Integrated soybean milk boiler

A technology for cooking pulp and pot body, which is used in indirect heat exchangers, milk substitutes, steam boilers, etc., can solve the problems of agglomeration, unstable product quality, and large capacity of pulp cooking pots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

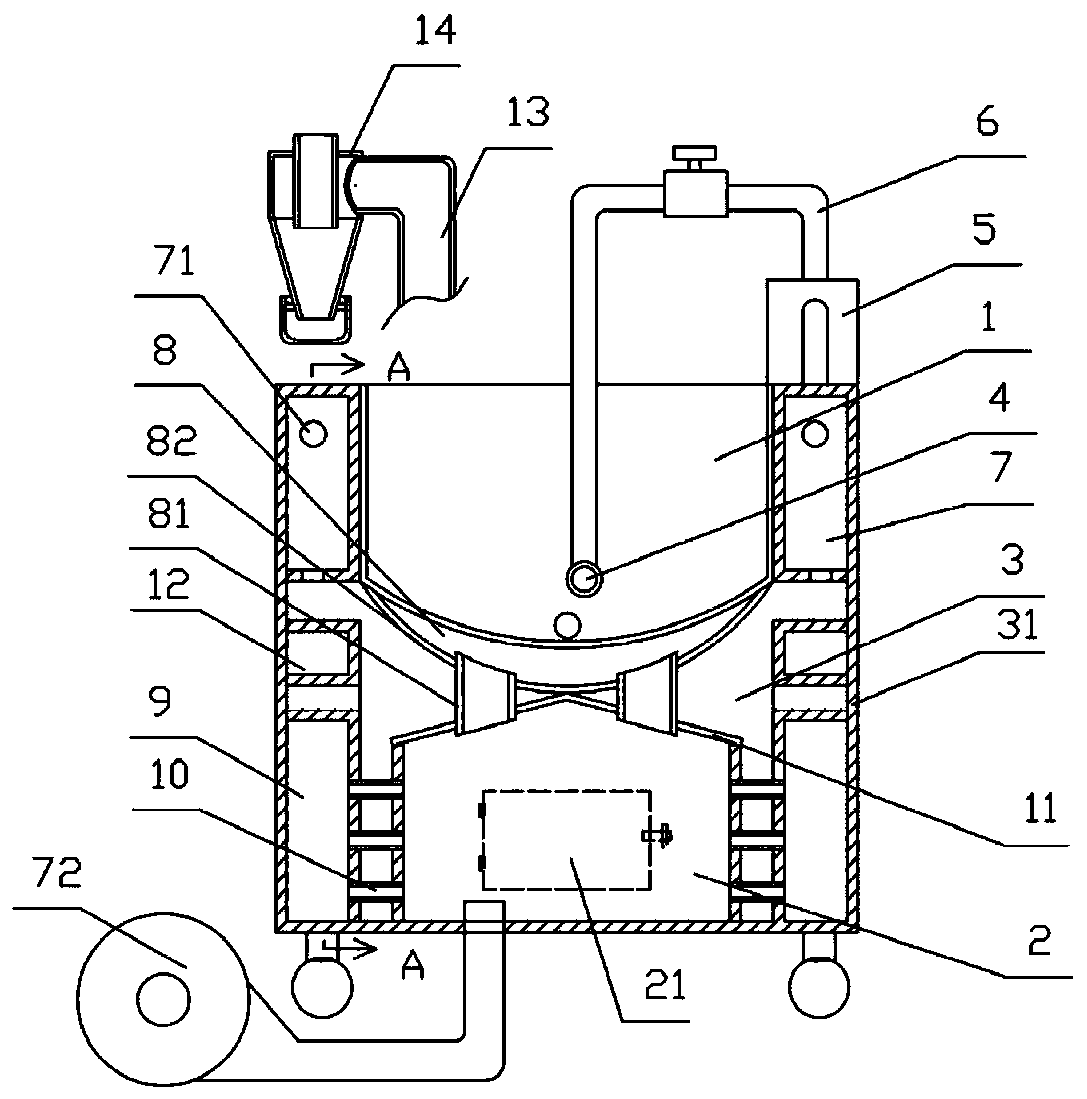

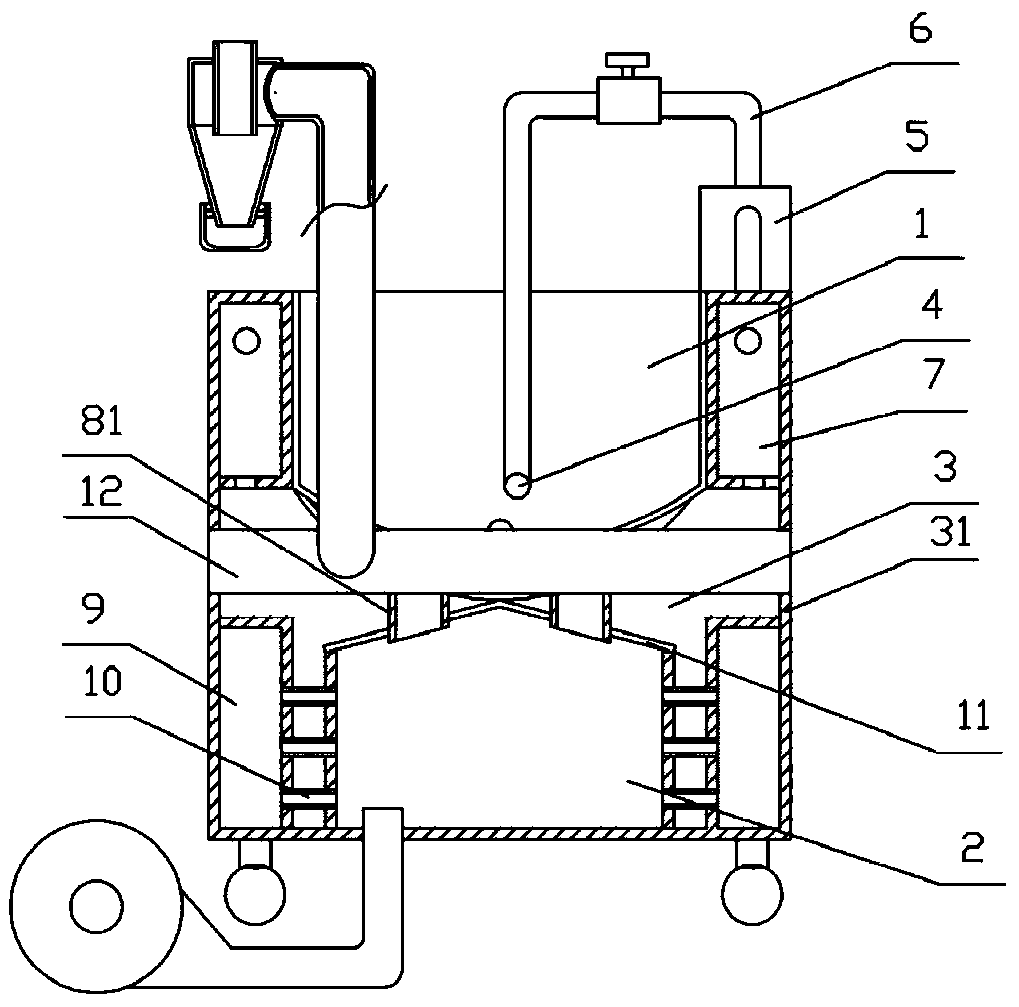

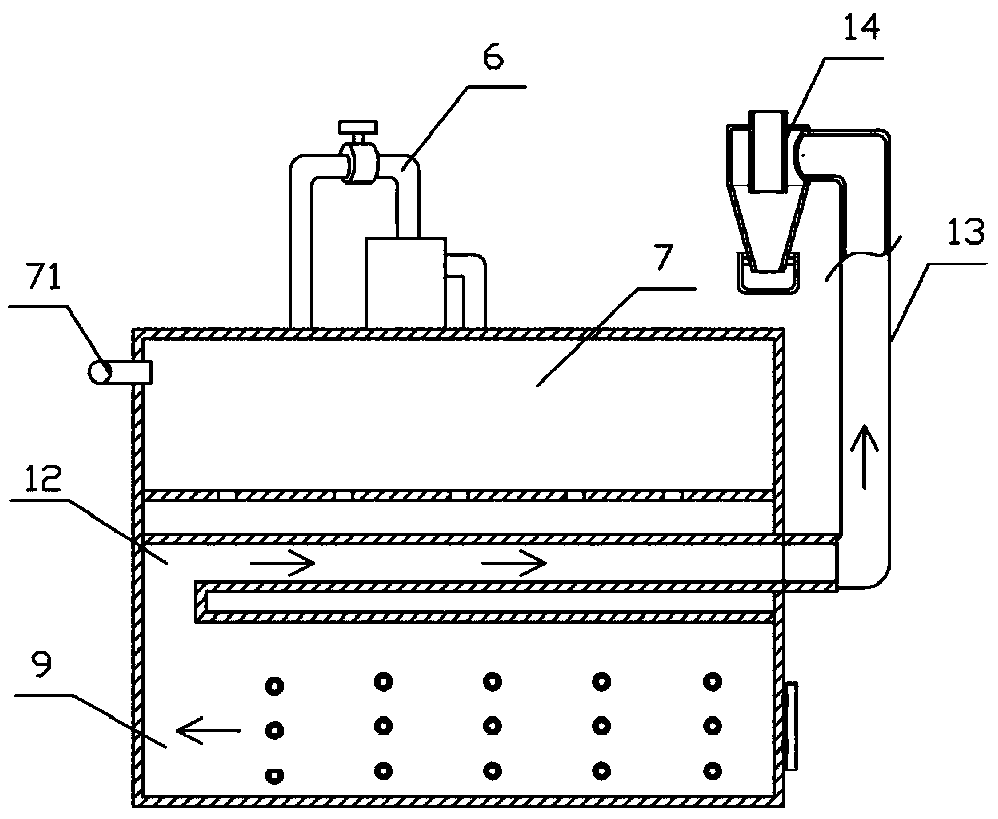

[0015] Such as figure 1 , figure 2 As shown, the integrated pulp cooker of the present invention includes a pot body 1 and a furnace 2 arranged below the pot body 1. The pot body 1 is a U-shaped groove structure with a curved bottom plate arranged on The side wall plates on both sides and the front and rear end plates are welded, and the inner cavity of the pot body 1 forms a U-shaped accommodation space in section. Of course, the pot body 1 can also adopt other structural shapes, such as a spherical bottom or flat bottom, etc.; the upper end of the furnace 2 is provided with a cover plate 11, and the two sides of the cover plate 11 are welded together with the two side walls of the furnace 2 respectively, so that the furnace 2 is formed into a closed space. Of course, the front end of the furnace 2 A furnace door 21 is reserved for adding fuel to the furnace. Cover plate 11 can be a whole flat plate, also can adopt such as figure 1 , figure 2 As shown in the folded plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap