Protective nose plug and manufacturing method thereof

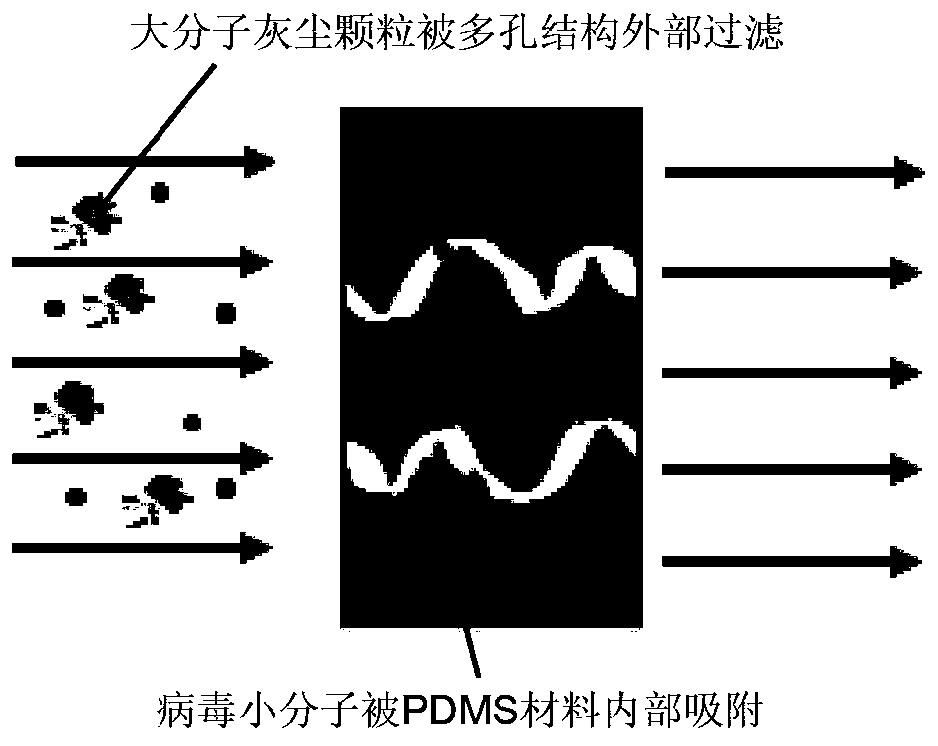

A technology for nasal congestion and sucrose, which is applied in the field of medical and sanitary products, can solve the problems of complicated preparation devices and processes, masks cannot actively absorb viruses and dust particles, etc., and achieves the effects of good protection effect, small size and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

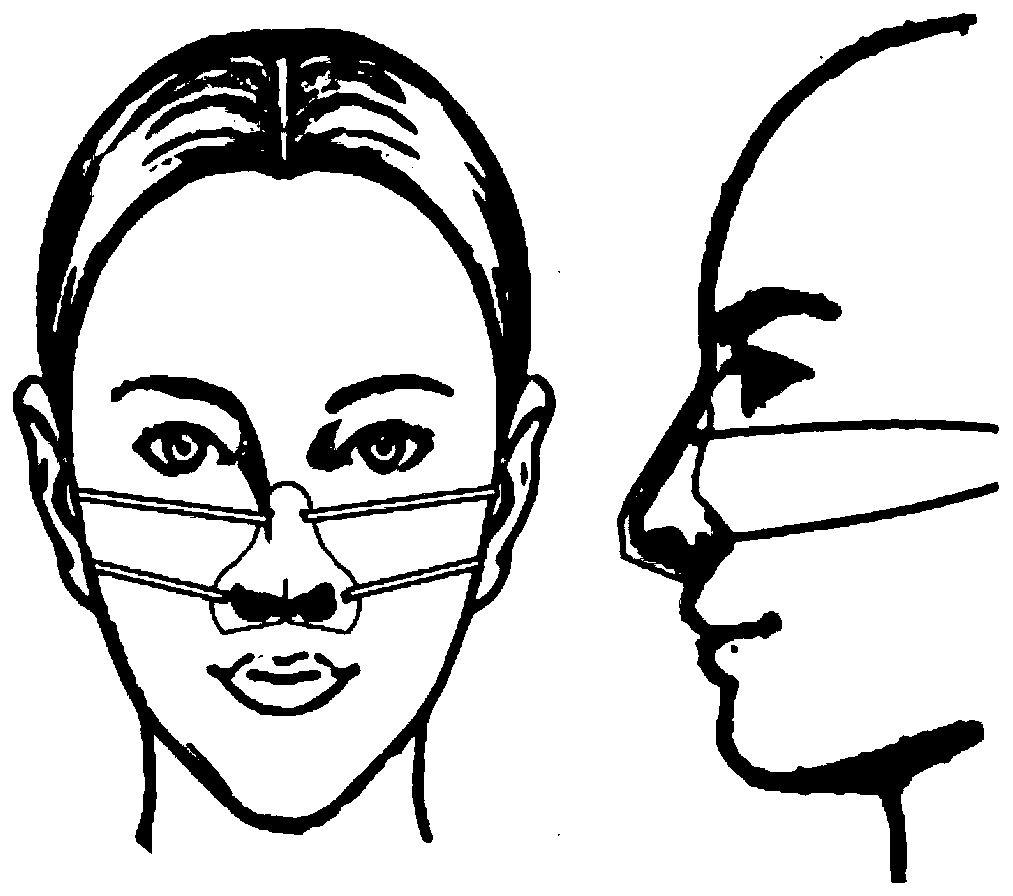

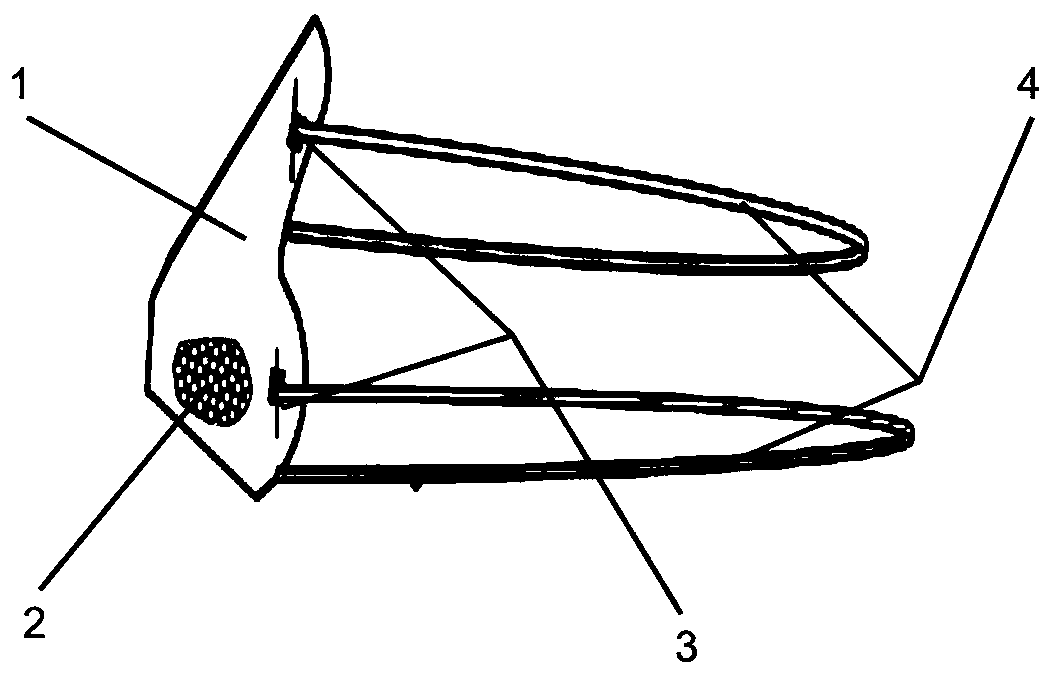

[0024] Specific embodiment 1: This embodiment describes a protective nasal plug, which is made of porous PDMS material, such as Figure 6 shown.

specific Embodiment approach 2

[0025] Specific embodiment two: a preparation method for protecting nasal congestion described in specific embodiment one, such as Figure 4 As shown, the method steps are as follows:

[0026] Step 1: Pour sucrose evenly into the nasal plug mold to reach the height of the sucrose, and then compact and smooth it; specifically, the structure of the nasal plug mold can be designed with reference to the earplug mold, and there is no need to make a unified limit, as long as the shape of the prepared nasal plug can be ensured It is enough to plug the nostrils; the height of the sucrose height line does not need to be uniformly limited, and can be adjusted appropriately according to the length of the nasal congestion into the nostrils;

[0027] Step 2: Pour the prepared PDMS into the mold. The highest liquid level of PDMS cannot be higher than the lowest point of sucrose; in this step, the highest liquid level of PDMS cannot be higher than the lowest point of sucrose. After flowing ...

specific Embodiment approach 3

[0030] Specific embodiment three: a preparation method for protecting nasal congestion described in specific embodiment two, in step two, the prepared PDMS is obtained by pouring PDMS glue and curing agent into a container according to a mass ratio of 10:1 and stirring well of.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap