Large-particle compound fertilizer granulating and forming device

A molding device and compound fertilizer technology, which are used in the extrusion granulation of raw materials, granulation in static tanks/slots, and mixers, etc., can solve problems such as uneven material shape, clogging of radial holes in equalizers, clogging, etc. , to achieve the effect of reducing maintenance and cleaning time and improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings, a pressurized disc filter of the present invention is further described, and the present invention is further described in detail below in conjunction with the embodiments:

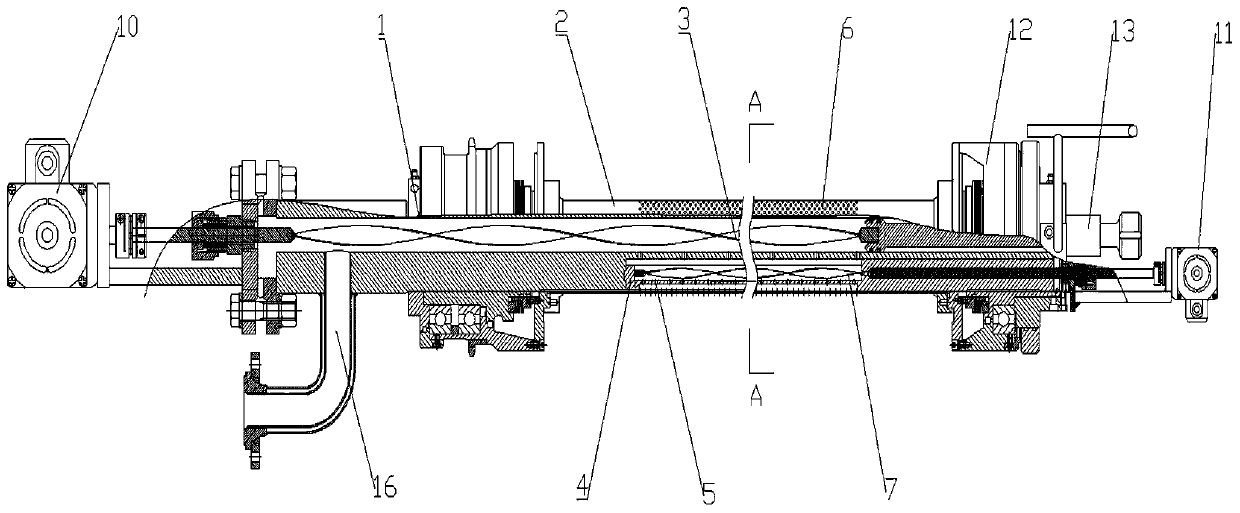

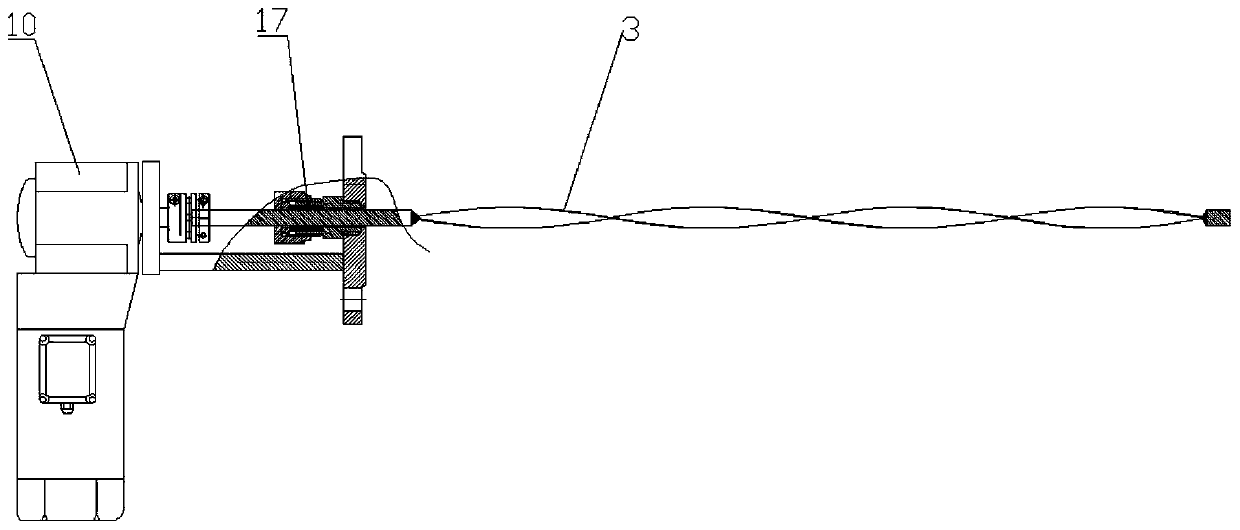

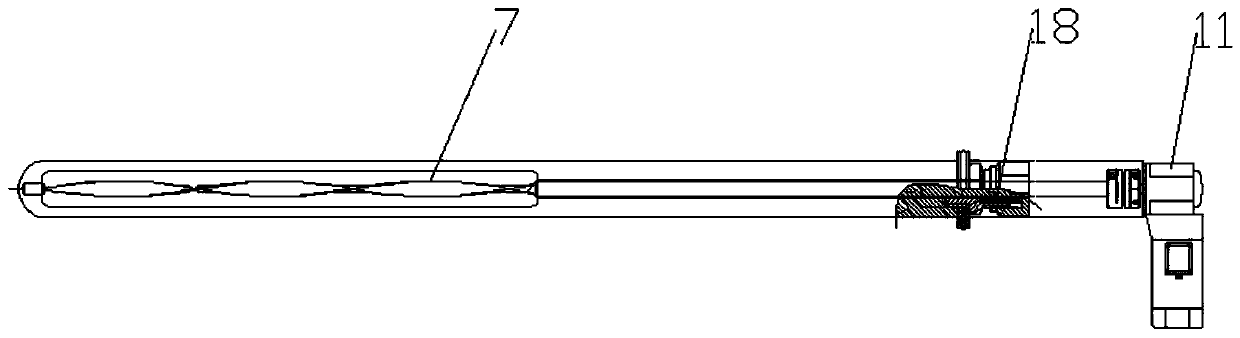

[0024] A large particle compound fertilizer granulation molding device, comprising a feed cylinder 1, a plurality of discharge holes 6 are opened on the surface of the feed cylinder 1, a stator 2 is installed inside the feed cylinder 1, and a stator 2 is formed inside the stator 2 The material channel, the first stirring screw 3 is horizontally and rotatably arranged in the material channel, the first stirring screw 3 can prevent the suspended matter in the molten material from easily sedimenting and accumulating at the bottom of the material channel, after a period of production, the material The radial channel will be blocked, which solves the problems of insufficient production, uneven material distribution, and uneven material shape. It must be shut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com