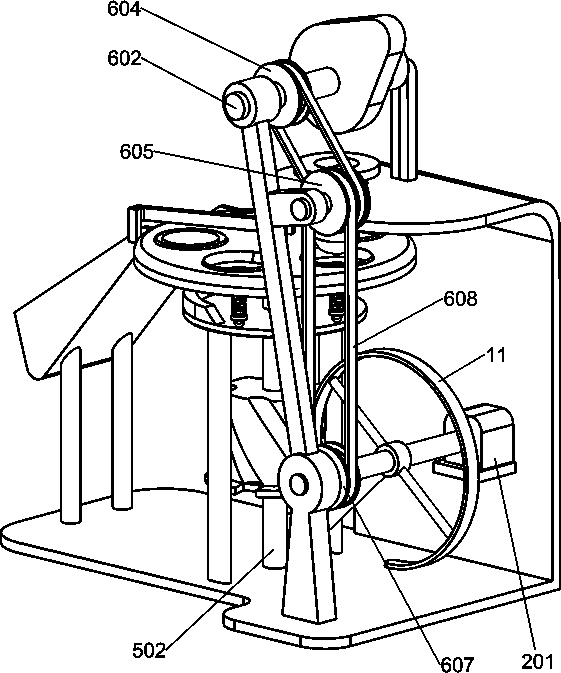

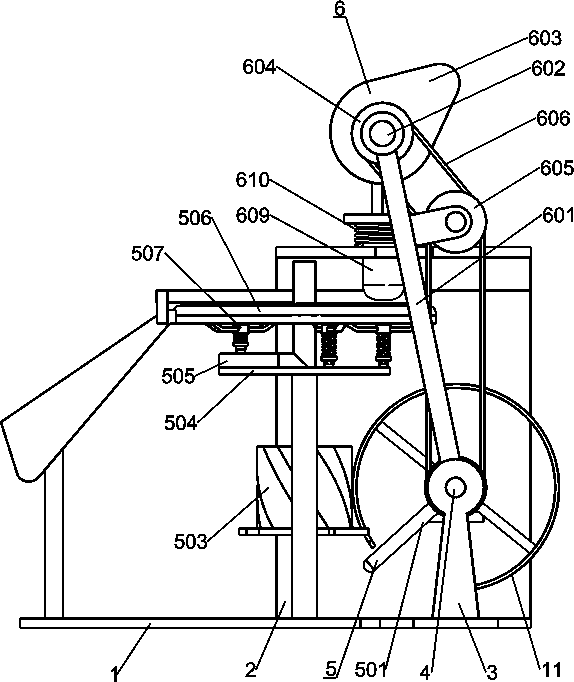

[0021] An extrusion equipment for forming egg tart wrappers, such as Figure 1-4 As shown, it includes a bottom plate 1, a frame 2, a servo motor 201, a support base 3, a first rotating shaft 4, a rotating assembly 5, and an extrusion assembly 6. The top rear side of the bottom plate 1 is fixedly connected with a frame 2, and the front of the frame 2 A servo motor 201 is installed on the right side of the side, a support base 3 is installed on the top right front side of the bottom plate 1, and a first rotating shaft 4 is arranged on the upper part of the supporting base 3 to rotate. The rear end of the first rotating shaft 4 is connected with the output shaft of the servo motor 201, and the bottom plate 1 There is a rotating assembly 5 connected to the first rotating shaft 4. The top of the frame 2 is provided with an extruding assembly 6 which is connected to the first rotating shaft 4.

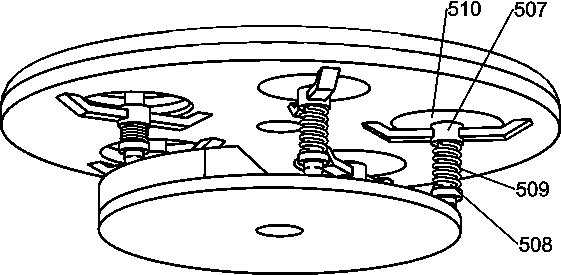

[0022] The rotating assembly 5 includes a drive rod 501, a second rotating shaft 502, a hol...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 1-3 As shown, a blocking rod 7 and a collecting bucket 8 are further included. A collecting bucket 8 is provided on the left side of the top of the bottom plate 1, and a blocking rod 7 is provided on the front side of the top of the collecting bucket 8, and the blocking rod 7 is located on the upper surface of the tray 506.

[0029] It also includes a limit disk 9 and a limit frame 11. The lower part of the second rotating shaft 502 is provided with a limit disk 9, and the upper part of the limit disk 9 is connected to the bottom of the hollow tank 503. The limit grooves 10 are evenly spaced on the outside of the limit disk 9. A limit frame 11 is provided in the middle of a rotating shaft 4.

[0030] When the squeezed egg tart wrapper pushed up by the push block 510 touches the stop lever 7, since the loading tray 506 will continue to rotate, the egg tart wrapper will automatically fall into the collection bucket 8, making it more c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com