Waste iron nail recovery equipment for building construction

A technology for building construction and recycling equipment, applied in construction, road cleaning, cleaning methods, etc., can solve problems such as equipment impact, economic waste, damage, etc., and achieve the effects of reliable work, reduced failure points, and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

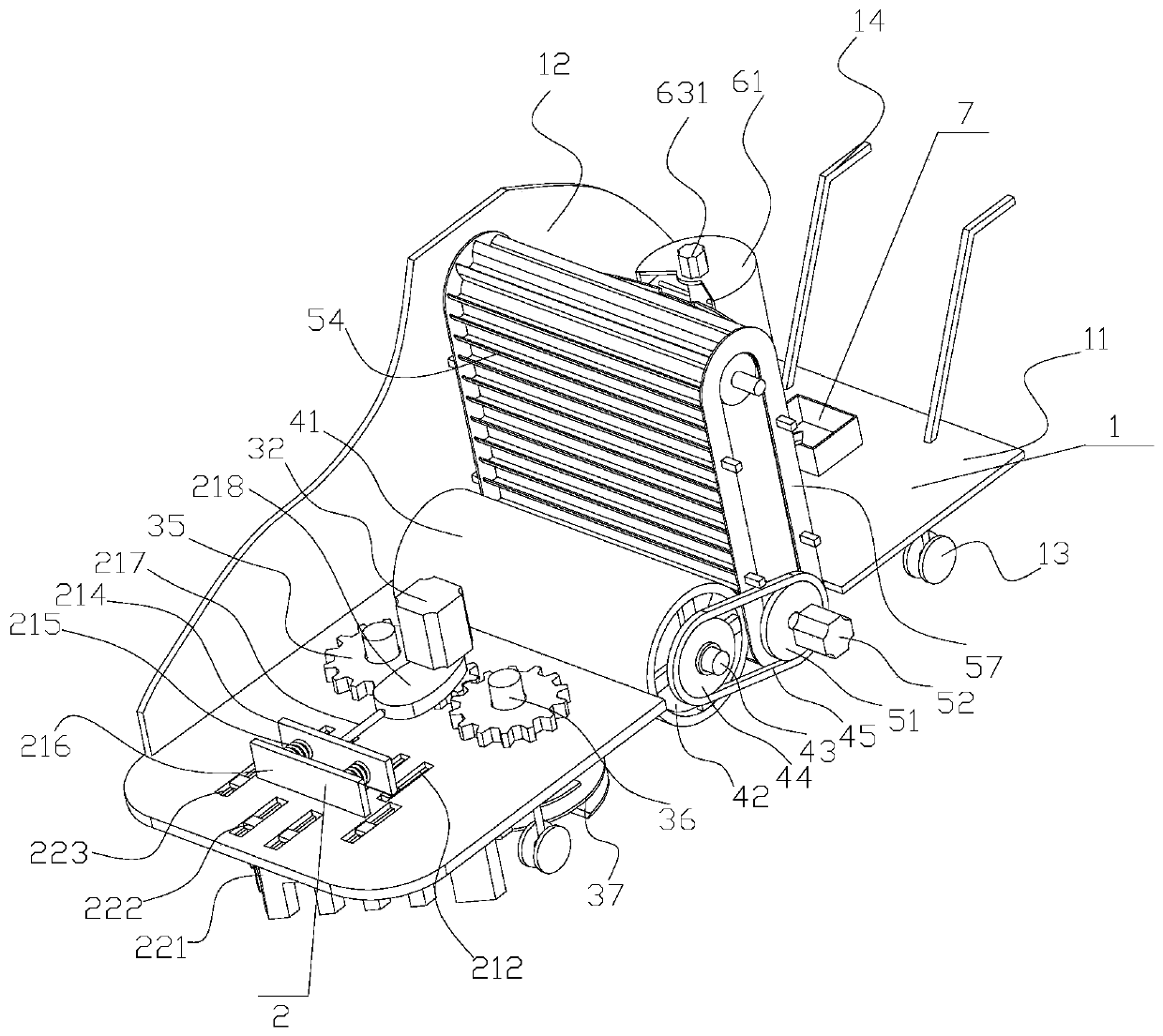

[0024] In order to enable those in the technical field to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

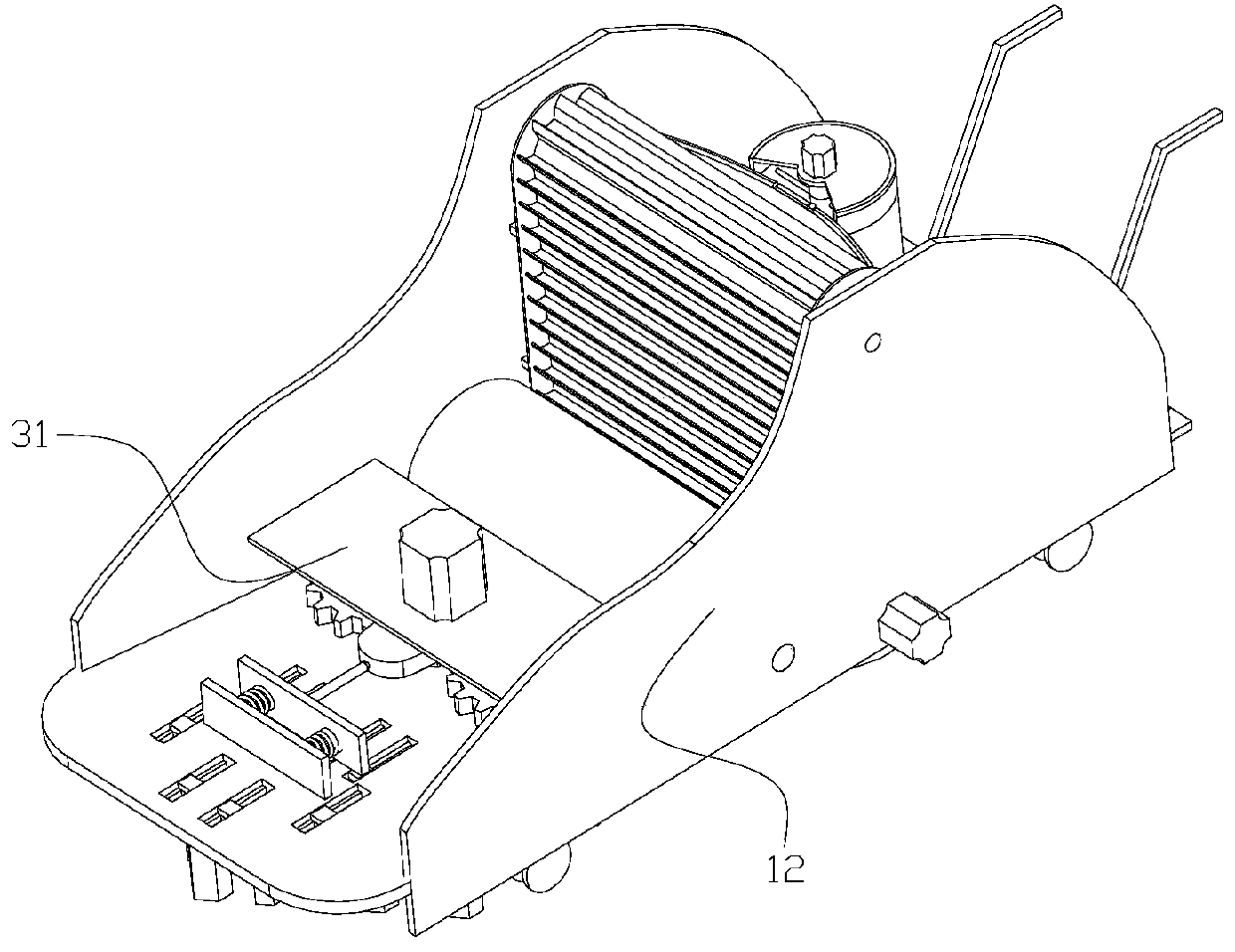

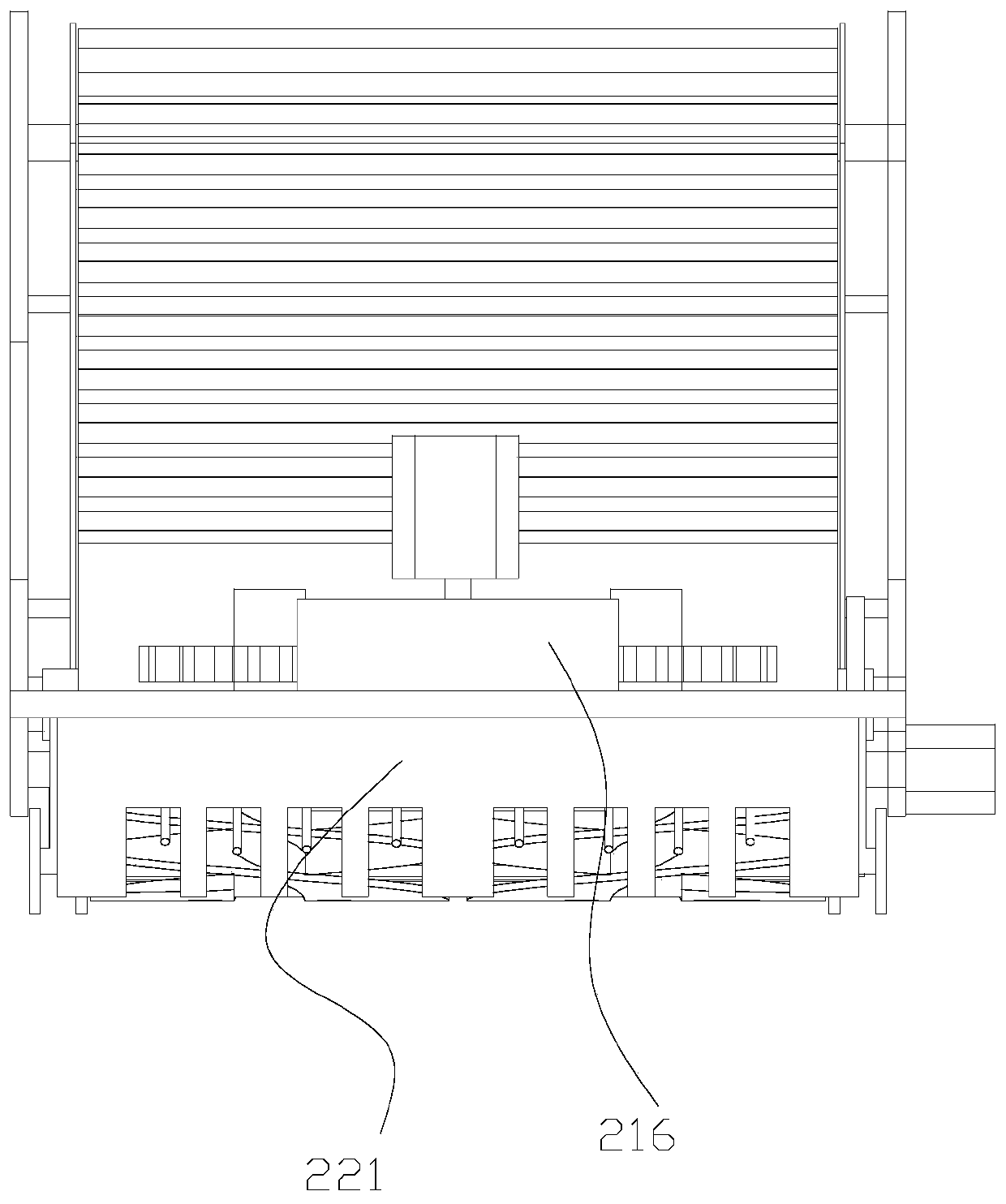

[0025] Such as figure 1 - As shown in 10, a waste iron nail recovery equipment for building construction, including frame 1, frame side plate 12, frame bottom plate 11, wheels 13, waste residue outlet 15, push handle 14, primary cleaning device 2, stone turning device 3. Adsorption device 4, material lifting device 5, screening device 6, collection box 7; the frame side plates 12 are symmetrically arranged on both sides of the frame 1; wheels 13 are arranged below the frame bottom plate 11; The waste residue outlet 15 is provided on the frame bottom plate 11; the push handle 14 is located at the rear of the frame 1; the primary cleaning device 2 is located below the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com