Leaf crusher and leaf processing technology

A technology of pulverizers and leaves, applied in grain processing, presses, manufacturing tools, etc., can solve the problems of energy waste, increase and decrease in the number of transportation, etc., and achieve the effects of improving transportation efficiency, fast drying, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

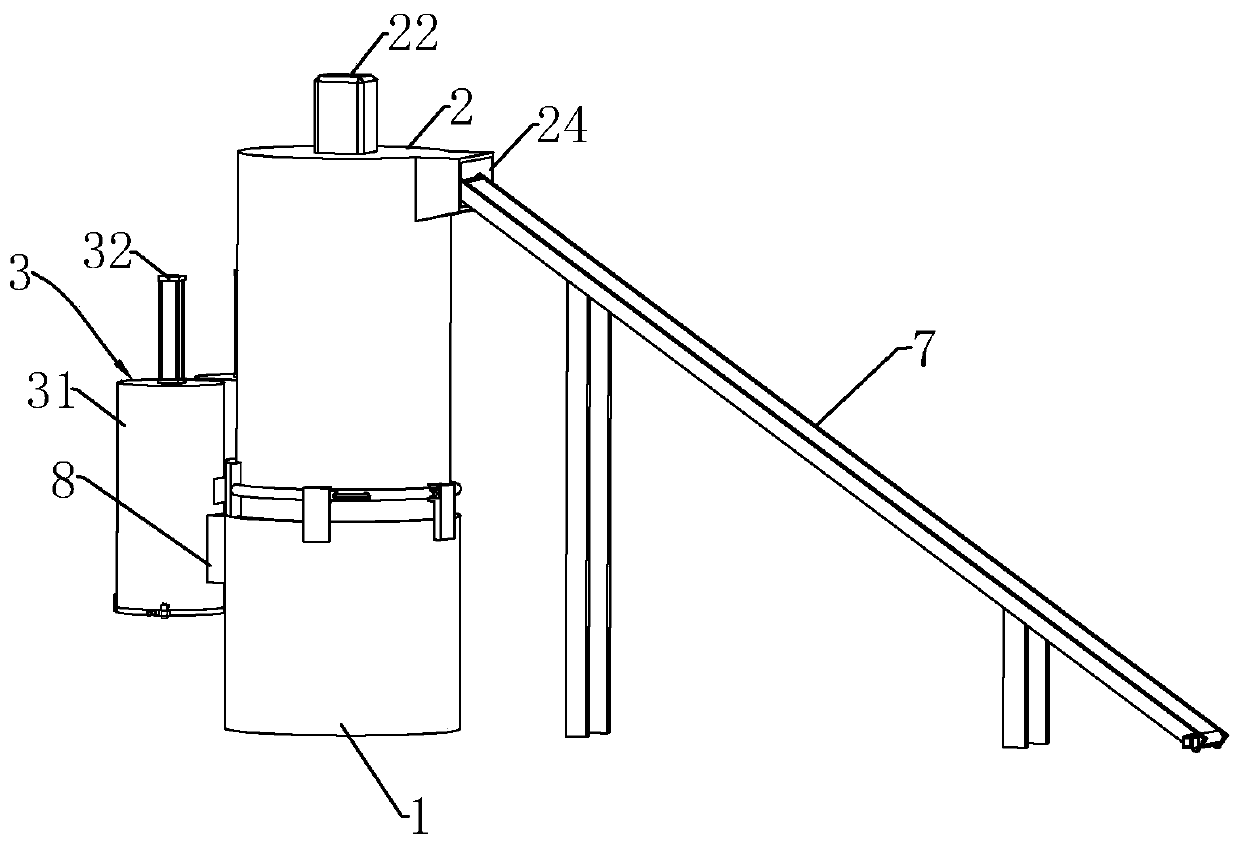

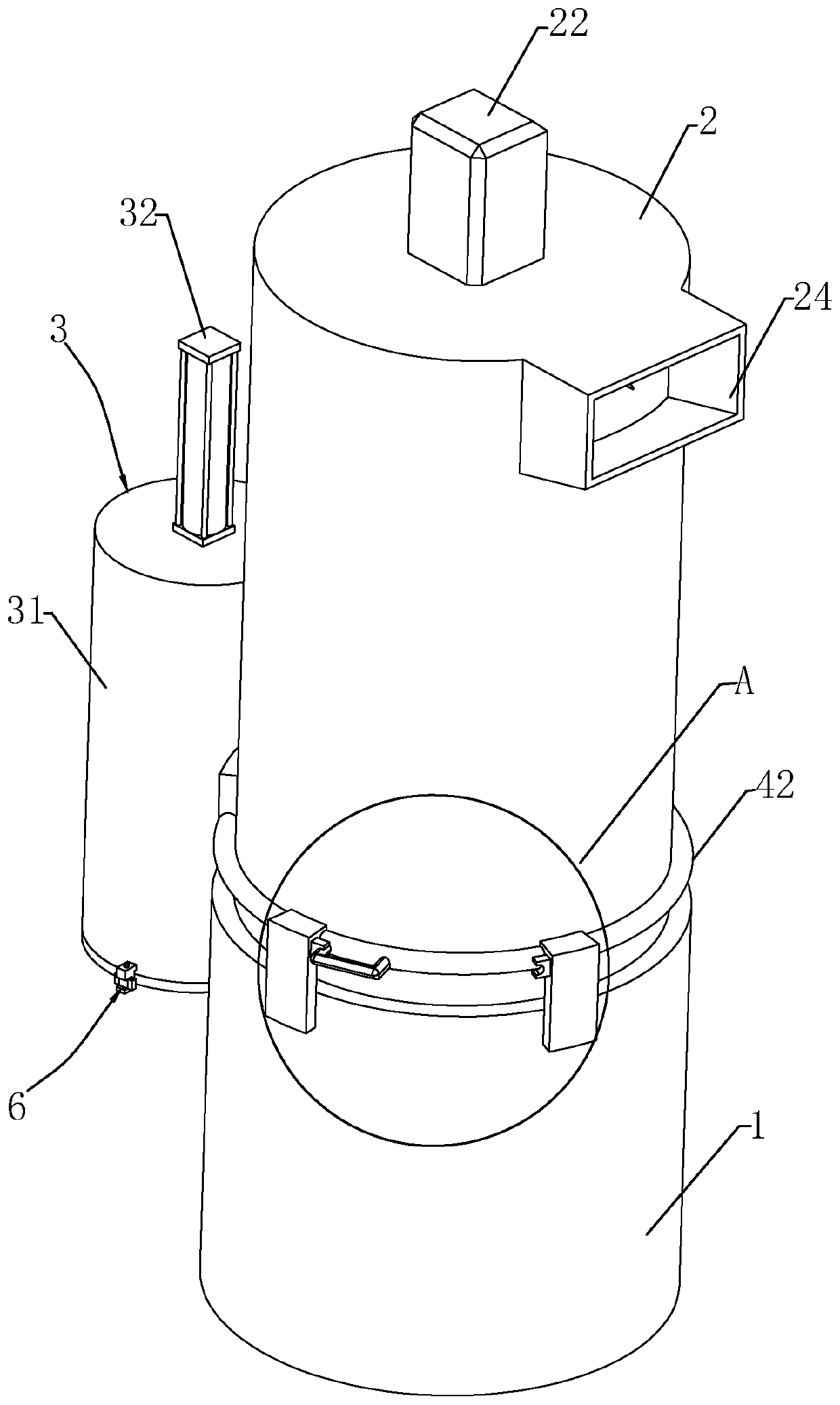

[0050] refer to figure 1 , is a leaf shredder disclosed by the present invention, comprising a base 1 with a circular cross-section and vertically arranged on the ground. axis settings.

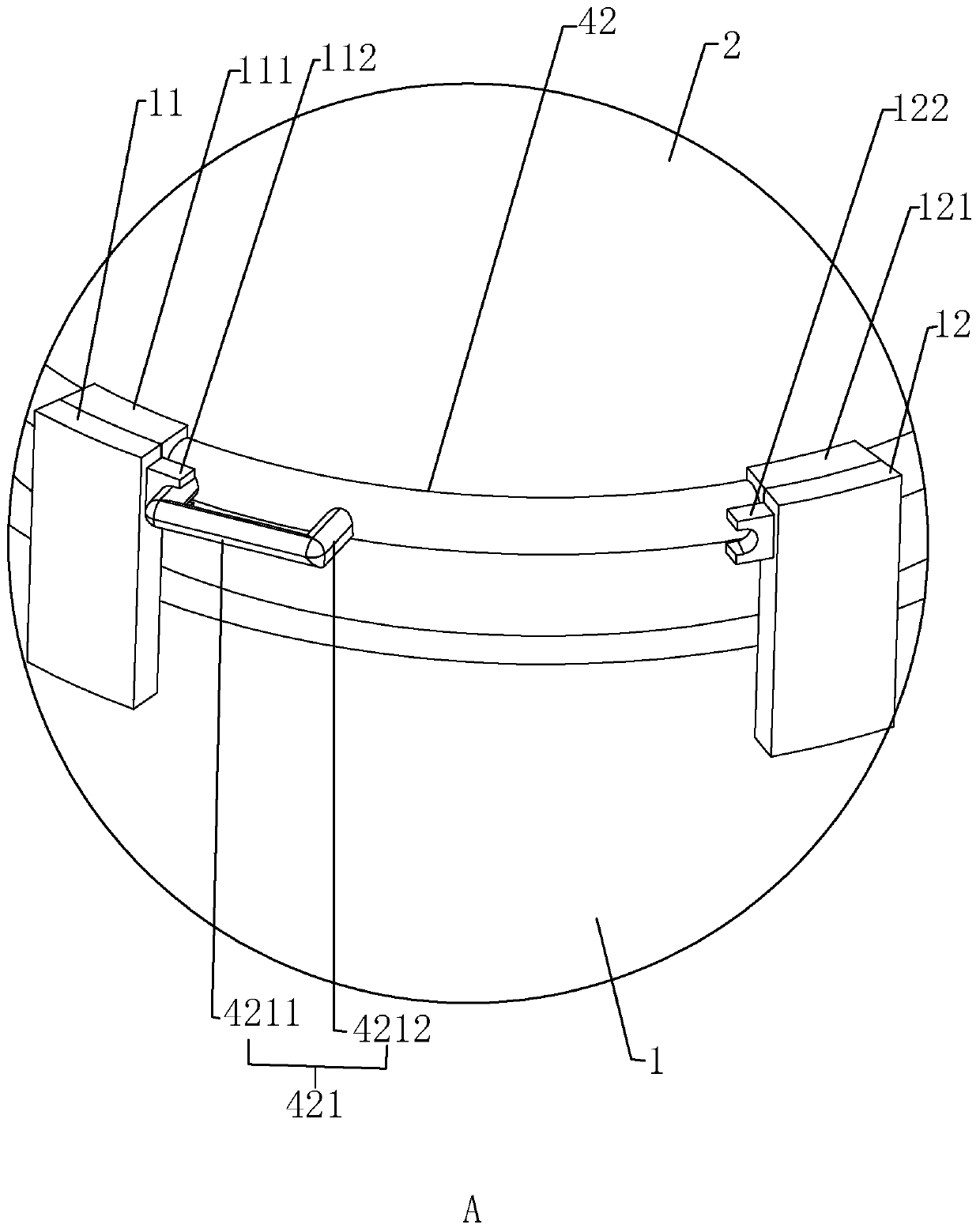

[0051] refer to figure 2 , Figure 4 , the crushing barrel 2 is provided with a cylindrical housing chamber 21, and a circular screen 9 is fixedly connected in the housing chamber 21, and the screen cloth 9 separates the housing chamber 21 into a crushing chamber 211 and a receiving chamber 212, and the crushing chamber 211 is located at Just above the receiving room 212. The upper surface of the crushing barrel 2 is fixedly connected with a driving motor 22, and the output shaft of the driving motor 22 penetrates downward into the crushing chamber 211, and the output shaft of the driving motor 22 is fixedly connected with a rotating rod 23, and the rotating rod 23 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com