Balanced type air-driven hydraulic pump

A pneumatic-hydraulic pump, balanced technology, applied in the field of hydraulic pumps, can solve the problems of easy frosting and freezing of compressed gas, small flow rate, difficult pump aerodynamics, etc., and achieve the effect of quick ventilation, high working efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

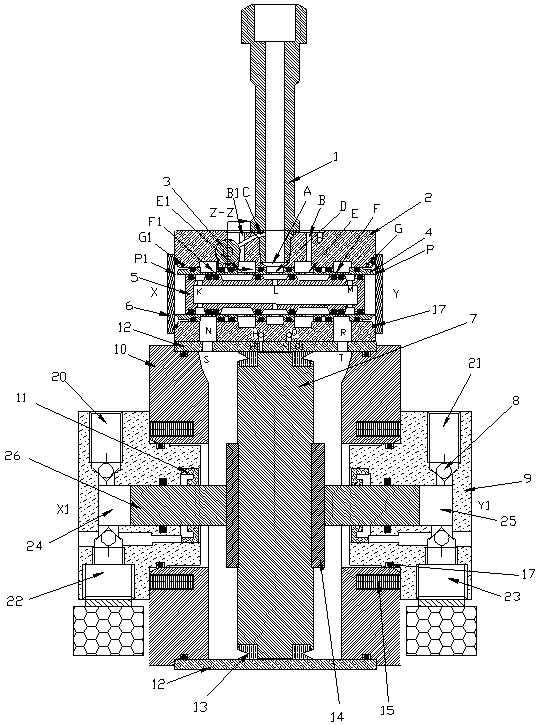

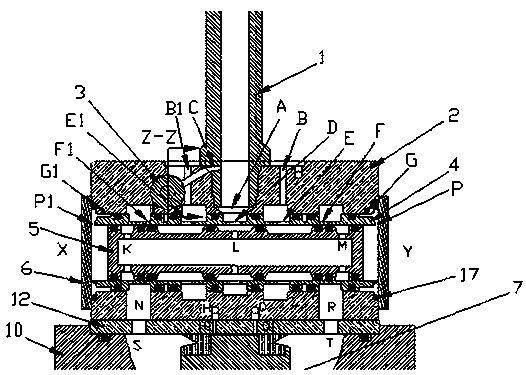

[0022] Embodiment 1: as Figure 1-9 Shown: a balanced pneumatic hydraulic pump, characterized in that it includes a plunger body 9, an end cover body 10, a piston barrel 12, a piston 7 arranged in the piston barrel, a piston linkage shaft 26, and a top set of the piston barrel 12. There is a reversing valve body 2 reversing control mechanism, and the reversing valve control mechanism includes: a compressed gas inlet pipe 1 connected to the reversing valve body, a long slide shaft 5 arranged in the chamber of the reversing valve body 2, and a The copper sleeve 4 in the chamber of the long sliding shaft 5 and the reversing valve body 2, the short sliding shaft 3 in the reversing valve body 2, and the plugs 18 at both ends of the short sliding shaft 3 are arranged in the reversing valve body 2 the external baffle plate 6, the lower left side of the reversing valve body 2 is provided with an inner vent hole N, and the inner vent hole N is connected with the piston barrel vent hole...

Embodiment 2

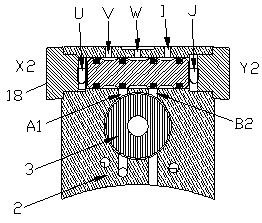

[0028] Embodiment 2: as Figure 4-6 Shown: a working method of a balanced pneumatic hydraulic pump: compressed gas passes through the C hole of the intake pipe 1 → enters the third built-in air intake W of the reversing valve body 2 → at this time, if the short slide shaft 3 is stressed to Y2 Direction movement, when moving to the seventh built-in air port B2 of the reversing valve body → enter the left air port G1 of the reversing valve body → enter the P1 port on the left end of the copper sleeve 4, at this time the compressed gas pushes the long sliding shaft in the copper sleeve 4 The end of 5 moves in the Y direction. When the long sliding shaft 5 moves to the air port F1 of the copper sleeve in the copper sleeve 4, the compressed gas passes through the intake pipe 1 → enters the air inlet A of the reversing valve body → enters the copper sleeve in the reversing valve body Air inlet D → enter the air inlet L in the middle of the long sliding shaft 5 → due to the limitatio...

Embodiment 3

[0030] Embodiment 3: as Figure 7-9 Shown: Another working method of balanced air-hydraulic pump: Compressed gas passes through the C hole of the intake pipe 1 → enters the built-in third air intake W of the reversing valve body 2 → at this time, if the short slide shaft 3 is forced toward Move in the X2 direction, when moving to the air port A1 → enter the lower air port G on the right side of the reversing valve body 2 → pass through the P port on the right end of the copper sleeve 4, at this time the compressed gas pushes the long sliding shaft 5 in the copper sleeve 4 to the end face Moving in the X direction, when the long sliding shaft 5 moves to the air port F of the copper sleeve 4 in the copper sleeve 4, the compressed gas passes through the intake pipe 1 → enters the air inlet A of the reversing valve body → enters the copper sleeve in the reversing valve body 4 Air inlet D → enter the air inlet L in the middle of the long sliding shaft 5 → due to the limitation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com